In today’s regulatory environment, any type of leakage causes a variety of fugitive emissions liabilities. We outline one of the fundamental valve sealing processes for ensured safety and compliance.

By Bob Donnelly – Vice President of Business Development – Flo-Tite Valves & Controls

Valve packing is critical to flow control performance. It seals the gap between the valve stem and stuffing box so fluid cannot escape. The packing must maintain this seal while the stem moves through multiple cycles, temperature changes, and pressure variations. Even though the packing is only a minor cost of a valve, it has a significant impact on safety, reliability, and compliance.

If there is a defect in the packing, the result in any process control operation can be serious. Product loss increases operating costs and leaks can create a plethora of safety issues. Additionally, extra friction can result in stem wear making it difficult to operate the valve. Obviously, in today’s regulatory environment, any type of leakage causes a variety of fugitive emissions liabilities. To avoid these issues, old-style flax and hemp packing has been replaced by new fibers that can manage extreme heat, corrosive chemicals, and cycling stress. They also meet current emission requirements.

For example, graphite packing is now used in high temperature steam valves and Polytetrafluoroethylene (PTFE) is the preferred material for chemical services since it is resistant to harsh chemicals and provides very low friction. Carbon fibers support high cycle services, especially with control valves that stroke frequently.

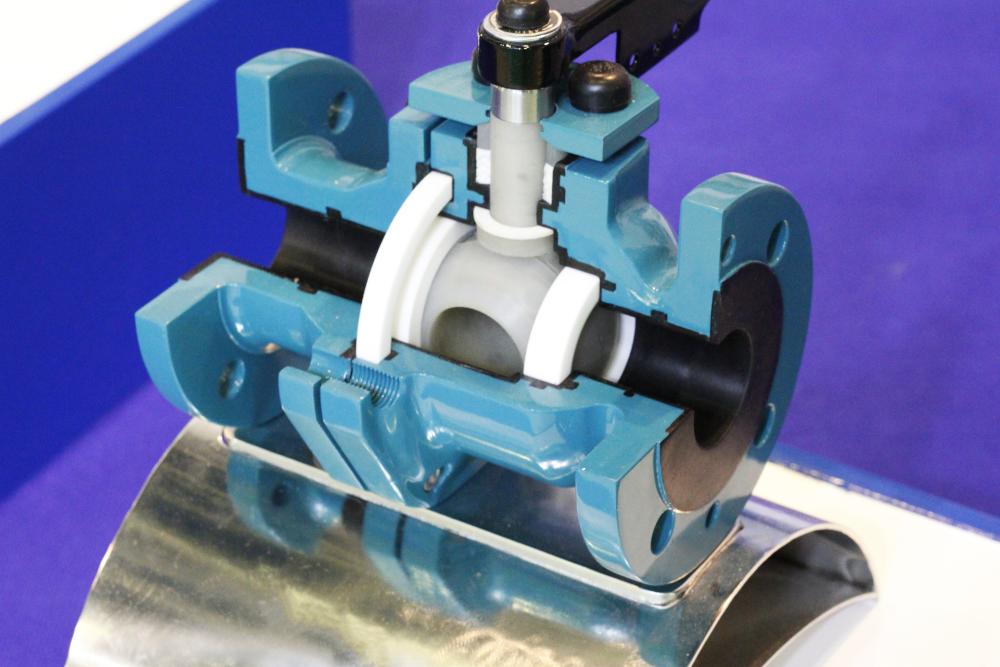

For these applications, packing is now manufactured from hybrid braids that combine properties to balance sealing pressure, durability, and ease of operation. The unique feature of the fibers is that they are “braided” under controlled tension to maintain uniformed density. The packing is cut into rings and stacked, forming a sealing set that interacts mechanically with the valve stem and stuffing box.

Today’s valve packing is also quite different from the old rope and lubricant technique that formed more of an engineered sealing element. Packing seals now effectively convert axial forces into radial pressure.

So, when the gland follower is tightened, it compresses the packing rings downward. This compression forces the packing outward against the valve stem and stuffing wall. The radial pressure has to be high enough to stop any fluid leakage, yet low enough so that the valve stem can still move freely.

This balance is critical to performance —too little pressure leads to leakage, and too much pressure increases friction. As a result, it causes stem scoring and can prevent actuators from seating or stroking the valve correctly. It is important to note that once the packing is installed, it should be cycled and allowed to settle properly. This initial step helps form a uniform sealing surface.

If done correctly, only small adjustments will be required to maintain performance. To ensure reliable performance, packing rings must be cut to fit cleanly around the stem. Rings that are too long will bunch up and distort under pressure. Rings that are too short will leave a gap that can cause leakage. The most effective way to cut rings is on a mandrel that matches the stem, which ensures the correct length.

Simple inspections of the stem and stuffing box surfaces must be done. A scratched stem can create a direct leak path, which any packing cannot compensate for — a corroded stuffing box wall will produce uneven compression.

New testing requirements like API 622 tests the packing under thermal and mechanical cycling and API 624 evaluates the performance of valves assembled with modern qualified packing. These standards not only changed the packing materials, but also the expectations around the stem finish, valve design tolerances, gland follower flatness, and load control procedures.

Additionally, with many other valve configurations, proper training, testing, and accurate installation manuals are essential to avoid costly consequences of hazardous emissions, fires, and physical harm to employees, which the financial liabilities can be substantial.