By Brittani Schroeder, Sarah Bradley and Catarina Muia

William Wilson has always felt at home in the field of inspections. Just over a decade ago, Wilson started working for Orbital Engineering Inc., and has moved around within the company several times. His first position involved executing structural inspections for facilities. This included evaluating a plant’s assets, its cranes, and walking working surfaces, among other responsibilities. For this particular role, Wilson worked out of Orbital Engineering’s Granite City, Illinois location. In time, Wilson worked his way up to program Coordinator.

As Program Coordinator, Wilson scheduled the inspections and helped to develop the means and methods for each inspection. “We needed to determine how we were going to inspect each structure, as well as the safety aspects. This involved asking questions like, ‘What parts do we need to lock out for a safe inspection?’, ‘What areas do we need to clear so that we can access the asset with an aerial lift?’, and ‘Do we need a crane and man-basket to properly reach the area?’ Essentially, all of these questions would determine how we would inspect these structures safely and efficiently.”

Wilson was then promoted to Asset Integrity Department Manager for the St. Louis, Missouri office and only two years later, was promoted to Regional Manager. He oversaw the operations at the company’s facilities in Hammond, Indiana; Philadelphia, Pennsylvania; St. Louis, Missouri; and Houston, Texas, where he continues to fulfill his role as Regional Manager.

Never an Ordinary Day

There are many tasks that fill Wilson’s management position. One of these tasks includes supervising all the workers that inspect structures within customers’ metals, bulk handling, refining, petrochemical, chemical, and power generation facilities. These inspections include such things as existing pipe racks, regular and fire-proofed support steel, walking/working surfaces, concrete foundations and decking, and other steel and concrete structures, while also supporting retrofit work. “I oversee what is called ‘boots-on-the-ground’ inspections. If it is any type of steel structure, you can bet that we are inspecting it,” Wilson said. After their inspections are complete, the company will also provide repair recommendations and will prioritize the repairs for the maintenance workers.

In Wilson’s role as Regional Manager, he does not perform most of the plant inspections personally but instead coordinates the field efforts and ensures the company’s deliverables are submitted to all offices on time. With such a wide range of responsibilities, Wilson’s weeks will differ, with some spent in the office and others spent travelling for meetings. While he is responsible for the coordination aspect of the inspections, he is also dedicated to the company’s sales efforts.

The teams Wilson oversees includes more than just degreed engineers. “I work with a fully multidisciplinary engineering team. This includes electrical engineers, civil structure engineers, mechanical engineers, designers, and inspectors with a technical background,” Wilson states. “Our technical inspectors are taught by our engineers and go through a very robust training program.”

A large part of Wilson’s job is to make sure all inspectors understand how to recognize different structural components and find where the key problems are. The inspectors need to have the ability to identify and know where problems are going to occur in a plant, they need to know whether or not the environment is corrosive or caustic, and know how to document all of this information in a formalized report. The report is used to provide information to engineers so that, if there is a need to develop a retrofit design repair for a specified structure, all the information is readily available.

New Inspections and Challenges

Each inspection that is performed by Wilson’s team is different, and that is what he enjoys most about his job. “One day I am in a plant and performing inspections with my hard hat on, the next day I am dressed up and sitting down at sales meetings, and the next I am going to lunch and learns,” he explains, “I really enjoy meeting new people and networking with potential new clients. I can appreciate people who do the same thing every day, but I do not think it will ever be for me.”

When asked about what challenges him the most, Wilson admits, “it is more of a frustration than a challenge.” The inability to give his clients an answer or a solution right away is something that prevents him from completing a task. “I feel as though I let them down, but then I go and look deeper into the problem to find a solution.” If Wilson and his team do not have a solution in-house, he reaches out to other SMEs at the other five Orbital offices to find the solution.

Inspection Areas

When looking at structures, the most common problem that occurs is corrosion/degradation of the materials. “We are looking for holes in beams, cracked welds, and missing bolts or rivets. We are looking at all the structural components associated with assets to identify where the problems are occurring,” says Wilson.

His team has also been conducting more walking-working surface inspections. These inspections work toward the effort to make all aspects of a plant as safe as possible to comply with OSHA standards. Before an outage is initiated and workers are assigned to an inspection or maintenance task, Wilson must ensure that any team entering the area to work will be safe. This can be as simple as ensuring that the staircases have sturdy handrails or that the ladders are secure. “Most people assume that the structure is safe to use, but they are not looking for structure integrity like we are.” It is common that engineers will focus on the valve or application that needs to be fixed, rather than focusing on the safety of the task at hand. “It is our job to make sure they are safe, to be able to tell them how to repair their assets, make sure the repairs are done correctly, and suggest how to run their plant maintenance correctly,” Wilson continues.

Turnarounds on inspections can also vary greatly and are typically determined by the component or area that is being inspected. If the team is only inspecting one unit, the task might take only one day to complete. If the team is inspecting a whole plant and all of its walking-working surfaces, the task could take anywhere between two weeks to one month. “We have a tablet-based inspection process that we utilize in the field, which then allows us to send our results to the client right away so they can begin repairs the next day. The goal is to get the information to our clients in the quickest, yet most thorough way possible.”

A Variety of Projects

Wilson describes his team as being “well-diversified”. The team will work in any type of facility including metal production, petrochemical, oil and gas refining, mining, railroads, and power generation. The majority of assigned tasks consist of brownfield projects, which include inspecting already-standing structures and aging infrastructure. Orbital Engineering has developed its own proprietary software program to complete more condition-based risk assessments on structures, which is a direct result of over fifty years of experience performing structural inspections, engineering and repairs all while lacking a standard set of industry codes to follow. This program helps both Orbital’s clients and its inspectors.

The inspection team also has approximately 30 standard repair procedures developed in-house. Among these procedures are how to repair a cracked weld, how to repair a hole in a beam, how to repair concrete and fireproofing applications, and how to replace bolts. These standard procedures are documented and included in the inspection reports to enable a seamless hand-off for the repairs to a subcontractor who can properly complete the task.

The inspections also determine whether or not repairing or replacing components or applications will be more cost-efficient for the plant. “It is all about finding the best solution. For example, if we are inspecting a unit made of carbon steel, we may say it needs to be galvanized, or the plant requires a certain sensor type and coating to prevent further deterioration. If it is a hole in a beam, we can determine that it is actually more cost-effective to put a patch plate in the beam rather than replacing the whole thing. Preventative maintenance is key,” Wilson stresses.

There are a few procedures that Wilson suggests can help in preventative maintenance. “Clean off your structures on a routine basis,” he emphasizes. A regular occurrence Wilson has noticed throughout the past few years, is a reduced budget for coatings. While money is being directed towards other plant priorities, the condition and upkeep of the structural steel suffers. By keeping coatings up-to-date, further damages and deterioration can be prevented.

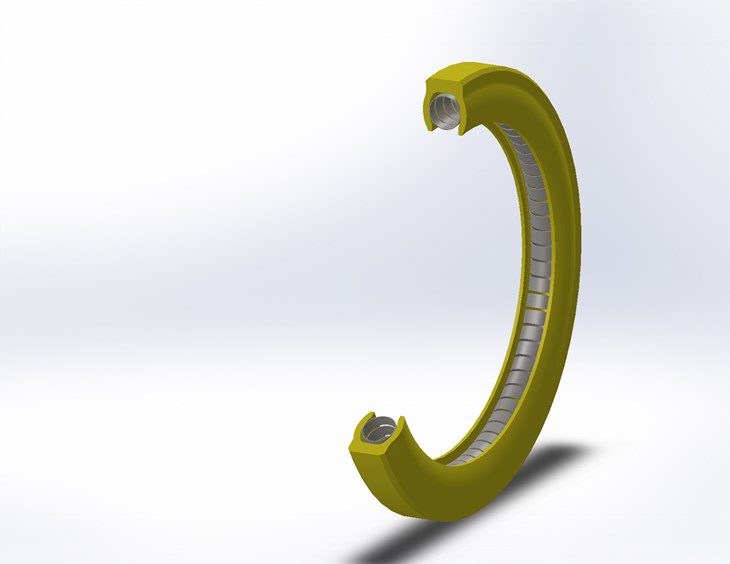

Valve Inspection

Wilson and his team execute plenty of mechanically-based inspections. “We do a lot of American Petroleum Institute (API) inspections, including 510, 570, and 653 among others,” he says. When it comes to specific applications such as valves, Wilson’s team is involved with spill prevention, control, and countermeasure (SPCC), which is typically applied across all industries. When a valve leaks, Wilson’s team will identify where the leak is coming from, recommend repairs, and support the repair contractors through the process.

Supporting companies through repairs includes everything from the initial inspection, to finding and hiring a contractor to do the repair, all the way to the completion of the job. “We fill the work order, then validate and verify that the repair has been completed. Sometimes it is a repair situation, and sometimes it is a replace situation, and we are there through it all.”

When it comes to hose inspections, Wilson typically works in desert areas where dry rotting is a frequent concern. Sandstorms and dry air negatively affect the hoses. When the application has undergone these environments extensively, the material of construction can be impacted. When this deterioration is experienced, the product must be replaced immediately.

Aging Infrastructure

As aging infrastructure is a growing concern, Wilson is preparing his team for the inspections he sees coming down the line. “Older facilities are going to become a problem—that is a fact. It has already started,” Wilson states. “Some plants that have been neglected for years, handle coal or other caustic substances, and therefore the plants and its components are being attacked by those same substances.” Plants that are located along the Gulf of Mexico are also being attacked by the environment, which includes salt from the Gulf’s waters or hurricanes. Any inspections and repair recommendations of older facilities need to comply or at least be reconciled with the new industry codes, and any corrosive material handling needs to be treated with more care.

The goal is to develop more preventative maintenance approaches for these facilities during the inspections. However, Wilson’s team finds many of the plants are reluctant to use their own budgets. Wilson intends to help “knock out” the higher priority deficiencies in the plants that are easily identified and create a plan for the maintenance teams to carry out. “If we remove the big problems, we can increase the efficiencies in the plant and gradually address everything else that needs to be done.”

Technology

A new technology that Wilson has seen in the field of corrosion prevention is the pulsed eddy current non-destructive testing (NDT). It is an advanced electromagnetic inspection technology used to detect flaws in ferrous materials typically hidden under layers of coating, fireproofing, or insulation. For Wilson’s team, the tool is predominantly used to detect imperfections in fireproofing layers. If there are voids or cracks in the fireproofing layers, water and other moisture can start attacking the structural steel underneath, which will lead to accelerated corrosion and other forms of deterioration. With the pulsed eddy current, the inspection can occur without removing the layers of fireproofing—which would then have to be replaced after the inspection was complete. This type of NDT simplifies the process, which is helpful to Wilson’s team and the people at the facilities.

A Lifetime of Learning

As the plants age, so too do the operators that handle the assets. “You should want to leave the plant in better shape than when you found it,” says Wilson. This thought drives him and his team as he goes out for inspections. “We see an aging workforce, and when we come across those who are close to retiring still working in a plant, I just want to put them in the same mindset. Why should a person leave and take all knowledge and experience with them, without sharing with other engineering, operations, or maintenance personnel? If we are able to share that information, the plant and other engineers will be much better off for the future.” Wilson is driven to positively influence engineers and operators today, in order to make the new generation of industry workers, successful.

Networking for the Future

In order to pass along knowledge for future success, Wilson recommends that the new generation of industry engineers and operators attend and prepare presentations for as many conferences as possible, as it will give them the chance to learn from industry leaders. “It is always a good thing to go and see who attends the exhibitions and participates in the conferences. It is a great way to scout out new potential customers or suppliers, and then you can go back to your company and tell them about what you learned,” Wilson explains.

Wilson also emphasizes the importance of these events for networking opportunities. “Meeting and getting to know people who are the subject-matter experts is a great opportunity. You will never go wrong sitting in on a conference session and actively participating in conversations with other industry professionals.” Wilson often considers social media networking as superficial, because it is never the same as meeting someone face-to-face, and building a relationship is best done in person. “That is why a conference like Managing Aging Plants is so successful for inspection teams. We can meet with the people attending and learn how to better serve the industry.”