There are many advantages of Valmet’s Neles NDX valve controller after installation on valve assemblies. The company has reported positive news about the North American approvals and the energy savings realized from the reduced air consumption.

Mark Buzzell, Director of Valve Controls and Actuators for North America, has worked closely with the industry for almost two decades. Buzzell shared his insights about the product’s history, development, and sustainability benefits. He also explained what it means how this one universal controller can do it all.

When was the Neles NDX developed?

MB: The first generation Neles NDX valve controller has a development history based on more than 60 years of valve controlling experience. It was released in 2016 and has a significant installed based around the world. Over the years, the valve controller has received incremental improvements. In November 2022, the more versatile, next generation version with universal performance was released. The Neles NDX 2.0 valve controller has North American Class I and Division 1, and Class I, Division 2 certifications for non-incendive and intrinsically safe installations. With these new certifications, the Neles NDX is suitable for even more applications than ever.

How did the 2.0 version valve controller come about?

MB: Technology is always advancing for digital valve controllers. Current trends are developing in Centralized Control Systems architecture. At Valmet, it is important to stay informed of process automation advancements – from bus networking technology and user interface options to hazardous and nonhazardous area requirements.

Since the release of the original Neles NDX valve controller, it has had significant enhancements with the Local User Interface (LUI), electronics module, enclosure design, diagnostics, and valve speed options. Over the past 20-plus years, the goal has been to develop a single valve controller with universal valve control performance, which was achieved with the 2.0.

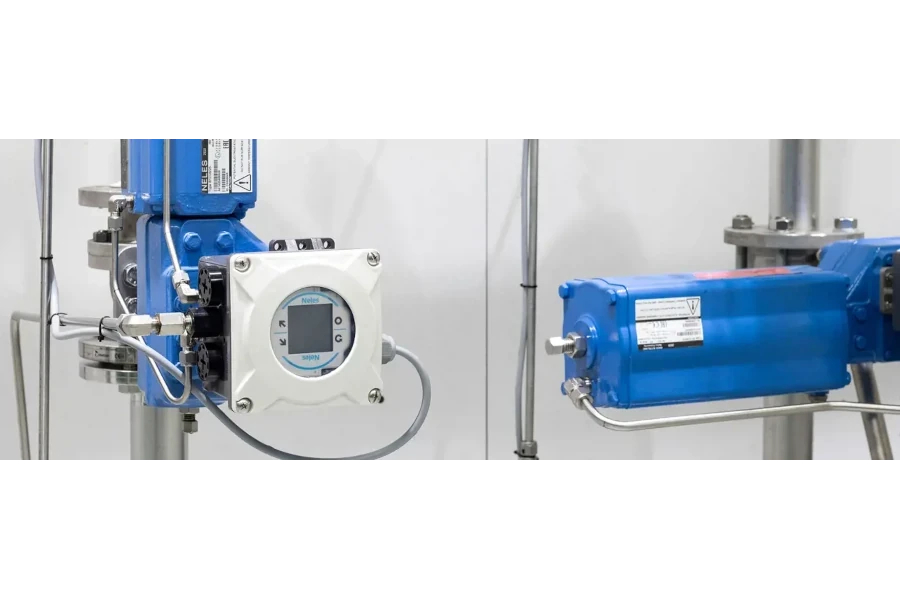

This was a considerable accomplishment designing one model that supports various sizes and types of actuators, single- or double-acting, without the need for additional instrumentation. This is the reason for the release of the Neles NDX 2.0 valve controller. This one controller can do it all.

What makes this device a universal valve controller?

In one word, versatility. This is a modular device that is easy to install and use. It mounts on practically any valve or actuator. Process plants that have standardized on the Neles NDX valve controller were able to minimize and simplify their inventory, reducing operational complexities.

It can also improve reliability. The components manage harsh environments. The exhaust adaptors protect the internals of the actuator, and the premium diagnostics are constantly evaluating the health of the valve assembly and reporting that back to the asset management system (AMS). It is easy to see how this latest generation valve controller provides a sustainable solution for accurately controlling all valves, regardless of application or industry.

Explain more about what makes installation and use easy?

Consider an installation where the valve controller mounts to a linear valve. This has traditionally been challenging and time consuming. Now it is relatively simple because the Neles NDX uses a magnet and bracket. It makes installation easy and there is no guesswork since it has an alignment tool.

The standard LUI can be accessed with the cover on. Users just follow the built-in Guide Startup. With the push of a few buttons commissioning reduces from minutes to seconds, even for first time users. This leads to improved efficiency and savings for the distributor and the end customer.

What makes a valve controller a sustainable solution?

There are many contributing factors. The ability for simple installation and easy commissioning directly translates into enhanced reliability and cost savings. The versatile “one for all” solution reduces inventory and enhances order lead times.

By ensuring customers have the right product when needed, their plant experiences more uptime. This contributes toward sustainability. Sustainability and energy savings is at the heart of Neles NDX’s pneumatics design. Imagine reducing air consumption by up to 90% while still having 10 times the air capacity? Substantial savings in air directly translate to less energy, subsequently reducing CO2 emissions.

Courtesy of Valmet.