Thermoplastic valves and pipes have increased in popularity within water, wastewater, and chemical treatment spaces. While metallic valves have existed for centuries, engineered thermoplastic valves are only about 50 years old. In fact, thermoplastic valves and piping have seen strong growth in implementation over the last few decades. Valves made from polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), polypropylene (PP), and polyvinylidene fluoride (PVDF) are now used every day in numerous municipal and industrial applications.

By Shane McDaniel, Business Development Manager – Asahi/America.

Thermoplastic materials, like PVC and CPVC, are both internally and externally inherently immune from corrosion. They do not rust, scale, or leach into the flowing media. When compared to metallic valves, thermoplastic valves offer unparalleled benefits such as corrosion and chemical resistance, lightweight factors, and low material and installation costs. The temperature and pressure ranges for thermoplastic valves meet approximately 70 percent of all industrial valve application requirements. Therefore, they can be considered for most applications where metallic valves are typically specified. When designing or replacing a system, understanding the benefits and limitations of thermoplastic valves in comparison to metallic valves can aid in lower overall repair costs and limited shutdown time.

Quality

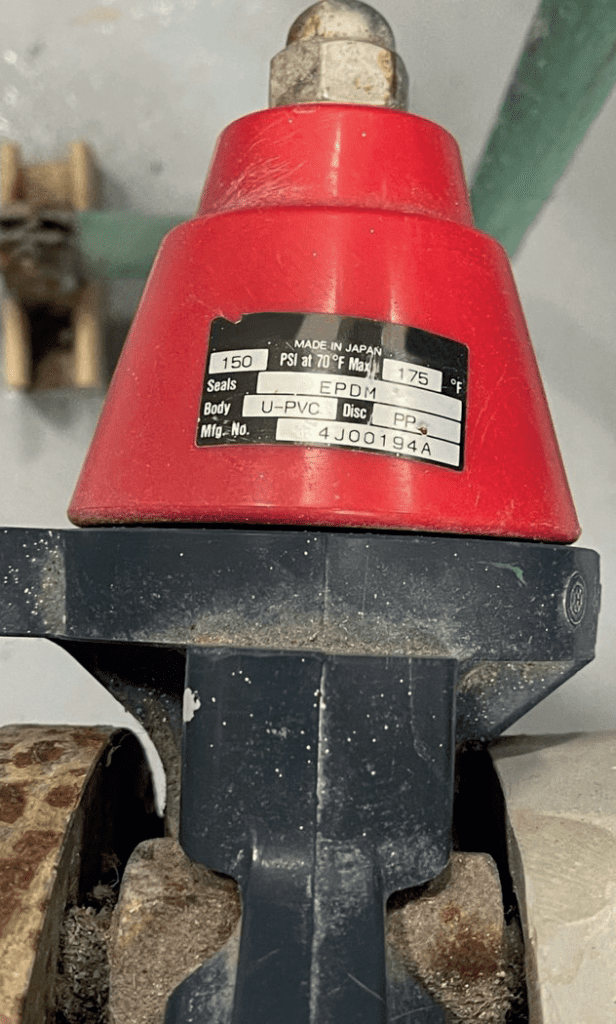

Thermoplastic butterfly valves offer a variety of benefits for ease of installation and function. High-quality valves are made with high density resins and utilize manufacturing techniques that ensure durability and reliability. Injection molded bodies can contribute to performance over welded or glued parts. Closing members like discs or balls should be overmolded or have a single piece design to limit potential failure points. Thermoplastics should also be vetted for their quality control, such as cycle and hydrostatic testing methods. A quality manufacturer will share results on maximum working pressure testing, as well as pulsation and leakage testing. Wetted materials like seals and discs should be the only components in contact with the flowing media, as well as also contributing to working life and reliability of the valve.

Cost

Cost is often the driving force behind repair and design decisions. However there are a variety of other factors to consider. The chemical or media temperature and pressure in the system should influence the decision made by the engineer or specifier in conjunction with cost constraints. In many cases, initial investment cost is not the sole factor for consideration. While the purchase price is important, lifecycle management and total cost of ownership (long-term value that addresses the performance and operating costs over the valve lifespan) should also be considered. Increased performance in both installation and maintenance ensures less unplanned downtime and consequently ensures profitability. If properly installed and maintained, some thermoplastic valves provide decades of service life without issues and result in a low overall lifetime cost. The weight of a valve must also be considered relative to overall costs. For medium to larger bore-sized butterfly valves, it may be more economical and efficient to ship thermoplastic valves over metal body valves. This is due to significant weight differences.

Installation

Thermoplastic valve installations have both advantages and limitations. Thermoplastic valves are considerably lighter, some by up to 40%, when compared to their metallic counterparts. This is especially relevant when comparing larger bore sized butterfly valves.

A typical metal 10-inch wafer style butterfly valve can weigh more than 85 pounds, not including any actuation, while a CPVC equivalent is roughly 55 pounds. This weight benefit contributes to overall installation cost due to, reduced mechanical strain and the need for less support structure. The weight savings are also seen in the overall project budget with reduced freight costs.

Another important consideration when installing thermoplastic valves are the face-to-face dimensions. Due to differences in design requirements, as well as a lack of universal standards specific to thermoplastics, face-to-face dimensions for thermoplastic valves can differ from metallic valves, often even between manufacturers. Thermoplastic valves serve well in both metal and thermoplastic piping systems. However, retrofitting thermoplastic valves to metal piping may result in challenges with a required change to accommodate the increased face-to-face dimensions. Some manufactures provide products that conform to ISO 5752 short pattern face-to-face dimensions, though these options can be limited. This allows the user to replace a metal valve with a thermoplastic option that conforms to the same standard.

Due to their quick sealing, lower torque requirements and high recovery design, thermoplastic butterfly valves perform well in low pressure drop service applications. Like any control application, specifiers and engineers are reminded to perform proper flow calculations to avoid cavitation and choked flow conditions. Butterfly valves are available with a variety of disc designs that impact flow characteristics, Cv, and permanent pressure loss in a variety of ways. Engineers should work with manufactures to ensure the pressure drop and Cv for each valve aligns with their process requirements. Under-sizing or oversizing a butterfly valve can induce excessive wear and tear on the valve. This may negatively affect process stability and considerably shorten lifespan. A quality butterfly valve in control applications is designed and constructed to ensure both containment of the flowing media and limit the exposure to corrosive materials. Thermoplastics valves are strategically designed so their wetted parts are limited to plastic material, compared to metal parts that might corrode over time.

Material Selection

Material section is critical in assessing a thermoplastic valve over metallic options, especially for body and disc materials. The temperature range for molded thermoplastic valves range from -40° F to 300° F with pressure capabilities up to 230psi. PVC and CPVC valves are most used in industrial applications as those materials are capable of handling most acids, strong alkalis, fats, and oils. Their relatively low cost and the simplicity of installation make those materials a popular choice. PP is a member of the olefin family and has excellent chemical resistance to acids, strong alkalis, and solvents. It handles lower temperatures well but faces limitations with chlorinated hydrocarbons and other media. The costs of PP valves are similar to CPVC; PP is often used as a disc material.

PVDF is the most popular resin used for chemical and high purity applications. PVDF has excellent abrasion resistance and dielectric properties. It also has a temperature range of -40° F to 250° F. The inclusion of fluoride creates an extremely reliable bond within the other molecules in the plastic. This gives the polymer excellent chemical resistance to strong acids, organic solvents, weak alkalis and strong oxidation agents. This reliable fluoride bond is also able to resist breaking apart in the presence of a wide range of chemicals. This results in an ideal material for critical applications where the leaching of unwanted molecules can cause disastrous effects within the system. This absence of contaminants is another reason why PVDF is commonly utilized for semiconductor and pharmaceutical applications where ultra-pure water and chemically pure fluids are used.

Ethylene chlorotrifluoroethylene (ECTFE) and perfluoro alkoxy (PFA) are the two additional fluoropolymers that can handle pH from 1 – 14. ECTFE and PFA perform well where expensive metals (titanium, alloy 20, 316/304L stainless steel, or lined steel) do not. Both are used for high concentrations of acids, such as 98.3% sulfuric acid, and can be used with great success in highly oxidative applications like chlorine gas, ozone and chlorine dioxide. ECTFE and PFA are also suitable for solvents and/or high pH applications at elevated temperatures. These materials are a typically higher investment cost. However, the process requirements often offset this expense and are typically reserved for critical applications.

Soft parts, such as disc seal and seat material, are just as important as the disc and body. Ethylene propylene diene monomer (EPDM) and fluro elastomer (FKM) or Viton® are the most common seat and seal materials used as they can both handle temperatures equal to or greater than PVC and CPVC. However, FKM may become difficult to operate at temperatures below 23° F. Other options include nitrile, Hypalon, and PTFE, all of which offer varying degrees of chemical resistance, temperature ranges, abrasion resistance, and sealing performance. Most reputable thermoplastic valve manufacturers design their valves to meet the ANSI Class VI shutoff standards (bubble-tight). The most critical component to thermoplastic valve selection is ensuring the body, disc, and seat materials are compatible with the application pressure, temperature and chemical resistance factors.

Actuation

Like their metal counterparts, thermoplastic butterfly valves can be actuated with a variety of accessories. When used in isolation applications, both metallic and thermoplastic butterfly valves are typically lever operated. Due to lower torque requirements, overall operation may be easier on operations and maintenance personnel. A reputable manufacturer will provide a lever handle of similar materials that fit the application requirements and include features such as notched handles for positive position indication and locking capability for OSHA standard lock-out-tag-out requirements. Larger bore valves, typically above 8 to 10 inches, utilize a gearbox and handwheel. It must be noted that the gearbox construction should be considered with the same requirements for corrosion resistance and performance. The potential for external corrosion from vapors also exists. A solid-body thermoplastic valve has the same chemical resistance on the outside where a coated metal valve may not. Coatings are also commonly scratched and chipped from flanged bolts and tightening during installation. Like metallic valves, thermoplastic valves can be outfitted with accessories like chain wheel operators, stem extensions, tandem linkages, and other common valve accessories.

Butterfly valves in control applications can be automated with a variety of pneumatic and electric actuator options.

The overall control scheme and system construction should be considered when specifying the actuator for your application. The comparison between metallic valves and thermoplastics is minimal; however, like the face-to-face dimensions, not all manufacturers of thermoplastic butterfly valves utilize the same mounting dimensions. Yet reputable manufacturers often construct their valves with an ISO 5211 or similar mounting pad standard. Using a valve without this type of standard may negatively contribute to cost and complexity. For standard on/off or open/close applications, a pneumatic actuator is commonly used. Here, a rack and pinion design are most used. Spring return failsafe is often a consideration in these applications as well, ensuring proper control of flow in the event of a failure. Electric actuation is an option as well in thermoplastics, especially in modulating control, and areas where compressed instrument air is limited. Electric actuators often integrate the capability of control, indication, and failsafe into a single package that simplifies installation and sourcing. Pneumatic accessories like switches and positioners require more engineering and design considerations. Sourcing thermoplastic butterfly valves from a supplier that offers quality accessories and automation contributes to project efficiency and overall cost containment.

Thermoplastic butterfly valves, while relatively new in the industrial control space, are proficient in several applications and provide benefits that can positively influence design, operation, and overall profitability.

Case Study: Zoo Life Support System

A western United States zoo needed a dependable, long-lasting solution for their newly constructed life support system for an animal exhibit. Life support systems can include animal water intake lines, disinfectant lines, water temperature control, and tank flow control. These are critical systems that directly affect animal life and well-being. Without proper maintenance or when constructed with low quality components, there can be adverse effects to the animals’ lives. Even slight variations in the water quality or system could have devastating effects in the animals’ environment. The life support system constructed at this western U.S. zoo required heavy amounts of salt water to run through the valve and piping system. The harsh salinity of the water running through the piping system meant a potential for corrosion and abrasion on the valves, which could result in costly and timely repairs if the valves were to fail. As animals depend on these systems to live, there is minimal time available for maintenance or repairs. As a solution, some PVC/PVC/EPDM butterfly valves with titanium stem, handwheel operators, and plastic levers were installed. These thermoplastic butterfly valves were installed in the mid-90s and at last inspection, after twenty-five years of service, the zoo was happy to report no major issues or shutdowns.