The Russia-Ukraine conflict has exacerbated logistical disruptions caused by the rapid spread of Omicron variants from late 2021. China’s zero-COVID strategy to fight against the pandemic have extended the shortage of raw materials in the global market. Russia’s gas supply cuts to Europe will add more challenges to manufacturers in Germany and Italy. The valves industry is enduring longer lead times, growing backlogs, and a rise in logistics, transportation, and freight costs. Original equipment manufacturers (OEMs) are trying to source supply from a wider array of countries to ease resource constrains.

By Yi Tan, Principal Research Analyst – S&P Global, formerly IHS Markit

The Russia-Ukraine war has hit the global supply chain, interrupting production and sales activities in Russia. At present, prices and availability in valve manufacturers’ procurement markets are highly unpredictable. Elsewhere in mainland China, the Beijing government is adopting a ‘zero-COVID’ strategy against the rapid spread of the new Omicron variant. Extreme measures to suppress the virus for a prolonged period have affected the availability of raw materials in the global market, leading to some damages to suppliers’ businesses. The increase in gas supply cuts by Russia to Europe, particularly Germany and Italy, could affect manufacturers’ ability to produce valves at any plants this winter.

Major Manufacturing Sites

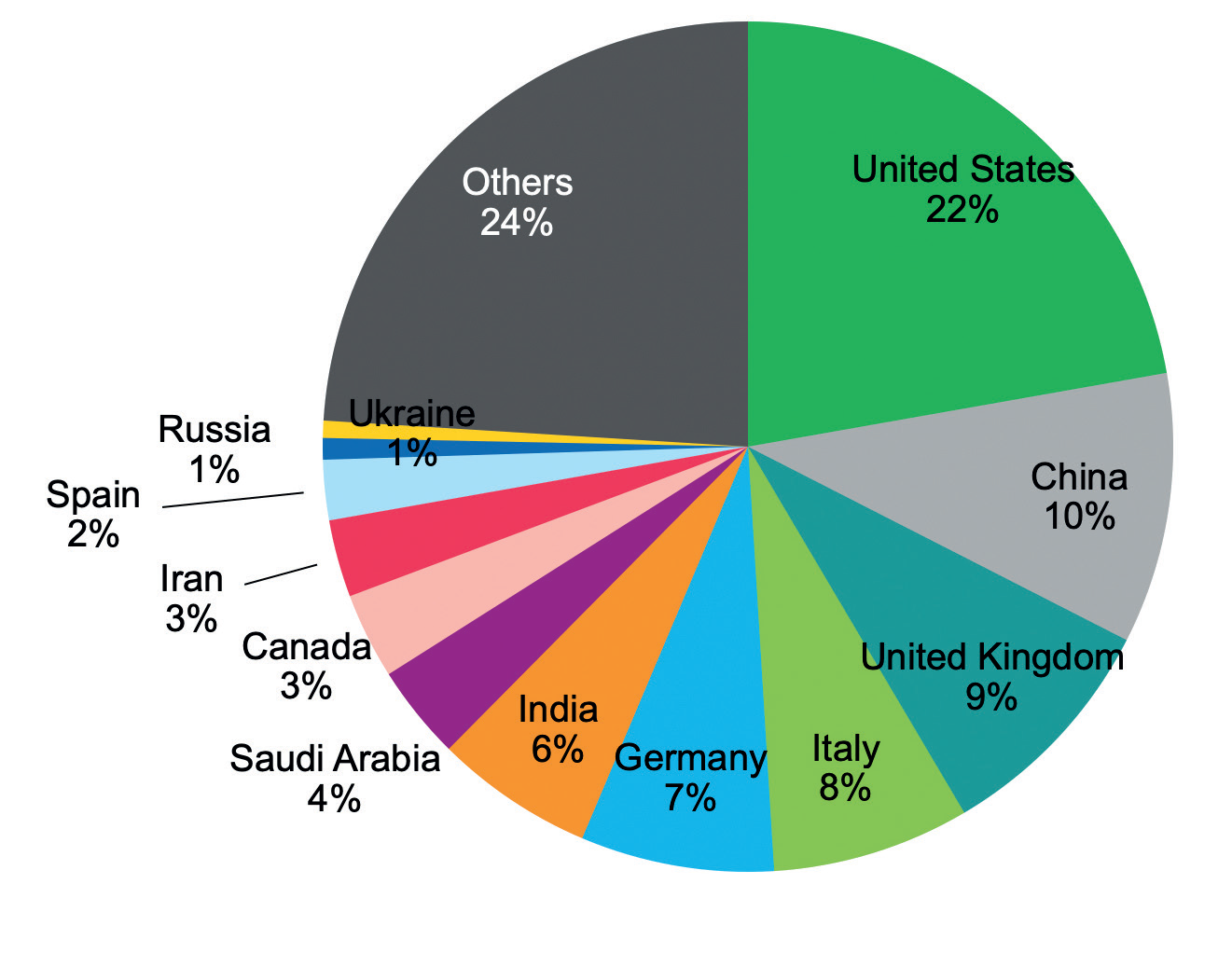

Some geopolitical uncertainties have emerged from several global flashpoints. Manufacturing in mainland China, Russia, and Ukraine has suffered the most from supply chain disruptions since early 2022. The three countries combined account for 12% of global production facilities, with China alone holding a share of 10%.

More than half of Russian oil & gas valves demand was met by imports because of limited local capability. Moscow-headquartered OMK, Penza-based PTPA and Penza Valve Plant, and Ufa-based KB MASHENERGOPROEKT are the key Russian valves manufacturers, focusing on the onshore pipelines market. Emerson, Flowserve, and IMI, the major international valves manufacturers, supply products and services through their local subsidiaries in Russia, where the German Samson and Finnish Valmet (former Neles) operate regional service and sales fa cilities. Böhmer Valve (US) and AMPO POYAM VALVES (Spanish) serve Russian clients, but their regional production and service facilities are based in Kazakhstan.

Ukraine represents 2% of valve plants and 1% of supply facilities in Europe. Hydrosila, Promarmatura, and UKSPAR are the key local manufacturing companies. Hydrosila has increased the volume of deliveries from its office in Wroclaw, Poland, to overcome logistics issues caused by the Russia-Ukraine war. ARMAPRIME, Ksimio Projects, RETUS, and SPE SYSTEMA-A are the key Ukrainian wholesalers serving the oil and gas market. Other suppliers such as ABO valve, Mokveld, SchuF, and Weatherford have offices and/or service facilities in Sumy, Kyiv, or Poltava. These firms mainly serve the pipelines market in the Commonwealth of Independent States (CIS) and Eastern Europe.

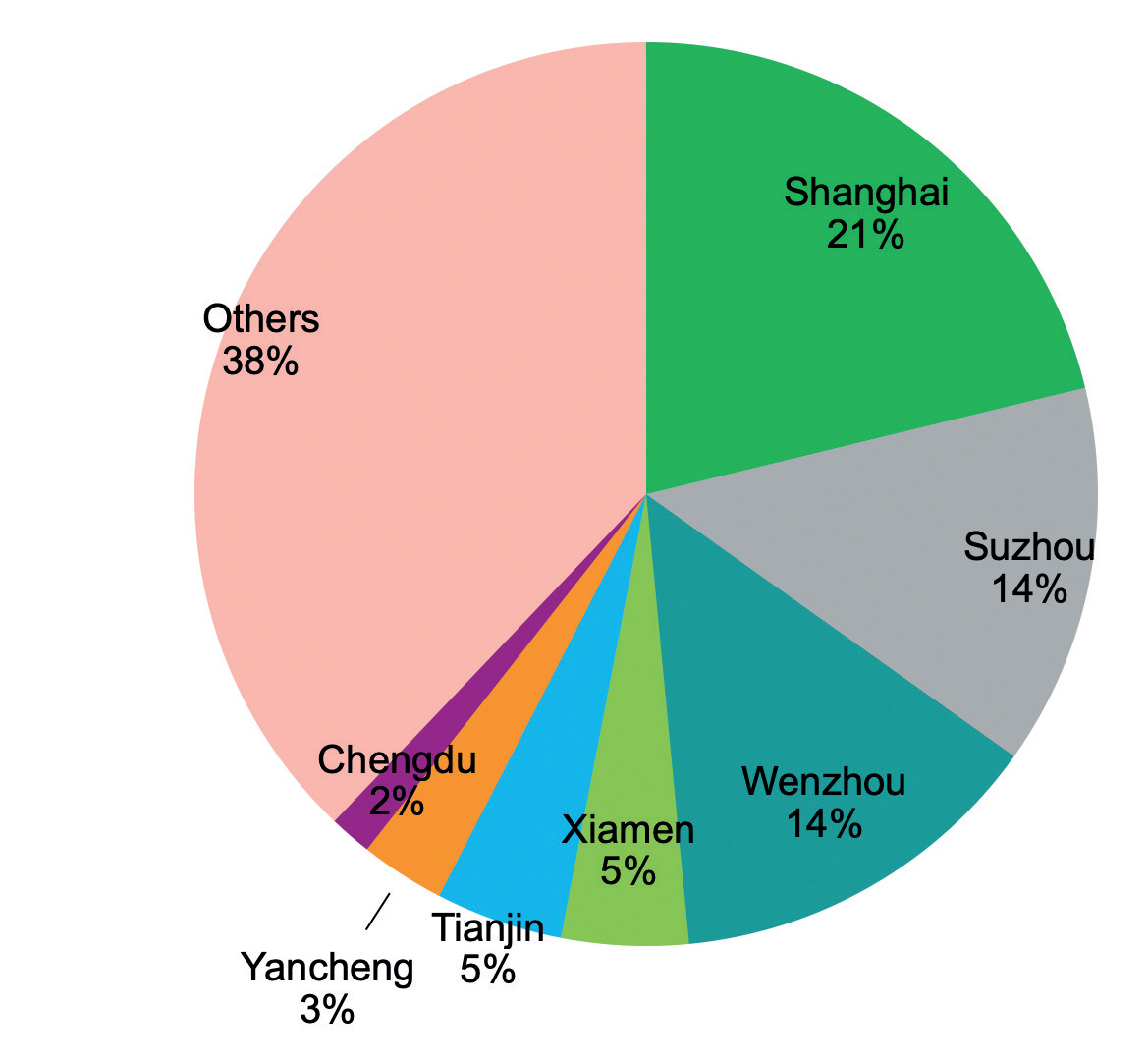

Elsewhere in mainland China, there are more than 60 valve plants serving the oil and gas market and half of the Chinese production facilities are in Shanghai, Suzhou, and Wenzhou. The Beijing government’s zero-COVID policy has led to repeated lockdowns in the country’s manufacturing hubs and major ports.

Shanghai, was fully or partially shut down in April 2022, when many plants had to cease operations, allowing employees to stay home. Re-opening began in late May and full operations commenced in early June. In September, Chengdu, another city manufacturing valves, was partially locked down. Following these disruptions, the average lost-production period for plants based in Shanghai and Chengdu should exceed 30 days in 2022.

Valves—Global Manufacturing Facilities

Valves—Production Facilities In Mainland China, By Location

Conflict Aftermath

Demand

The Russia-Ukraine conflict have stimulated demand growth in regions such as Asia Pacific and Europe. In February 2022, Gazprom’s Soyuz Vostok gas pipeline project entered the design stage for the construction of main gas pipelines in Mongolia for supplying gas to mainland China, generating potential orders for onshore pipeline valves.

In Europe, the Western sanctions against Russia boosted the region’s investments as Europe needs to find alternative energy resources to replace Russian supply. Germany will build two LNG terminals (USD 69 million) in Brunsbüttel and Wilhelmshaven in the German Bundestag and is planning to invest US D2.5 billion in four FLNG terminals. Italy has placed orders for two floating storage regasification units (FSRUs) to boost its energy security. In order to wean itself off Russian energy imports, Germany and Italy are also pushing for a faster rollout of renewables. These developments will bolster strong demand growth for valves in the LNG and renewable markets.

Buyers

Orders from Russian buyers have been pushed back. Novatek, for instance, has delayed the launch of its third LNG project in the Russian Arctic, known as Obskiy LNG to 2025, instead of 2023, originally scheduled. The sanction of associated LNG valves should be later than initially planned.

International buyers have started to cancel the orders for Russian valves or terminate the contracts relating to their businesses in Russia. The perspective projects with international investments are facing high uncertainties. Novatek’s former partners TotalEnergies and Mitsui have already written off their investments in the Arctic LNG 2 project located in the Gydan Peninsula, West Siberia. In June 2022, TotalEnergies also agreed to transfer the remaining 20% interest that it held in the Kharyaga oilfield to Zarubezhneft. Its partner, Equinor, quitted the project earlier this year. The shifts in investment resources will bring a downside outlook in contract sanctions for valves.

Buyers in Russia may have to postpone valve deliveries. AMPO Poyam Valves started in 2021 producing more than 20,000 engineered valves for the Arctic LNG 2 project, which might be postponed by Novatek as the operator will have to find alternatives to suppliers and investors that have been cut off by the wave of international sanctions. The emerging complications are likely to defer schedules for deliveries.

Raw Materials And Energy Supply

Russia’s aggressive operations in Ukraine have hit the iron and steel supplies from both countries, which are the major producing nations, and caused record-high prices for steel, nickel, and stainless steel in second quarter 2022. Prices are coming down from May as inventories build up and buying activity slows. Meanwhile, inflations in fuel and natural gas prices and the impact on electricity markets globally pose risks to both production and demand for valves over the near term, especially in Europe.

Logistical problems also arose as there are difficulties transporting products from Ukraine to European countries with mines reportedly having been laid on roads and with Russian warships blocking the Black Sea. Steel production has been disrupted owing to the downtime of other plants in the supply chain. While most Ukrainian steel plants operate with a reduced utilization, buyers from other regions such as Europe and the Middle East are looking at Indian steel as a replacement for Russian or Ukrainian steel. Finding suitable replacements for alternative materials and parts will take time.

Valve Production And Supply

Plant utilization has declined since February 2022, especially at the facilities based in Russia. Excessive capacities arose in Russia are unavailable for work outside the country. In Ukraine, although production at some valve plants in the war-zone areas has been suspended, local production and spare labor capacities cannot be transferred to other regions/countries.

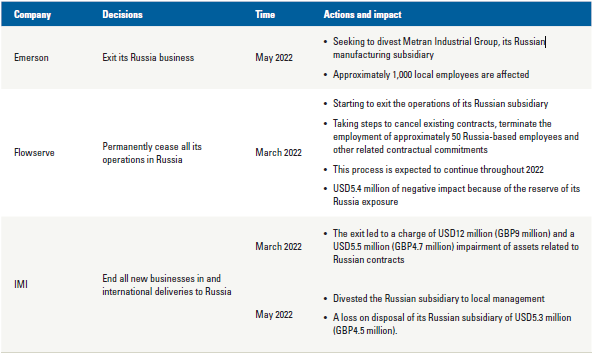

Valves imported to Russia have also slumped owing to suppliers’ terminations of operations or cancellations of valve contracts for their businesses in Russia. Major valve manufacturers such as Emerson, Flowserve, and IMI decided to exit Russia and started to lay off their Russian employees in March. Additional costs arise for suppliers to exit

the operations of Russian subsidiaries because of the financial exposures to the contracts that have or are anticipated to be cancelled.

The war in Ukraine has affected the supply of valves to some CIS or European countries but the adverse impact on the global valve production is limited. This is because plants in Russia and Ukraine only represent 2% of global capacity and mainly serve the local and regional markets. Manufacturers, especially those with a global presence, do not expect that incremental effects caused by the war will be material to their businesses, including any financial outcomes arising from cancellations of customer contracts and terminations of operations in Russia.

In Europe, companies are increasingly concerned about strong inflationary pressures, surging energy costs, and recession risks both domestically and globally. Manufacturers’ expectations on production output are pessimistic despite easing supply constraints in the second half of 2022.

Valves—Key Suppliers’ Response To Russia-Ukraine War

Zero-COVID in Mainland China

Extreme safety restrictions to suppress the virus for a prolonged period have hit manufacturing and shipping operations in mainland China, where manufacturers are taking the pressure from the rising cost of redundant facilities. Repeated COVID-19 outbreaks and subsequent lockdowns have also affected the availability of raw materials, spares, and parts. Supply of raw materials to the global market is tightening while lookdowns have extended transit times. On average, lead time for valves is likely to require an extension of 4–6 weeks in 2022.

Beijing aims to control the outbreaks through strict quarantines and travel restrictions. People must stay at home for isolations, affecting the availability of workforce and service labors. Employee and manufacturing costs, which have escalated because of temporary closures and work-from-home policies during the pandemic, are expected to continue affecting suppliers’ financial performance.

The long-term aspects on supply from mainland China may be better only if the country eases its strict measures of eliminating COVID cases. However, the COVID-related restrictions and rising labor costs, along with the persistent trade tensions between Washington and Beijing have driven international companies to look for alternative manufacturing sites with lower costs or undertake more production at home.

Supply Chain Implications

Import restrictions, reduced local production, and cancellations of valve contracts will lead to a shortage of supply In Russia. Apart from onshore pipelines, the availability of valves for all other oil and gas segments will be tight. Offshore projects may suffer postponements because of restricted supply of valves from international companies.

Although Russian manufacturers are seeking to gain new orders from other regions such as Asia Pacific, the Middle East, and South America, production recovery is unlikely to take place as long as the international sanctions are in place. Buyers that use Russian-made valves may find them in a stronger position when negotiating prices. Excessive capacities at international companies’ plants can be used to meet demand outside Russia.

The supply bottlenecks have emerged because of a shortage of raw materials, logistics disruptions, and delays at ports, leading to longer lead times and higher costs for valves. The war in Ukraine, along with the COVID restrictions in mainland China, has pushed global manufacturers to reduce their reliance on a single resource, spreading supply from a wider array of countries.

Suppliers have so far responded by increasing inventories in warehouses, diverting resources for production or changing suppliers to those with available resources, and redesigning products or materials required for products. Manufacturers may also pass on inflationary pressures to users of valves by increasing prices. Buyers holding long-term procurement agreements with suppliers will have limited exposures to price hikes.