Targeting specific markets in the valve industry is challenging. The key lies in delivering proven, tested technology and promoting brand value to stay and remain competitive.

By Bob Donnelly, Vice-President of Business Development, Flo-Tite Valves & Controls

In the valve industry – where major manufacturers have strong relations with key end users and utilize automated MRP systems and valve assemblies based on long-standing specifications – the only way for new market entrants to be competitive is by introducing new valve technologies.

Not even are lower price points effective enough. Changing specifications in sophisticated MRP systems, adapting to the growing presence of Configurators, and interacting with online ordering systems all result in added time – and added costs.

Lastly, there is the challenge of getting on an approved manufacturers list (AML) at most established, larger end users.

Brand Equity

Brand equity is the value that companies build for their products, services, or systems in their respective markets. For example, a company like Apple has the highest brand equity in the world.

Marketing is a battle for the consumer’s interest concerning a product and a company’s key objective is to capture and retain that interest. If it is successful with a strong position in the target market, then the company can command a premium price. It can also possibly eliminate any serious competition and have a guaranteed stream of revenue for as long as that position is maintained.

The challenge for any new entrant to any market is to supply a new demand, product or system and displace it with what already exists. To do this, a company has to demonstrate that the product is either faster, better, or less expensive (or all three).

In the technical valve industry, this is challenging. A company must prove that its new valve or process control application represents a significant technical improvement over what is proven in a certain segment of the industry.

This requires test cases. These can prove that a company’s valve technology is better, more cost effective and/or is a significant improvement over existing process control operations for a specific industrial application or a generic manufacturing process.

Once established as a proven new technology, it needs to be marketed to build brand equity. This typically takes time in any mature market – especially in the valve market.

Key Examples

Discharges of harmful hazardous materials and other environmental concerns from manufacturing have become the subject of a variety of clean air regulations globally.

In any segment of the industry that has ball valves controlling the flow of processes through a network of piping during manufacturing, a primary concern is a potential leak path through valve stem seals. The repeated cycling of any ball valve over extended periods can cause fugitive emissions to escape through the valve stem packing.

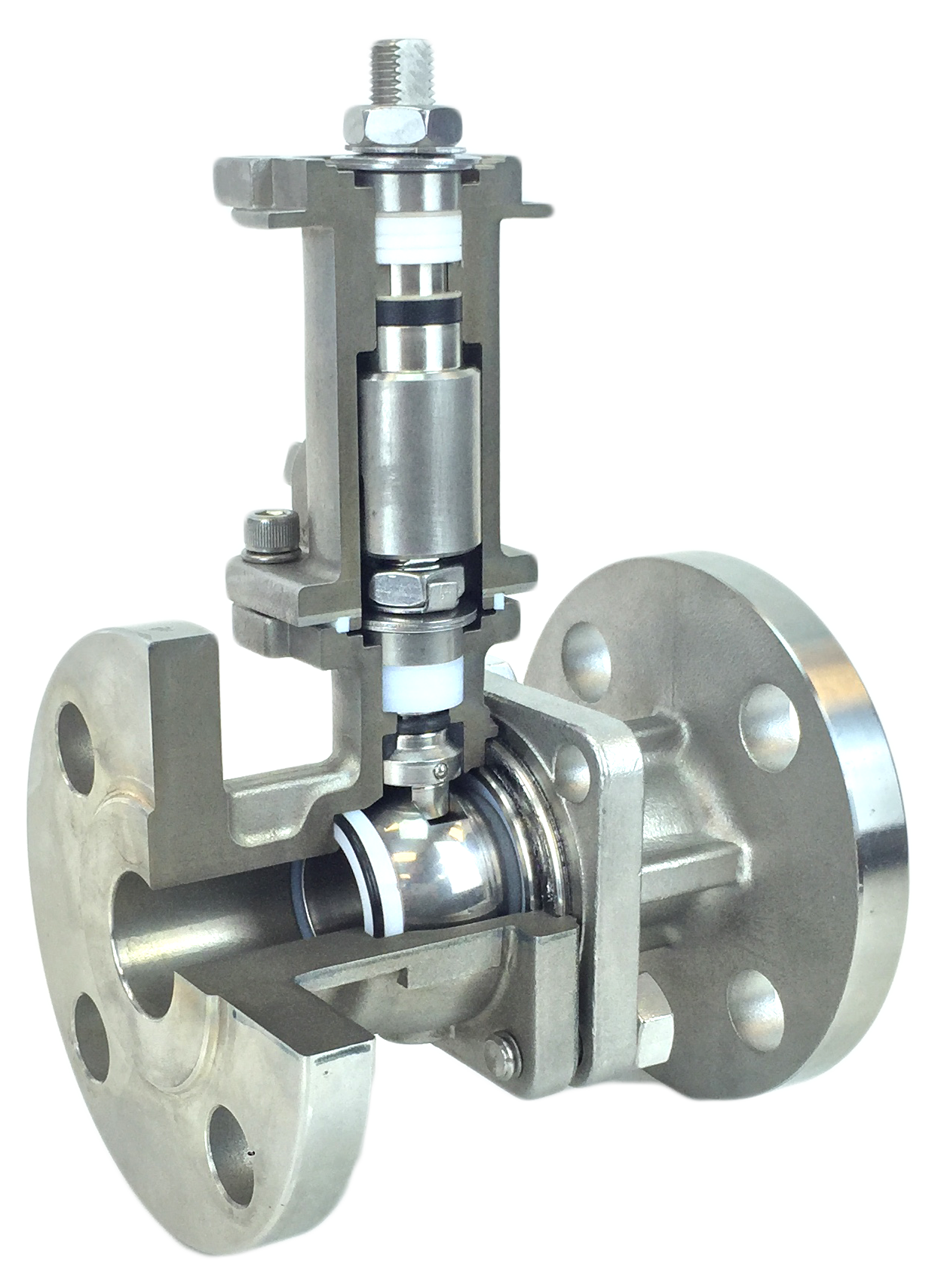

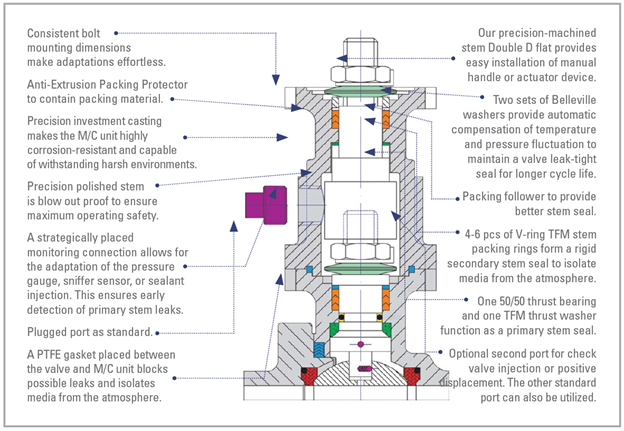

Certain valve suppliers have pioneered technological solutions for this potential problem. One is a multi-purpose, secondary media device that also serves as a monitoring system. These devices provide a secondary sealing mechanism for the valve stem.

By adding a secondary set of graphite stem packing with a live loaded design using Belleville washers, these can automatically compensate for any temperature or pressure fluctuations. As a result, it maintains a leak-proof seal and extends the life cycle of the valve. These devices also help protect valves from high-temperature media.

Considering potential plant shutdowns due to emissions of hazardous materials, the possibility of EPA fines, workers’ compensation problems – to name a few serious issues – the development of Media Containment Devices can be a significant way for a valve manufacturer to differentiate themselves from their competitors. In doing so, they can create brand equity through the development of their new valve technology.

Considering potential plant shutdowns due to emissions of hazardous materials, the possibility of EPA fines, workers’ compensation problems – to name a few serious issues – the development of Media Containment Devices can be a significant way for a valve manufacturer to differentiate themselves from their competitors. In doing so, they can create brand equity through the development of their new valve technology.

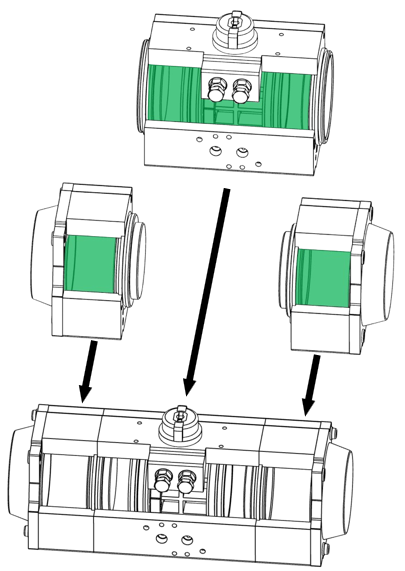

When it comes to technological design developments, one opportunity to increase brand equity for pneumatic actuators is to eliminate the need to maintain both double acting and spring return/fail safe actuators. This can be accomplished by developing a “spring-less” rack and pinion actuator, which performs the same function as a “spring return/fail safe” design.

The concept is to develop a larger set of end caps with integral air reservoirs that contain enough air to close the actuator as would the torque of the springs in a spring return/fail safe actuator. This way, the cost and maintenance of two sets of actuators are eliminated given all the possible spring configurations.

Additionally, the “spring-less” design is a “closed-loop” design prohibiting any contaminated air from entering the actuator, which is the case with spring return/fail safe designs. These are “open loop,” which flows contaminated air that can cause microbial contamination.

These are a just few examples about how to use valve technology as an ideal tool to build brand equity in the valve industry.