If you are new to the valve industry, it is very easy to feel overwhelmed by the number of different types of valves one might encounter: ball, butterfly, gate, globe, knife, check, diaphragm, pinch, safety relief, solenoids, … wait, what? Are ball valves and solenoid valves in the same category? No, they are not. They both block fluid flow when closed and let it flow when open, but they belong to different worlds – the former belongs to process piping and the latter to instrumentation. To make sense where each type of valve fits – and some types fit in more than one place – codes, standards, and specifications are needed. These documents regulate valve use, and they vary from industry to industry. Read on to learn more about the differences among them and which ones are essential when dealing with industrial valves.

By Davi Sampaio Correia, Technical Consultant

What Are Codes, Standards, and Specifications?

On March 20, 1905, a boiler explosion combined with a fire killed 58 people and injured 150 at the R. B. Grover shoe factory in Brockton, Massachusetts. Today, we do not hear much about boiler explosions, but in the late 19th century, they happened every other day in the United States.1 The Grover Shoe Factory disaster was the proverbial ‘straw that broke the camel’s back’ – as it rallied public opinion to the need of better industrial safety. The present ASME Boiler & Pressure Vessel Code (BPVC) was written by the American Society of Mechanical Engineers as a direct result from the Grover disaster.

According to ASME2, a “code is a standard that has been adopted by one or more governmental bodies and is enforceable by law. A standard can be defined as a set of technical definitions and guidelines that function as instructions for designers/manufacturers and operators/users of equipment.” Those definitions help, but they still leave many people scratching their heads. An example can be used to clarify this system.

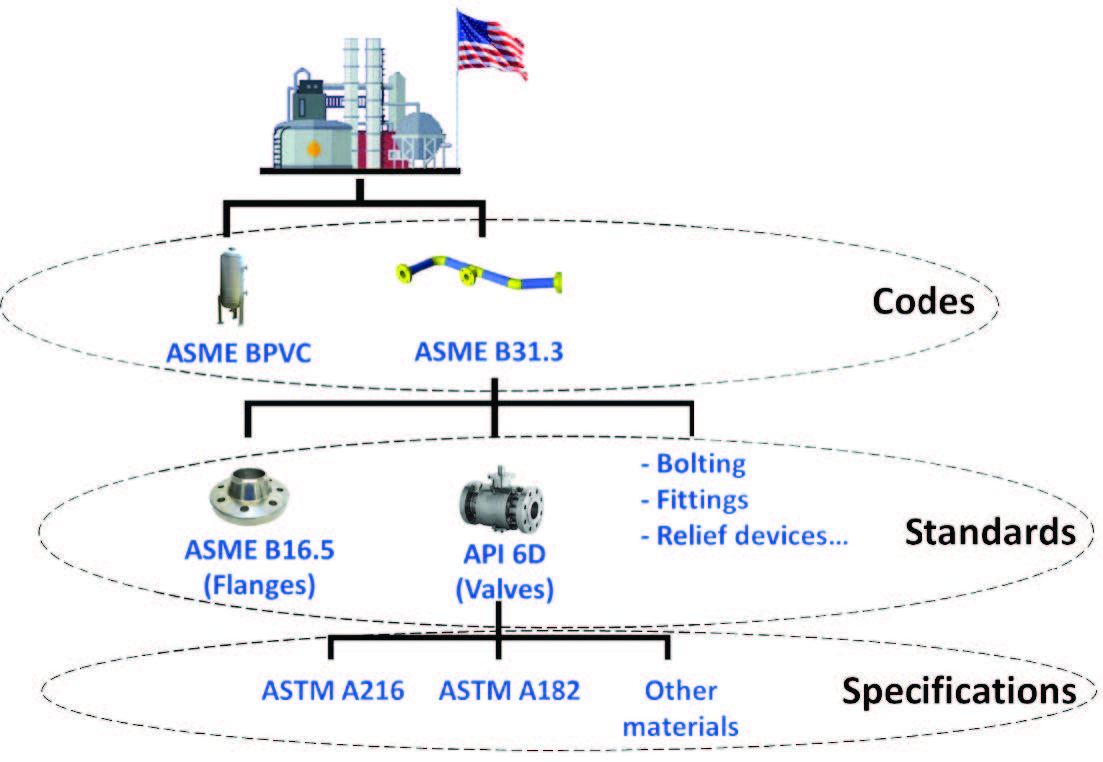

Suppose one wants to build a new refinery. For that among other things, pressure vessels, piping, and valves are required. In the United States, most States have laws that dictate that pressure vessels must be designed, built, and installed according to the ASME BPVC. For piping, a refinery needs another code; the one most used is the ASME B31.3 (Process Piping). These codes specify the minimum engineering requirements deemed necessary for safe design and construction of pressure vessels and pressure piping. And what about valves?

One can think of codes as mandatory design guidelines, a set of instructions to be used when dealing with a ‘system’ such as pressure vessels or piping. ‘System’, in this instance, means that the final product is the sum of many parts. For example, both pressure vessels and piping require, among other things, flanges and gaskets. Codes do not detail everything that goes into the final ‘system’; any industrial product that is required for a system is referred to in a related standard. So, a standard is a document referred in a code that contains instructions on design, fabrication quality control, and testing of a particular item. By using standards, the code gets simplified and ensures that all items used in the ‘system’ are ‘standard’ (uniform in design and fabrication), preventing incompatibility issues and limiting the number of variations for a single item.

Looking again at the refinery example, future piping will follow the ASME B31.3. This code references several valve standards that can be used. For ball valves, for example, one can select API 608 (Metal Ball Valves-Flanged, Threaded, and Welding End) or API 6D (Specification for Pipeline and Piping Valves). For gate valves there is API 600 (Steel Gate Valves—Flanged and Butt-welding Ends, Bolted Bonnets), for butterfly there is API 609 (Butterfly Valves: Double-flanged, Lug- and Wafer-type), and so on.

When people talk about specifications, they can be referring to one of two things. One is a datasheet, that is, the technical requirements of an equipment. For example, annex ‘O’ of the 2014 edition of the API 6D is named ‘Purchasing Guidelines’. On this annex there is a proposed table for a valve datasheet and API 6D states that this table “can be used to assist with the specification of valves for ordering”.

The second possibility of the term ‘specification’ is related to materials. Equipment covered by ASME codes rely on a limited choice of materials. As a rule, pressure vessels, piping, and valves must be made using materials that have mechanical and chemical properties listed on the related ASME code.

Basically, every material listed on an ASME code has an ASTM specification such as ASTM A216/A216M-21 (Standard Specification for Steel Castings, Carbon, Suitable for Fusion Welding, for High-Temperature Service) or ASTM A182/A182M-21 (Standard Specification for Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service). These specifications contain requirements for chemical and mechanical properties, heat treatment, manufacture, heat and product analyses, and methods of testing. Figure 1 provides examples of codes, standards, and materials specifications for an American refinery.

It is also worth mentioning that standards and materials specifications might be amended by the end user. For example, more stringent rules might be forced by contract upon the supplier via supplementary requirements. The S-562 (Supplementary Requirements to API Specification 6D Ball Valves) is a publication from the IOGP with a set of supplementary requirements for the specification for procurement of trunnion mounted ball valves (only) to API Specification 6D Twenty-Fourth Edition, 2014. Ball valves complying with the S-562 have, among other things, more specific design rules and more extensive testing.

Basic Standards Related to Industrial Valves

The takeaway from the previous session is that one can only discuss valves after they have agreed upon which code/standard they must comply with. If talking about a refinery, ASME B31.3 is an option. If talking about valves for the water distribution in a city, then many of the valves listed on ASME B31.3 are of little use. Most likely, the city rely on valves complying with the standards issued by the AWWA (American Water Works Association). Different industries, different codes, different valves. However, that does not mean that we cannot find valves from AWWA listed on ASME codes.

Continuing with the refinery example, the 2016 edition of the ASME B31.3 lists the following standards related to valves. It is worth noting that there are valve standards from four regulatory bodies: ASME, API, AWWA, and MSS.

ASME B16.10: Face-to-Face and End-To-End Dimensions of Valves

ASME B16.34: Valves-Flanged, Threaded, and Welding End

API 6D: Pipeline Valves

API 526: Flanged Steel Pressure-Relief Valves

API 594: Check Valves: Flanged, Lug, Wafer and Butt-welding

API 599: Metal Plug Valves—Flanged, Threaded, and Welding Ends

API 600: Bolted Bonnet Steel Gate Valves for Petroleum and Natural Gas Industries

API 602: Gate, Globe, and Check Valves for Sizes DN 100 and Smaller for the Petroleum and Natural Gas Industries

API 603: Corrosion-Resistant, Bolted Bonnet Gate Valves — Flanged and Butt-Welding Ends

API 608: Metal Ball Valves-Flanged, Threaded, and Welding End

API 609: Butterfly Valves: Double-flanged, Lug- and Wafer-type

AWWA C500: Metal-Seated Gate Valves for Water Supply Service

AWWA C504: Rubber-Seated Butterfly Valves

MSS SP-6: Standard Finishes for Contact Faces of Pipe Flanges and Connecting-End Flanges of Valves and Fittings

MSS SP-25: Standard Marking Systems for Valves, Fittings, Flanges, and Unions

MSS SP-42: Class 150 (PN 20) Corrosion Resistant Gate, Globe, Angle and Check Valves with Flanged and Butt Weld Ends

MSS SP-70: Gray Iron Gate Valves, Flanged and Threaded Ends

MSS SP-71: Gray Iron Swing Check Valves, Flanged and Threaded Ends

MSS SP-72: Ball Valves with Flanged or Butt-welding Ends for General Service

MSS SP-78: Gray Iron Plug Valves, Flanged and Threaded Ends

MSS SP-80: Bronze Gate, Globe, Angle and Check Valves

MSS SP-81: Stainless Steel, Bonnet-less, Flanged, Knife Gate Valves

MSS SP-85: Gray Iron Globe and Angle Valves, Flanged and Threaded Ends

MSS SP-88: Diaphragm Type Valves

MSS SP-105: Instrument Valves for Code Applications

The list of valve standards on the ASME B31.3 is not exhaustive; If one studies the list above, it is apparent that some very common valve standards are missing. For example, the BS 1873 (Specification for Steel Globe Valves). BS 1873 globe valves are routinely used in refineries, but how is that possible if the standard is not listed on the ASME B31.3? The answer lies in dual certification. For the purposes of wall thickness, materials, and pressure-temperature rating, manufacturers use the ASME B16.34 as guidance, while also complying with the BS 1873. That way, a BS 1873 valve is also in accordance with the ASME B31.3.

The standards listed above do not cover all aspects of valve performance required for a refinery application. A typical standard, API 6D for example, has in its table of contents the following sections:

1. Scope

2. Normative References.

3. Terms, Definitions, Acronyms, Abbreviations, Symbols, and Units

4. Valve Types and Configurations

5. Design

6. Materials

7. Welding

8. Quality Control

9. Pressure Testing

10. Coating/Painting

11. Marking

12. Preparation for Shipment

13. Documentation

14. Facility Requirements

15. Annexes

16. Bibliography

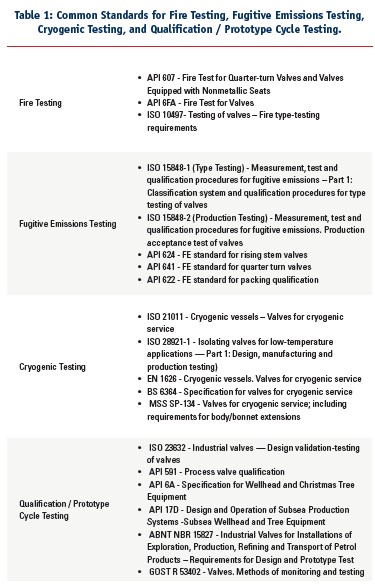

Missing from the list are some very important issues. For example, different standards for Fire Testing, Fugitive Emissions Testing, Cryogenic Testing, and Qualification / Prototype Cycle Testing are often required (See Table 1). These last standards are normally listed in the normative references of the main valve standard that is being used.

Conclusion

Industrial equipment is required by law, contracts, or good practices to rely on codes, standards, and specifications. These documents may vary in different countries – they may even vary within a country – and different industries. Before writing a valve specification or answering a ‘Request for Quotation’, make sure to understand which codes and standards are referred to.