Data has recently been presented that suggests that 80% of hazardous fugitive emissions come from ball valve stem leaks. To mitigate the threat of these emissions, several new technologies and devices have been designed.

By Bob Donnelly, Contributing Writer

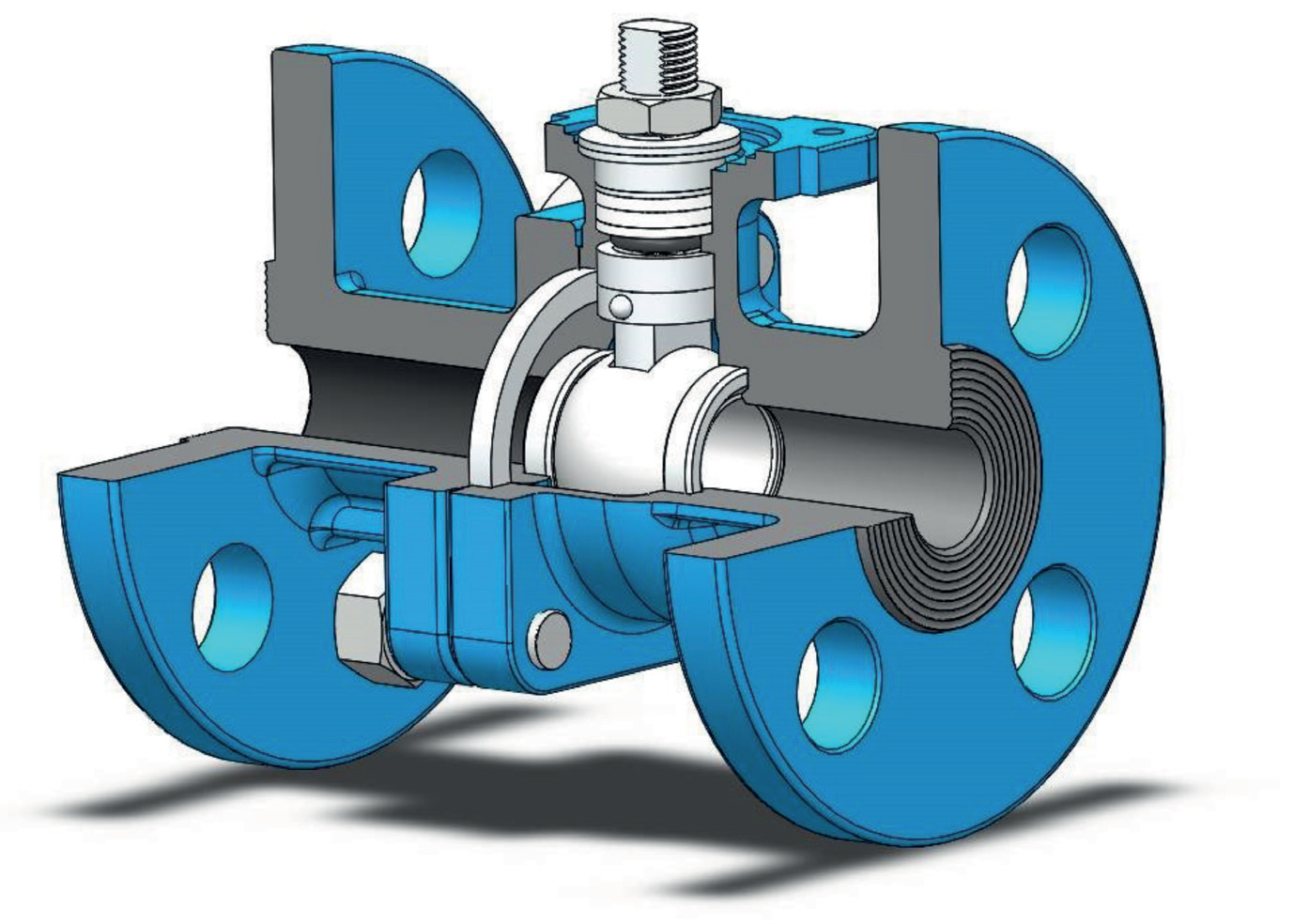

One technology that has become more prevalent in the industry is media containment devices. Media containment devices have been designed to deal with emission-specific problems by providing a secondary sealing system that controls any leakage and allows the valve to continue in service until normal routine maintenance is scheduled.

Device Capabilities

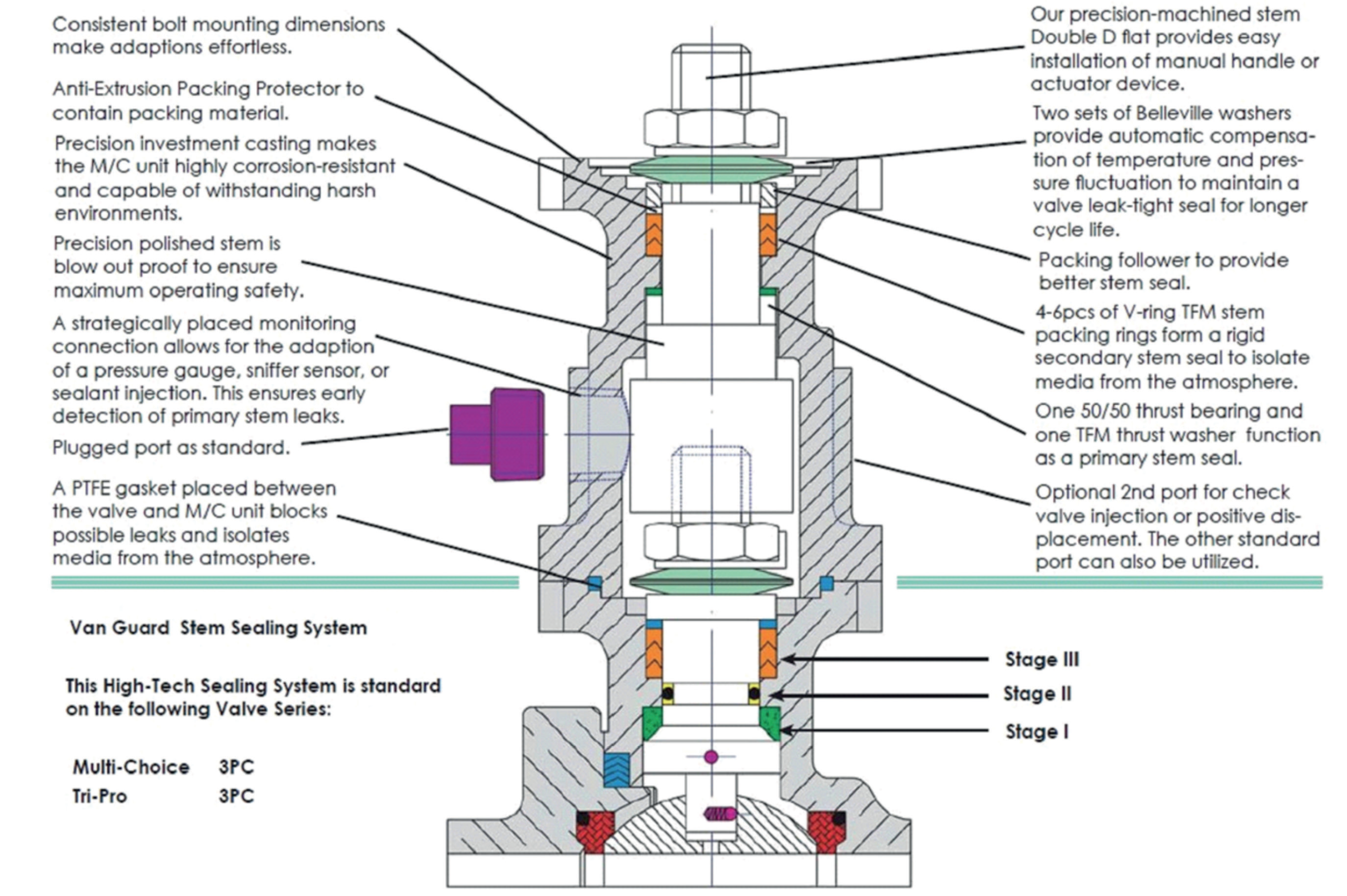

In any industry that uses ball valves in their process control applications, one of the primary concerns is the potential leak path through the valve stem seals caused by repeated cycling of valves over extended periods of time. Media containment devices, such as the ISO-15848 (Illustration 1), contain two sets of Belleville washers that provide automatic compensation for temperature and pressure fluctuations to maintain a leak-tight valve seal that prolongs the cycle life of the valve. They also have 4-6 pieces of V-ring TFM stem packing rings that form a rigid secondary stem seal to isolate any media from the atmosphere. Additionally, a 50/50 thrust bearing and a TFM thrust washer also function as a primary stem seals. A precision polished stem is blow-out proof to ensure maximum operating safety.

These devices also have a strategically placed monitoring connection that allows for the adaption of a pressure gauge, a sniffer sensor, or sealant protection. The additional safeguard additions allow for the early detection of primary stem leaks.

Another prevalent technology used to reduce emissions is the stem sealing system. This system has multi-layer V-style packing rings, O-rings, and thrust washers to isolate any leakage paths. The combination of washers incorporates double deflection under the same nominal load that in turn makes the stem packing assembly live-loaded (Illustration 2).

Proactive Measures

In the event of an unexpected leak, the use of a secondary application to reduce the harmful consequences of having to wait for a permanent solution can significantly mitigate the amount of fugitive emissions that are able to escape. In the event of the detection of a hazardous emission, the maintenance engineer can immediately mount the device on the valve with the problem, thus isolating the leak. By isolating the leak, operators can avoid the costly consequences of shutting down the line and having to implement other routine emergency actions. The device will allow for continuous process control operations until routine maintenance is scheduled.

As a preventative measure, these devices can also be ordered mounted on valves as a positive insurance solution; they create a secondary layer of leakage isolation when the valve is placed in service.

In the event of an unexpected leak, the use of a secondary application to reduce the harmful consequences of having to wait for a permanent solution can significantly mitigate the amount of fugitive emissions that are able to escape.

Final Thoughts

When considering the potential costs associated with a plant shutdown, including the liability-related issue, having a preventative measure in place can have a significant impact on the efficient and effective management of a plant. Although it is the ball valve that is noted for its leaking potential, a containment device could be used to mitigate the negative impact of fugitive emissions for any valve used in critical service.

There are therefore several innovations available to help mitigate the effect of hazardous emissions and all of the costly ramifications if they are not addressed.