Valves can be found everywhere – in a home, in a car, at a business – but they are not created equally. Sure, they employ similar fluid-controlling mechanisms and may even share some of the same materials specifications, but they differ in one very important way: the standards they comply with. For every application, there is some related standard creating an engineering framework for a valve to be designed, tested, and operated. Read on to learn more about standards and how they help with choosing the adequate valve for an application.

By Davi Sampaio Correia, Technical Consultant

Why Have Standards?

Imagine someone is gifted a piece of meat, some game for example, and they have no idea how to prepare it. Before reaching for a pan, they will likely research some related recipes, which explain what to do and how to do it. There may be many recipes, some more in-tune with specific needs, some more daunting. More often than not, recipes do not explain why the cook needs to perform each step; but despite this, two cooks following the same recipe to the letter should arrive at roughly the same result.

If one can understand recipes, they are more than halfway towards understanding valve standards. Much like cooking recipes, they are a set of instructions on how to accomplish certain things. They have a scope, stating what the standard is for – design, testing, etc. – followed by the specific requirements one must comply with, without any explanation as to why that is so.

Standards exist to prevent incompatibility issues and increase safety. Two valves from different manufacturers that are based on the same standards and specification, will be interchangeable and able to provide the same performance – at least theoretically; a valve can comply with a standard with varying degrees of rigor in design and fabrication. In addition, standards simplify the task of ordering a product; without them, any valve purchase would require book-sized descriptions.

In many cases, there are two types of information in a standard: normative and informative. When something is normative, that means that a certain reference or requirement is mandatory; any deviation from it signifies that the product does not comply with the standard. Normative requirements usually are written using ‘must’ or ‘shall’ to demonstrate their importance. Informative text normally use terms such as ‘should’, and the information they convey is frequently optional. For example, there is a possibility of more stringent parameters for testing or even additional types of testing. Informative requirements may become normative if required by contract.

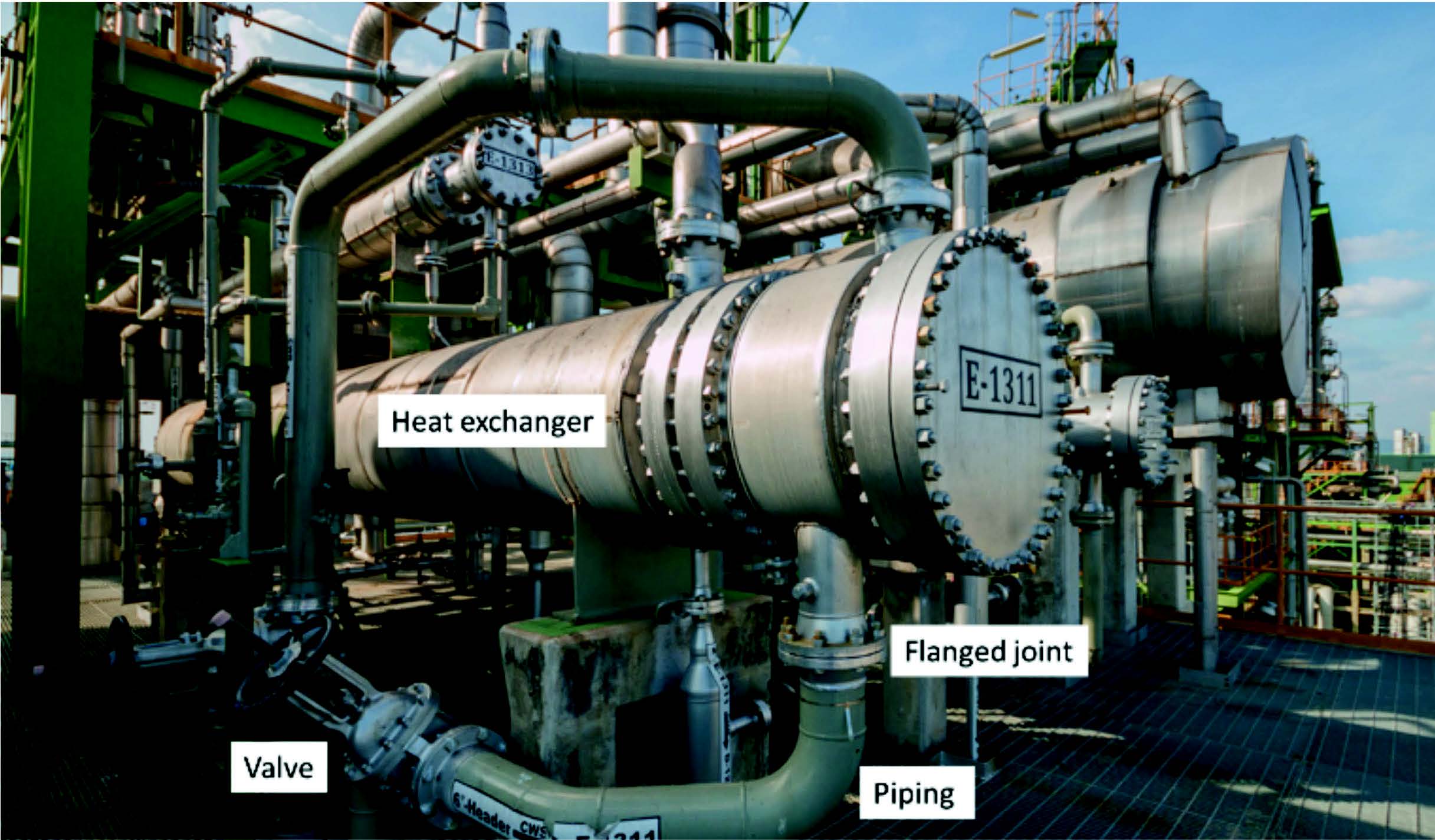

Figure 1 depicts a shell and tube heat exchanger, piping, and accessories (flanges, gaskets, and valves). For any of them, standards are used during procurement. The following are examples of standards that can be used in such application.

Heat Exchangers

Standards of the Tubular Exchanger Manufacturers Association, TEMA, 10th Edition include:

Fittings

• ASME B16.9 factory-Made Wrought Steel-Butt Welding Fittings

• ASME B16.11 Forged Fittings, Socket Welding and Threaded

• ASME B16.25 Butt Welding Ends

• ASME B16.9 Factory-Made Wrought Buttwelding Fittings

Flanges

• ASME B16.5 Pipe Flanges and Flanged Fittings

• ASME B16.20 Metallic Gaskets for Pipes Flanges – Ring Joint, Spiral Wound and Jacketed

• ASME B16.21 Non-Metallic Flat Gaskets for Pipes Flanges

Valves

• ASME B16.10 Face to Face and End to End Dimensions of Valves

• ASME B16.34 Valves Flanged, Threaded and Welding End

• API 6D Specification for Pipeline and Piping Valves

• API 609 Butterfly Valves: Double-flanged, Lug- and Wafer-type

• API 600 Steel Gate Valves—Flanged and Butt-welding Ends, Bolted Bonnets

Different Industries Use Different Standards

Valves standards are everywhere. Plumbing fixtures, such as a faucet, rely on a set of ASME and ANSI standards, such as ASME A112.18.1/CSA B125.1 b (plumbing supply fittings) and NSF/ANSI 372 (drinking water system components – lead content) to guarantee public safety (release of toxic materials) and overall performance.

If faucet design and fabrication is guided by standards, it is no wonder that the same happens to industrial valves. It is important to examine how different industries use different standards.

Figure 2 shows 3 different types of gate valves: a resilient gate, a knife gate, and a slab gate. They serve, respectively, urban water-supply systems, mining, and oil & gas. Each one of these industries uses different standards to define their valves. In other words, one can only discuss valves after agreeing upon which code/standard they must comply with. And that depends on the industry we are talking about.

The valves in Figure 2 comply with the following standards:

a) AWWA C509, Resilient-Seated Gate Valves for Water Supply Service

b) MSS SP 81, Stainless-Steel or Stainless-Steel-Lined, Bonnetless, Knife Gate Valves with Flanged Ends

c) API 6D, Specification for Pipeline and Piping Valves

In the ‘a’ case, valves used in water distribution systems comply with the guidelines published by the AWWA (American Water Works Association). Since 1908, the AWWA has published more than 180 documents covering all aspects of water treatment and supply. The utility truck that can be seen parked next a manhole is probably operating a gate valve designed according to the C509-01: AWWA “Standard for Resilient-Seated Gate Valves for Water Supply Service”.

When moving from example ‘a’ to example ‘b’, the media transition from a clean and safe fluid (water) to a variety of fluids that impose harsher conditions on the valves. So much harder, in fact that valves for the mining industry are commonly referred to as ‘severe service’ valves. For mining applications, the fluid is often a type of slurry: highly dense, filled with solids, and highly abrasive. To make matters worse, corrosion might also play a big part in the challenges the valve must overcome, as fluids can also have strong acidic or alkaline characteristics. Common valve types are knife gate valves (‘b’ in Figure 2) and pinch valves. A common standard for pinch valves is the ANSI/ISA 75.10.01 General Requirements for Clamp or Pinch Valves.

In example ‘c’ there is an API 6D slab through conduit gate valve. One can find this type of valve in offshore (platforms) and onshore applications (refineries and pipelines). A key distinction separates this valve from the ones in cases ‘a’ and ‘b’: the capacity to handle flammable fluids at high pressure (up to #2500 pressure class).

In a refinery, we are dealing with a powerful combination of hazardous fluids, pressure, and temperature; and that begets more stringent rules. An ASME code, such as the B31.3 (process piping), provides the requirements for materials and components, design, fabrication, assembly, erection, examination, inspection, and testing of piping. Listed in the ASME code are several standards covering all the individual parts that will form the piping system: pipes, flanges, gaskets, and valves. For valves, one can choose from many API valve standards and even some AWWA ones. When individuals talk about industrial valves, they are most likely talking about valves that comply with ASME and API codes and standards. However, it is always best to make sure if that is so.

As in many things in life, cost is a main reason to have so many standards. Fewer standards are necessary if the valve is designed to be capable of handling water, mining fluids, and hydrocarbons in high pressure and high temperature applications. However, such a valve would be extremely expensive and a huge overkill for water applications. More standards, therefore means cheaper valves.

It is also worth mentioning that standards might be amended by the end user. For example, more stringent rules might be forced by contract upon the supplier via supplementary requirements. The S-562 (supplementary requirements to API specification 6D ball valves) is a publication from the IOGP with a set of supplementary requirements for the specification for procurement of trunnion mounted ball valves (only) to API Specification 6D twenty-fourth edition, 2014. Ball valves complying with the S-562 have, among other things, more specific design rules and more extensive testing.

Conclusion

Industrial equipment is required by law, contracts, or good practices to rely on codes, standards, and specifications. These documents may vary in different countries – they may even vary within a country – and different industries. Before writing a valve specification or answering a ‘request for quotation’, make sure to understand what the codes and standards are being referred to.