Hydrogen places the highest demands on plant and system components, and compact sliding gate valves made of austenitic steels effectively control the small, light molecules precisely and quickly. As a result, they ensure reliability and safety while significantly lowering energy consumption during operation and production.

By Doug Roy – Vice President – Schubert & Salzer, Inc.

Hydrogen is developing into a key technology for energy transition in industry. Ideally, it can be generated inexpensively as well as in a climate-neutral manner using surplus electricity from renewable sources, thus it plays a major role in the replacement of fossil fuels.

Considering the small, light nature of hydrogen molecules, compact sliding gate valves cast of austenitic steels can precisely control hydrogen molecules to ensure reliability and safety. They also significantly contribute to lower energy consumption during operation and production.

However, the small size of its molecules represents a big challenge for plant and system components in process engineering, especially for valves, which are required to provide reliable function and high sealing integrity under demanding conditions.

The problem: hydrogen molecules can easily penetrate many materials and change their structure. Valves made of ferritic, martensitic, and even some high-alloy steels are susceptible to hydrogen embrittlement, which can lead to considerable damage and material failure.

Choice of Material is Decisive for Safety

One reliable solution is stop and control valves made of austenitic steels such as 1.4408 and 1.4404. These stainless steel alloys are characterised by their high resistance to corrosion. In addition, the nickel content guarantees a very robust resistance to hydrogen-induced embrittlement.

The choice of quality materials is also pertinent when it comes to seals. Common solutions such as ethylene propylene diene monomer (EPDM) or fluoroelastomer (FKM) cannot be used without restrictions in the hydrogen environment. Hydrogen diffuses easily into the molecular chains. A sudden drop in pressure can lead to an unexpected expansion from the volume of stored hydrogen and lead to the destruction of the seal.

To prevent material failure, the use of plastics should be reduced to a minimum. Where necessary, special plastics or — especially with high pressures — metallic seals made of copper are used to permanently ensure the function in the event of sharp, unexpected pressure drops.

Compact, Fast and Precise with a Long Service Life

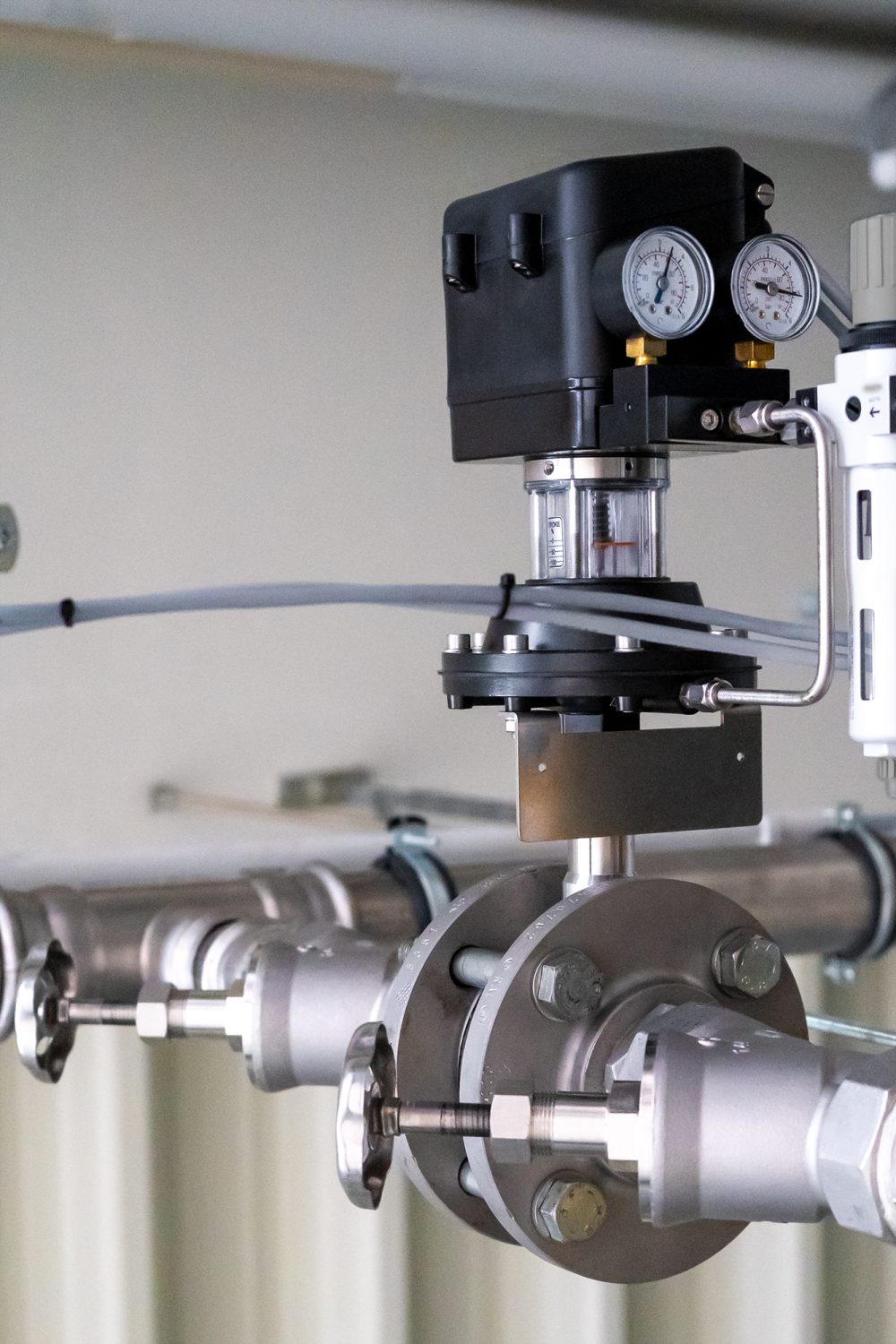

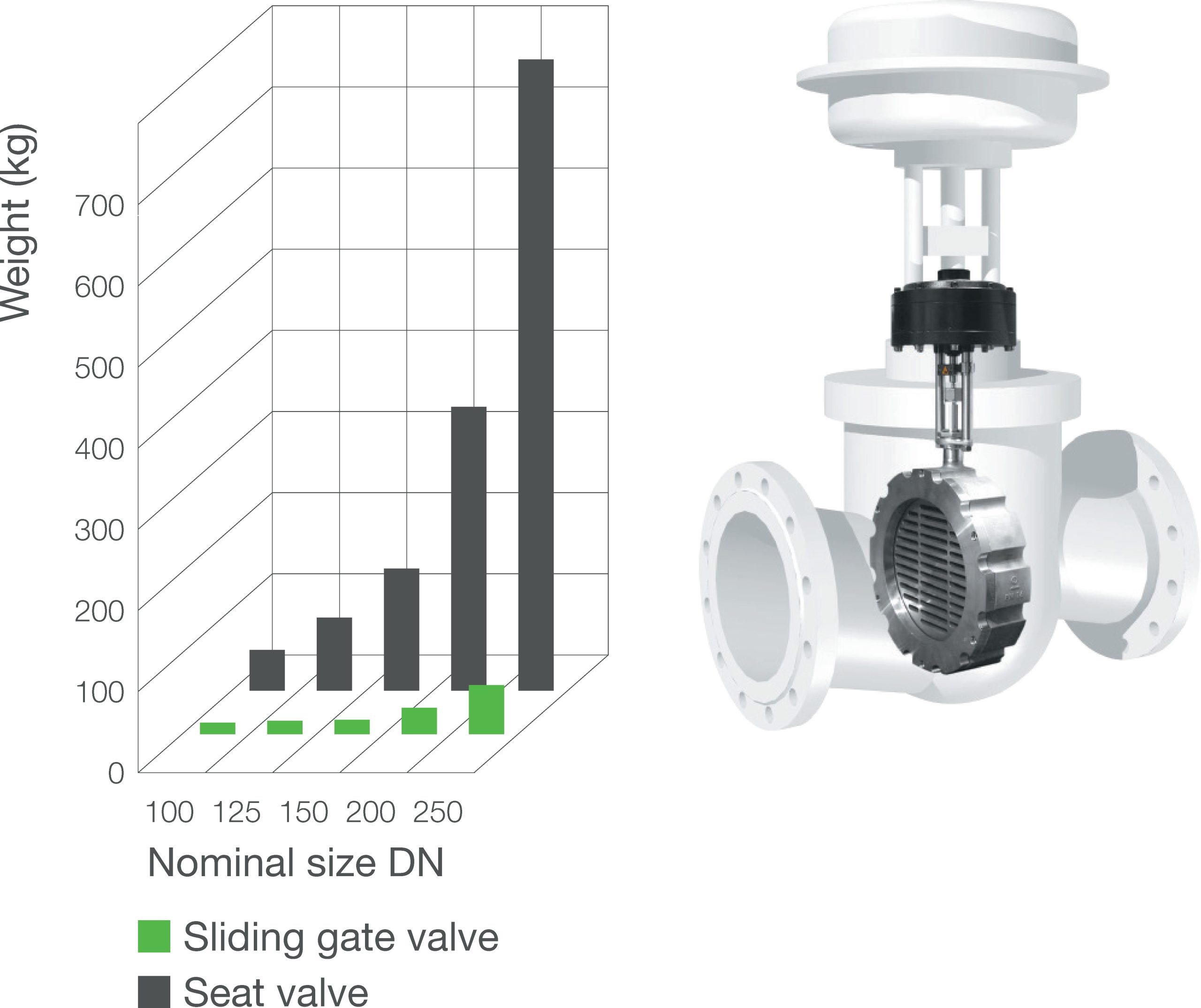

Sliding gate valves made of austenitic steels are a reliable solution for controlling hydrogen. They combine numerous advantages, especially for this application area. Their special construction principle results in an extremely compact design with a low weight, a high control speed, low-noise, as well as wear- and maintenance-free operation.

The sliding gate technology controls the flow rate in milliseconds by pushing two slotted sealing discs arranged perpendicularly to the direction of flow against each other, thus changing the flow cross section. The actuator only has to overcome the friction between the two discs resulting from the differential pressure and a short stroke from six to nine millimeters.

This makes the control valve particularly fast. As a result, the actuating force required is 90 percent lower compared to other valve designs.

Consequently, significantly smaller actuators may be used, and the consumption of control air or electrical actuation energy can be considerably reduced.

At the same time, the short strokes protect the various pneumatic actuators and the stem seal. This enables a long service life with more than a million switching cycles.

Another benefit is the savings on resources and CO2, which have positive effects on the valve’s entire life cycle — from manufacture and transport through to its operation in the plant. Service and maintenance costs are also reduced due to the compact dimensions and light weight.

Permanent Tightness Prevents Risk of Explosion

One of the most potential dangers associated with the use of hydrogen is its extremely high flammability. With four to 75 percent by volume in air, its explosion range is significantly wider than other gaseous energy sources such as propane or butane. This greatly increases the risk of explosions.

This risk is minimized using sliding gate valves as there are various designs on the market. According to the Technical Rules for Hazardous Substances (TRGS), Schubert & Salzer’s sliding gate valves are permanently leak-tight and meet the requirements of the Technical Instructions on Air Quality Controls 2021 (TA-Luft 2021) in accordance with EN ISO 15848- 1. Special versions are available to achieve body leakage rates of less than 5 x 10-⁶ mbar l/s and are therefore suitable, even for use in closed rooms.

“In hydrogen applications — whether in production, storage or transport — every component must work absolutely reliably even under demanding conditions,” says Christoph Lukasik, Head of Design and Development at Schubert & Salzer.

In addition to the performance of sliding gate valves made from high-grade austenitic steels, they serve as a critical component that is capable of delivering reliable flow control, enhanced safety, and long term operational efficiency in the hydrogen industry.