The prospect of green energy or carbon reduction may seem like a threat to many professionals in the valve industry. In reality, the industry focus shift toward carbon management provides the valve industry and a net-zero future with symbiotic opportunities.

By KCI Editorial

A Look at the Energy Industry

There has been a collaborative and concerted effort from groups to shift humanity towards carbon reduction, and ultimately a net-zero future. However, society, as it stands now, needs the current energy apparatus to continue to function. Transitioning completely to green/renewable energy is not currently viable. Instead, a more pragmatic approach is the capturing and sequestration of carbon emitted from traditional industries. This is what is known as carbon capture and storage (CCS), and it is not a threat to the valve industry, but a new frontier.

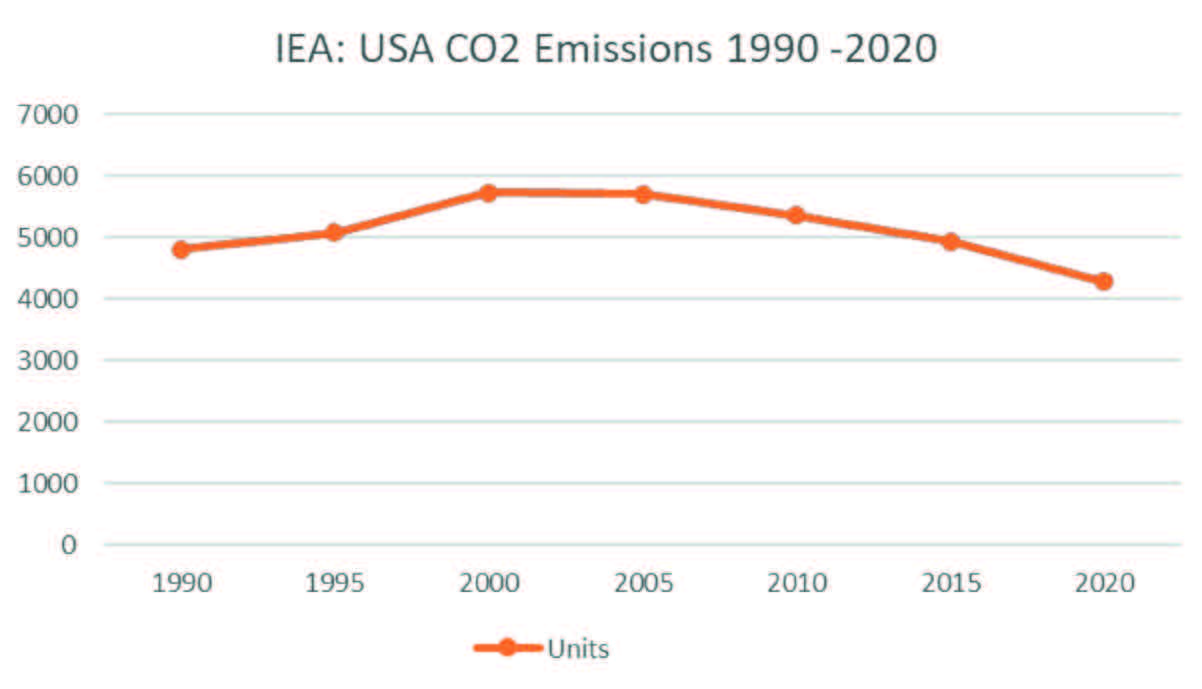

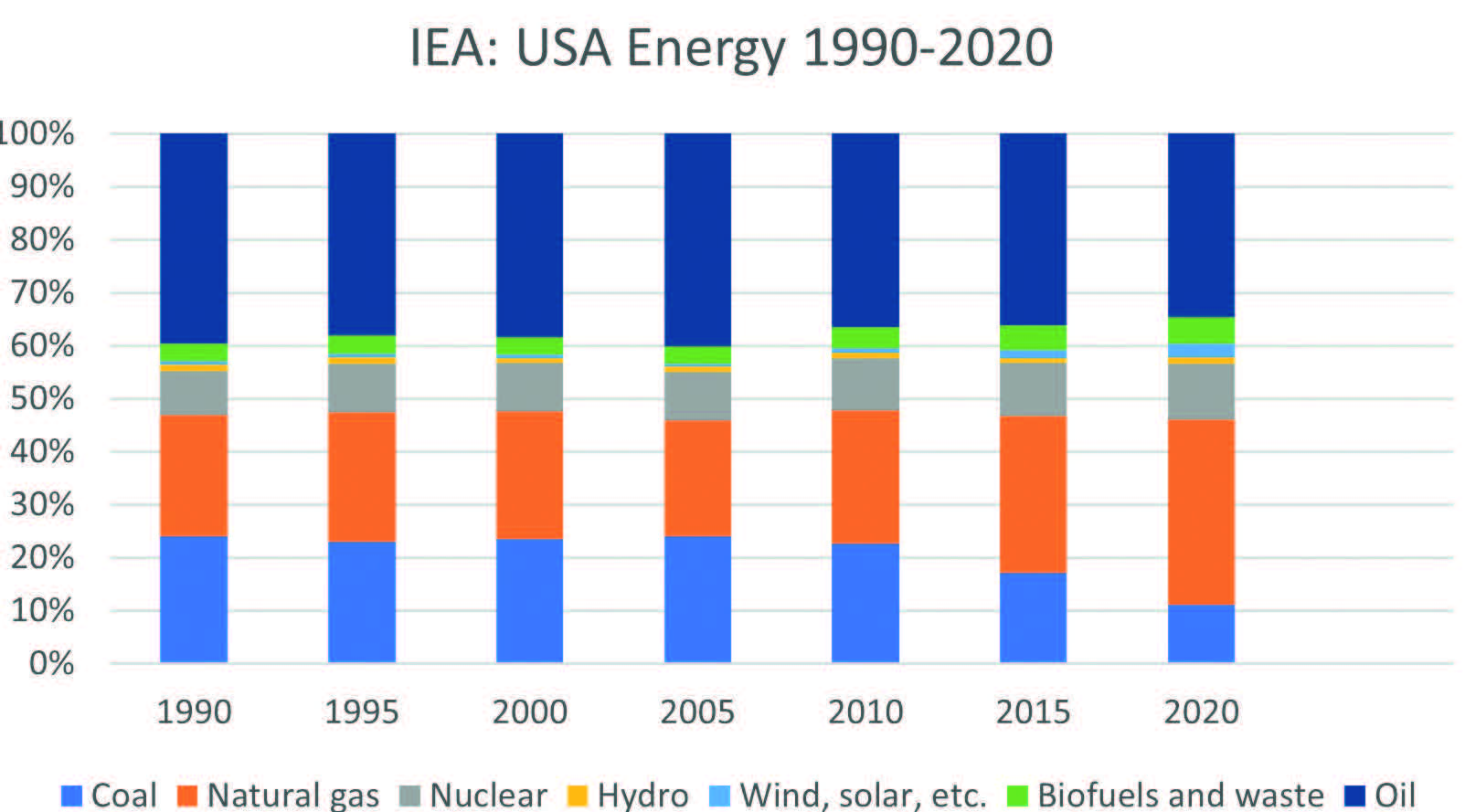

Despite all the talk about green energy, the United States’ energy portfolio continues to be carbon exhaustive. In 2020, oil alone accounted for nearly 35% of the country’s total energy production, while green energy accounted for roughly 9%; in 1990, oil represented 39% of the production while renewables sat at 7%1, see Figure 1.

In 2020, the U.S. produced 30% more energy but produced 10% less CO2 emissions than in 1990. Its energy strategy over the past 30 years has focused on carbon management. This is illustrated with the United States Office of Fossil Energy and Carbon Management’s (FECM) R&D budget. In 2012, FECM’s CCU funding budget was USD $66 million, in 2020 the FECM received upwards of USD $320 million for CCU R&D. 2

CCS fits the carbon management profile; it not only has the potential to help reach a net-zero goal, but, in theory, has the potential to become a carbon negative technology, although none of this becomes reality without the valve industry.

What is CCS?

With almost a 50 year history, CCS is not considered a new technology. Recently it has entered back into the contemporary lexicon, and for good reason. CCS is among humanity’s best solutions for reaching a net-zero future. CCS allows for the capture of carbon after it has been emitted, giving countries and industries dependent on fossil fuels the flexibility to maintain existing energy infrastructure while mitigating their emissions. CCS can be broken down into three key

steps.

Capture

CO2 can be captured from large-scale industrial projects’ smokestacks, including power plants, manufacturing, concrete, petrochemicals, steel manufacturing andother carbon-intensive industries. This can be accomplished through several different methods including use of membranes, combustion, absorption, and others.

Transport

The captured CO2 must be transported to natural storage sites that are often hundreds of miles away from the source of the emission. Transporting the carbon can be done by rail, truck or ship. However, pipelines are the cheapest form of transport.

Storage

After arriving at the site, CO2 is injected deep into natural underground reservoirs. Often, the carbon is deposited into geological formations like oil & gas fields that use geochemical trapping mechanisms to keep the CO2 from escaping to the surface.

Developing Scale

CCS technology first rolled out commercially in the 1980’s but has been slow to be adopted. This may soon change as carbon capture could be on the cusp of a meteoric rise. Since 2019, there have been 27 operating commercial CCS facilities in the world. In 2021, roughly 40 million tons of carbon was captured with these facilities. This number has more than doubled since 2010 and has quadrupled since 2000. The sector is experiencing never-before-seen growth. In 2020 there were 21 facilities in advanced development, which represented a 110% year-over-year increase from 2019. Also in 2020, 38 new facilities were announced, while in 2021 these figures exploded to 66 facilities in advanced development, with another 97 announced.

In 2021, global funding for carbon capture jumped more than four-fold to 1.4 billion. By 2050, carbon capture start-ups are estimated to be worth USD $1 trillion.6 Though trending in the right direction, the industry still requires tremendous scaling.

The International Energy Agency has set benchmarks for the wide scale adoption of CCS, and while the project is not on track, with a 2020 IEA report asserting that storage must be increased to 5.6 billion tons per year to meet climate goals, the wider adoption of the technology is underway.

Large investments showing faith in the technology have made the carbon capture market a more attractive investment opportunity, spurring plans for over 120 new industrial CCS projects across the globe; with investments in China, Europe, Canada, and the United States.

Valves and CCS

The widespread implementation of CCS as a solution for hard to abate industries, including but not limited to traditional energy production, is a possible future. In this future, vast amounts of infrastructure will be needed to transport captured carbon to permanent storage.

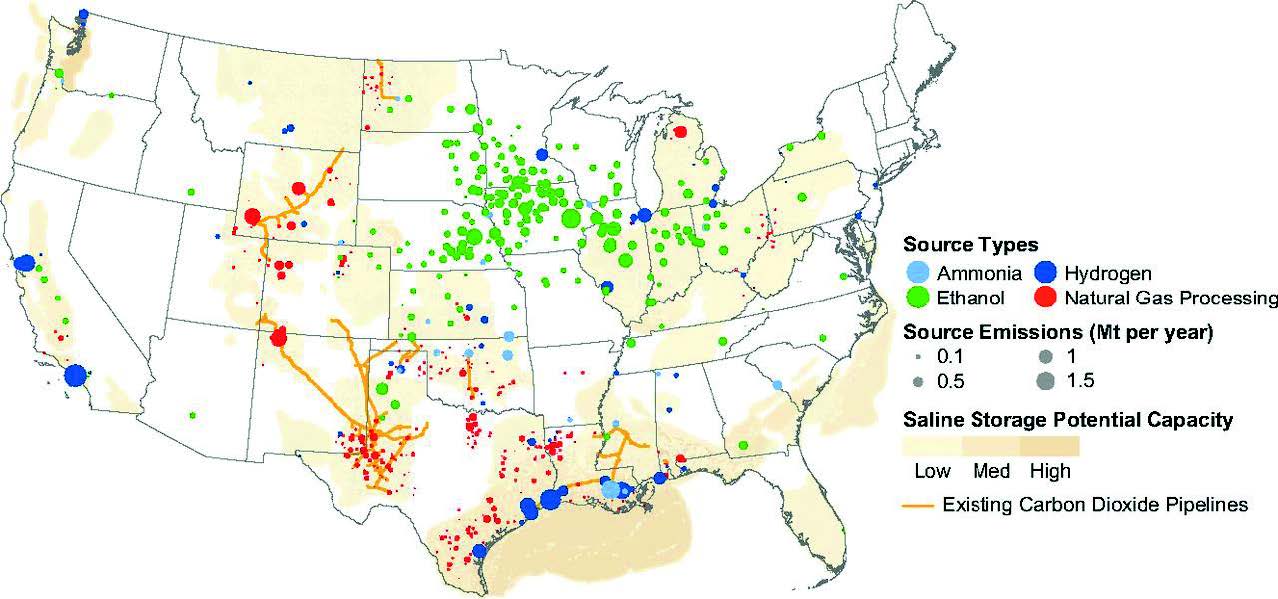

In the United States, CO2 sources, and geologic reservoirs are separated by a substantial amount of space and geographical barriers. Therefore, for CCS technology to scale and become widespread new dedicated CO2 pipeline infrastructure will need to be constructed.

In 2018, it was found that without dedicated infrastructure, like new pipelines, the United States could transport 19 million tons of CO2 per year while still being profitable.8 For reference, a 2021 Princeton University study has determined that If the United States is to deliver on its net-zero target it will need to be capable of moving at least 65 million tons per year by 2030.9

As of 2022 there are just over 5,000 miles of dedicated CO2 pipelines in the US, but this could soon change. Interest in the United States is being driven by federal and state incentives for CCS, and low-interest loan programs for CO2 pipelines. This was passed by Congress in 2021 and has received support from the Biden administration to grow the ‘carbon management’ industry in an effort to reduce emissions.

As investment pours in for CCS, it is estimated this mega infrastructure project will cost billions to complete and will include backing from the United States government and commercial organizations.

The prospect of this potential massive pipeline infrastructure project is worthy of the attention of the valve industry. By 2050, pipeline infrastructure for CCS is estimated to be between 60,000 and 310,000 miles in length.

Given that CO2 is increasingly toxic at concentrations above 7%, any failure in such a pipeline could lead to the release of a significant amount of toxic inventory. As with any piece of critical infrastructure, safety for people and the environment is of extreme importance, and it has been suggested in two separate studies that any CO2 pipeline’s emergency shut-off valves should be spaced between three and 15 miles.

Aside from emergency shut off valves, a bevy of midstream API 6D pipeline valves will be needed in conjunction with valves for separation facilities and compressors for high pressure pipelines.

There is talk of reviving and retrofitting existing natural gas pipelines. However, as carbon travels at a much higher pressure compared to that of natural gas, the upgrade would be expensive and extra safety precautions would be needed to avoid the pipeline cracking underground.

When the carbon arrives at its final destination, the CO2 needs to be injected deep underground into geological formations. It is commonplace today to use injection wells to accomplish this. Rather than pumping fluid like gas or oil, CO2 is compressed and pushed deep into the Earth under extreme pressure. This pressure calls for the use of compressors, piping and, of course, valves.

Other Types of Carbon Sequestration

As investment ramps up for CCS the technology, at a minimum, shows promise of further development and innovation.

In April 2021, XPrize, a non-profit organization that creates and hosts public competitions intended to encourage technological development for the benefit of humanity, partnered with Elon Musk to create a competition for the best carbon removal technology. The prizes, totalling $100 million, will be awarded to the best carbon negative solutions, with a grand prize being awarded in 2025.

Direct air capture (DAC) is an extremely flexible technology that can be used anywhere in the world. DAC combined with storage (DAC+S) can capture CO2 directly from ambient air and store it underground.

Instead of carbon capture and storage, carbon capture utilization (CCU) is the process of capturing CO2 and recycling it for further usage. At this point the principle needs further research and development before it is considered practical from an economic standpoint, though there is hope that CCUS has tremendous room for innovation.