Valve World Americas spoke with Founder and CEO Wayne Fleming and President Randy Estes to discuss the Chelsea, Alabama-based company’s success in its 20th year in business, expansive line of engineered products and drive to provide customers with a complete quality package.

By Sarah Bradley

Founded in 2001, VAC has maintained a strong presence in the valve positioner market over the past 20 years with their European manufacturing counterparts, through producing universal designs that can be mounted and calibrated to all leading valves and actuators on the market. By focusing on valve positioners and the accessories to support those primary products, VAC has made these unique instruments their main focus, ensuring that they are partners with their core customer; the valve and actuator manufacturers.

After two decades in business, VAC’s market strengths are independence, service, quality and their talented team. As a privately held entity, VAC is not controlled by a large board, which allows for decisions to be made quickly and with their “customer first” philosophy.

“The company started 20 years ago with two people and we have experienced significant growth over the years, but the most important thing is that our vision has never changed,” said Wayne. “I attribute our longevity to our commitment to hiring quality people, giving them the tools to be successful and while adopting the values that we believe makes us stand out in the business. Our business begins with a solid product design, quality construction and ends with a very satisfied customer.”

Products Positioned for Success

“We think it is important for the industry to recognize that positioners are an engineered product. It may be considered an accessory, but it is a unique precision instrument that is a very important component in controlling the flow via actuated valves,” explained Randy. “It is easy to find a simple positioner, but what differentiates our product in the market is the high level of accuracy, repeatability, and lifespan.”

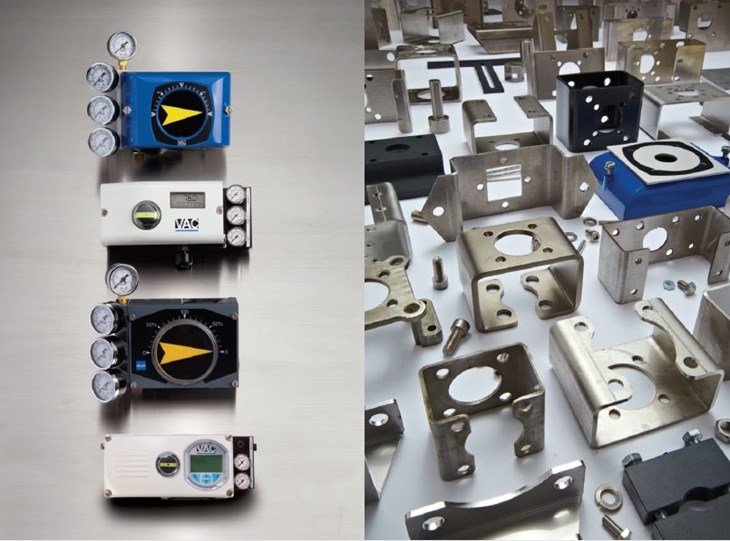

VAC entered the business with its flagship V100 product, which is still a tried, tested and true cornerstone of their product line. Known for its durability, the V100 is constructed of cast Aluminum with polyester housing that is NEMA 4X rated, all stainless steel retained fasteners, a thick stainless steel cam that is double locked with sturdy cam nut and the bottom plate helps absorb vibration. Screwdriver slots in the span and zero ferrules, along with an external zero adjustment, helps make setting up the positioner simple. Special cams, range springs, various pilots, spindles (drive connectors), gauges, dome indicators, and position feedback are examples of the options that are available from VAC. The V100 features one housing for pneumatic or electro-pneumatic, where an I/P can be installed, removed or upgraded (i.e., IS, Ex, etc.) at any time, while still mounted on the actuator. The V100 has various mounting capabilities – rotary or linear — in the shop or field. Multiple indicator options which include a large, flat pointer indicator or a raised beacon are available to meet various applications. This includes large pointer indicators or beacons.

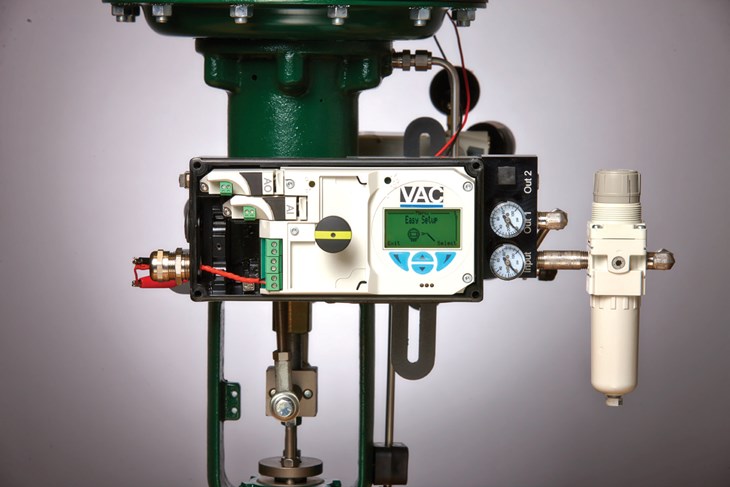

With their manufacturing partners in Sweden, the company began to develop products that grew with the industry to offer new accessories and features. The compact NEMA 4X V200 valve positioner series allows for an internal I/P, switches, 4/20 mA transmitter, all in one compact, rugged die-cast aluminum housing. Both Zero and Span can be adjusted without removing the cover, and the single spring has very little interaction. Being able to get all of the needed options from a single product can be a real benefit. As the need for valve position feedback grows, the V200 positioner allows for various internal feedback to meet many application needs. VAC’s attention to quality but flexible mounting kits expands their market opportunities. Additional features like various pilot assemblies, special cams, various I/Ps to meet a wide range of industry needs all help make the V200 a “complete” positioner offering.

“The industry has done a good job of convincing customers that digital is better than analog, because you can push a button and it works, but that is not the case. We have tested our V200 and had it surpass many of the digital positioners available, because it is easily calibrated, simple to use and is just as accurate with a low cost of ownership,” explained Randy. “Our core value is to fulfill the customer’s needs — we are not going to tell them what their needs are. Many companies will try to push for the most expensive option because their focus is on making a bigger sale. We are not in the business to force our customers to buy into a product that they do not need. The longevity of the relationship with our customers relies on educating them and providing them the best product for the application, not trying to push them into purchasing a more expensive product if it is not necessary.”

“We make a sincere effort to give them the best product for the application. If they need digital with pressure sensors and special software for analytics to work on the protocols such as HART, Fieldbus and Profibus, we have a solution for them, but if their application does not require a digital solution, we have reliable analog options as well,” said Wayne. “We narrow it down to the best solution for the customer, because we want to make sure the customer is satisfied. We are not just in it to make bigger sales or keep shareholders happy, because we answer to the customer, not a distant board. We go right to the heart of taking care of the customer. Analog sales are growing, and digital requirements are growing, and we have the products to meet both of those growing needs.”

The latest in positioner technology is available in the D400 and D500 digital series valve positioners. These micro-processor-based products are available with a very extensive list of features and benefits. Nema 4X is standard and IS and EX products are available in the D400 model. The D500 offers advanced diagnostics, SIL II approvals and emergency shut down options. VAC stocks these products with HART communication and a variety of accessories and mounting kits.

Product testing is performed at all points in the process—from design prototyping to component testing, to assembly and to individual calibration testing. Each unit is tested to ensure a customer receives exactly what fits their application need.

In addition, special requests are welcomed and encouraged as the team thrives on the opportunity to help customers with any application need. VAC also offers mounting kits in order to provide a full package for their customer. With the ability to mount their positioners to almost any valve package available on the market, VAC’s retrofit program has become a significant portion of the business.

Responsive Service Philosophy

Carrying strong inventory allows the company to be proactive in delivering speed-of-service and is an important aspect of the company’s responsive service philosophy. The company knows that their customers have many choices, and they work “smart” to make their choice VAC products. VAC’s simple straightforward approach to their product carries over to how they work with customers and their employees.

“We try to be the easiest partner that our vendors deal with. That means that they get answers when they need them, product shipped on time, accurate shipments and that all stems back to working with a team with a common goal of working for our customers,” said Randy. “Those are qualities that have not changed since the beginning, has continued to this day and will continue on forever.”

“Our key to success is to hire exceptional people, give them the tools and knowledge they need to be successful. We focus on how to treat customers with respect and how to be fair and balanced. We answer questions within hours, sometimes minutes and we ship most of our orders within 24 hours. Service, integrity, respect and a positive workplace environment, are at the core of our day-to-day business,” Wayne said.

Selling through stocking distributors and OEM customers in Canada, North, Central, and South America, VAC relies heavily on the strength and commitment of their channel distribution partners. VAC has a network of stocking distributors that support and serve their local markets. Additional factory inventory is maintained in their Distribution Center in Chelsea (Birmingham), Alabama and locations in Europe, where complete assemblies and spare parts are always “a day away”.

“We have put a lot of effort over the years into locating and training committed distribution partners. As a small company, you cannot force things down your distribution channel. We have built relationships by not only having a high-quality products, but by treating our distribution partners with respect, proving ourselves through consistency and making ourselves stand out by having good people,” said Wayne. “It does not matter who answers the phone, everyone is treated like part of the team and that is a message that we have consistently passed on to customers and distribution partners for 20 years.”

Reliability is always an important goal for the process industry and VAC recognizes the importance that after sales technical support, training and education can mean to their customers. VAC also offers two-year warranties on analog and one-year warranties on digital products. The company will inspect any defective products, make the necessary adjustments or completely replace the product under warranty.

“If even one positioner or valve fails in a plant, it can cost the operator thousands of dollars very quickly. The service during a sale and the product are important, but after-sales technical support is critical,” revealed Wayne. “When a customer needs technical support, we want to make sure we are always available, whether it is to talk them through something over the phone, cell phone photos, or if possible, use video conferencing to take a look at an issue, or if we need to have someone on-site. We realize and recognize very readily that being able to help them when they need it is one of the key aspects of making sure the customer remains a customer. You can sell them a good product at a good price, but you can lose a customer if you neglect to support them.” Good training, equates to product knowledge which builds confidence when needed in the field.

On to the Next 20 Years

In 2020, businesses found ways to pivot their processes and adapt to new ways of interacting with customers as the global pandemic altered the way the world does business. When it became harder for VAC to host in-person training for their customers, they implemented a new series of training videos online, as well as developed educational webinars.

“We have always offered training classes but last year, our first one was in March, and that was right before everything completely shut down. We have adapted so we are able to digitally sit down with a company one-on-one and go through all the procedures without people having to worry about traveling,” explained Randy. “Our customer relationships have always been so important, so being able to continue to work with them online has been imperative and it helps us learn how to be a better partner to the customer.”

Going forward, VAC is going to continue to focus on the important qualities that make the company unique – staying true to their core values, maintaining product and personal integrity and valuing their customers. The team is determined to preserve the unique culture that they have built over the past 20 years, by remaining independent, accessible and reliable for their customers.