Refineries (hydro treatment processes, cracking, etc.) and the chemical industry (ammonia and methanol production, food chemistry, synthesis, etc.) account for the largest share of this usage. Due to the changing policies towards decarbonizing the energy sector, hydrogen as an energy carrier, ideally produced with low CO2 emission methods, is increasingly in focus. In addition to industrial use in chemistry, petrochemistry, and refining, future applications focus on the steel industry, fuel cell mobility, as well as stationary and mobile applications.

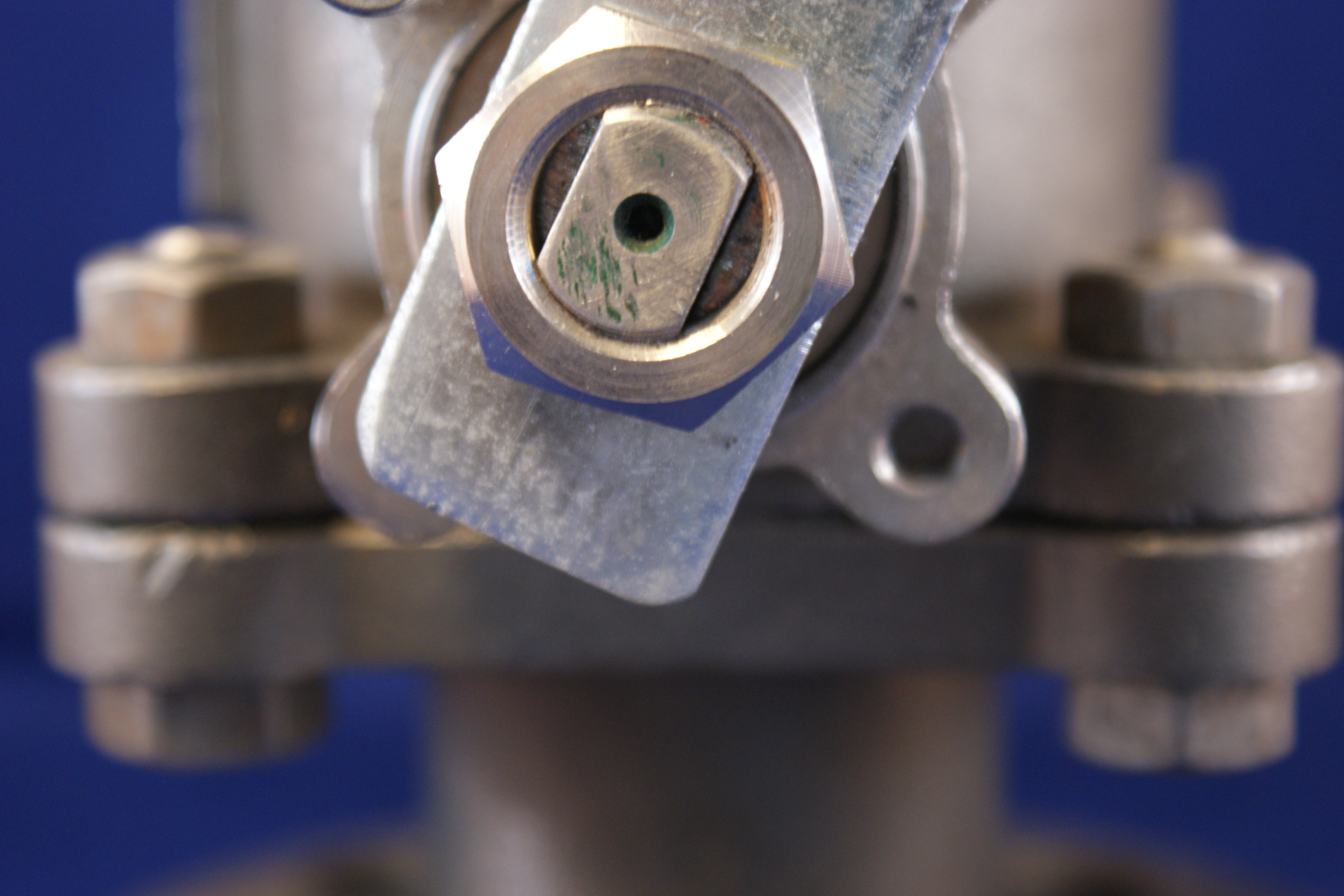

Hydrogen-compatible ball valves

The application possibilities are as diverse as the valves required for hydrogen production, storage, and transport. The valves used along the hydrogen value chain must meet stringent safety, design, material resistance, and quality requirements, not least because hydrogen, as the lightest element, is highly diffusive. Furthermore, the valves must withstand extreme pressures and temperature ranges.

Courtesy of Klinger.