Positioners fulfil a key role in the world of flow control, helping to ensure that control valves perform as expected. And within that world, Valve Accessories and Controls (VAC) is increasingly carving out a niche for itself as an approachable, transparent company delivering no-nonsense information, fast service, and above all reliable, cost-effective valve positioners and accessories.

By KCI Editorial

Based in Chelsea, Alabama, Valve Accessories and Controls (VAC) takes pride in its independence, its range of positioners and its open relationships with all its stakeholders. “At VAC, we thrive on being an independent player in a market that is filled with big corporate companies. Being privately owned brings real value to our customers as we can offer them products which are fully aligned to their specific applications. And as longstanding clients will confirm, we never, ever try to upsell,” states President Randy Estes.

Amplifying on this statement, he notes how new customers often reveal previous instances of being pressured into buying positioners as part of a brand integrated package rather than the best possible valve package for the application.

“Speaking frankly, they have been sold expensive positioners with features they are never going to use. We see this time and again. Our approach to doing business is the absolute opposite: we want to develop lasting relationships based on transparency and trust, where the client enjoys doing business with us.”

Supply Chain Partners

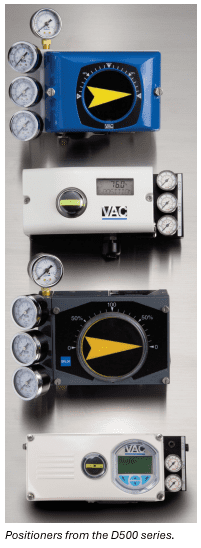

As a master distributor, VAC has built up equally solid relationships with its own sources, two well-known OEMs based in Sweden and Germany. “Our relationship with the Swedes for example extends back for more than a quarter of a century and this company has entrusted us to serve the entire Western Hemisphere with their analog positioners. Our other OEM manufactures a very wide range of digital positioner products. As we are a specialist company, we therefore create added visibility for their digital positioner range.”

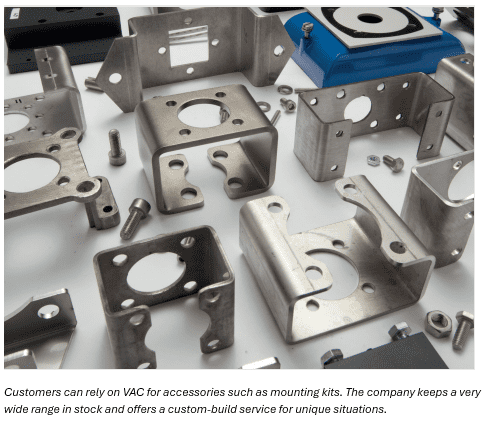

VAC’s portfolio of analog and digital positioners (see box) as well as mounting kits and related accessories are primarily made available to companies throughout the USA and beyond by a network of stocking distributors. “Our goal is to deliver top service,” states Estes. “If an end user is looking to source a new positioner to retrofit onto an installed actuated valve, he will invariably turn to his longstanding local distributor. That is why working with knowledgeable partners who stock our products locally is important to us and especially to our final end users.”

With retrofit sales accounting for around three-quarters of VAC’s business, Estes notes that orders from valve and actuator OEMs make up the remainder. “These companies purchase positioners to fit to new-build flow control systems – sometimes using VAC products instead of their own brands,” says Estes with a wry smile.

In addition to working with distributors and OEMs, Estes confirms that VAC often communicates directly with end users requesting advice or technical information. “However, VAC never makes direct sales to the end user; all commercial discussions take place via the end user’s tried and trusted distributor. As an aside, we are seeing more and more end users add our company to their approved manufacturers lists.”

Fast Deliveries

VAC has the scope to deliver large numbers of positioners to fulfil project orders. Giving an example, Estes mentions a well-known electric vehicle manufacturer that recently implemented a factory expansion project. “Increasing numbers of our positioners have been finding their way to this specific company, resulting recently in the largest single order in our history.”

This specific purchase sparked internal discussions about how best to organize day-to-day activities and streamline order fulfilment. Estes: “Large orders will clearly take time to properly box up and ship out. In many cases that will not cause problems as OEMS and distributors typically work with lead times of up to ten weeks. Nevertheless, we have been reviewing the best way to deal with these and other emerging challenges to ensure we do not lose our reputation for quick shipping. Indeed, our goal for the retrofit business has been and will continue to be to ship orders within two days.”

Analog or Digital?

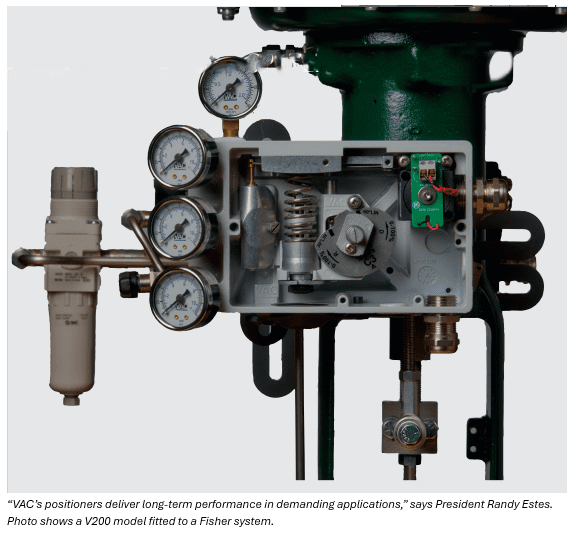

Within the connected world, many view the transition from analog to digital products as a given. However, this does not necessarily hold for positioners, explains Estes. “Since 2010, we have seen heightened interest in digital technology. Without doubt, our digital positioners benefit from handy features and can deliver real benefits. However, don’t fall into the trap of considering analog to be an antiquated technology. Our V200 analog positioner is on a par with digital positioners in terms of accuracy. Moreover, analog positioners are field repairable. So, if the end user keeps just a few spare parts in stock, he can in many cases fix problems within minutes, helping to avoid expensive plant downtimes and without the need to remove the positioner from the valve.”

Widespread Applications

Since the company was formed in 2001, VAC positioners have found their way to numerous end users for deployment in countless applications. As Estes puts it: “Our positioners end up anywhere and everywhere where a product flows and people want to control that flow. That includes wastewater processing, chemical facilities, oil & gas, mining, pulp and paper, food processing – even breweries and distilleries! Recently for example I stood on the top of a medical building where dampers have been fitted with our positioners to ensure optimal air flow.”

Estes and his colleagues are keen to further extend their market coverage. “In that light I can again refer back to sales to the automobile industry as well as companies who carry out space missions. I have personally seen new launch pads built in Texas at a rate which is frankly amazing.

Appreciating that many applications are in challenging environments, VAC offers a wide range of specifications and finishes. For example, nickel-coated bodies.

Estes: “Nickel-coating may sound expensive but is really a cost-effective solution. Such products are ideal in caustic wash down areas, in food and beverage environments, etc. Indeed, some customers select nickel-coated positioners purely for esthetic reasons.”

Another coating on offer is Tufram, which improves hardness, wear and corrosion resistance, as well as adding permanent lubricity to aluminum components. “Originally invented by NASA to make aluminum stronger, we use Tufram extensively for highly corrosive environments, such as the chlorine industry. This coating adds longevity to our positioners,” states Estes. “It is not for nothing that we offer a two-year warranty.”

Eliminate Moisture Now!

As part and parcel of VAC’s approach to the market, the company is determined to make reliable information about positioners widely available. Hence, the company website has an extensive array of support pages, including tech tips, videos, and documents. Further, staff often give live demonstrations during trade fairs, whilst longer face-to-face training sessions are regularly organized which draw in distributors, OEMs and end users, all keen for guidance on how to achieve maximum performance from positioners.

In practically all exchanges, Estes and his colleagues hammer home the message that proper precautions can help prevent unnecessary positioner failures.

“Moisture in the supply air can be a real concern and can lead to equipment malfunctions. This is why we state that the end user should always take steps to eliminate moisture in pneumatic systems, especially those located in hot, humid locations such as the south of the USA. The solution can be very simple, such as fitting a coalescing filter. And yes, we naturally have a range of suitable filters in our portfolio.”

No Nonsense

VAC’s positioners are designed for ease of installation, with end users and valve OEMs often fitting the positioners themselves. Naturally, VAC and its distribution partners are more than willing to provide advice and even to undertake all the necessary work whenever required, says Estes.

“As existing clients will confirm, we take pride in being available 24/7. If you need any kind of assistance or information, then please call and we will do our utmost to help. Thanks to the advent of video conferencing, we can often give on the spot guidance should a customer have concerns during the installation procedure, for example.”

Summing up, Estes says that he defines success not in terms of sales figures, but rather by the company’s reputation as a trustworthy partner. “We are known as a vendor that is easy to deal with, that offers great products and that provides exceptional service. Our positioners have been installed in countless demanding applications and their performance speaks for itself. We truly are a no-nonsense solution provider that puts our clients’ best interests at the heart of everything we do.