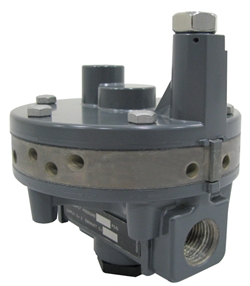

Emerson Process Management’s new Fisher® VBL booster incorporates a fixed deadband, internal soft seats and an integral bypass restriction that combine to eliminate the positioner problems typically caused by boosters without these design features.

The new booster’s enhanced performance capability proves highly important in applications where a valve positioner alone cannot provide the stroking speed needed to meet rapidly changing process conditions and demands. The new booster design features internal soft seats that yield tight shutoff to reduce unnecessary air consumption and eliminate saturation of positioner relays.

The new booster’s enhanced performance capability proves highly important in applications where a valve positioner alone cannot provide the stroking speed needed to meet rapidly changing process conditions and demands. The new booster design features internal soft seats that yield tight shutoff to reduce unnecessary air consumption and eliminate saturation of positioner relays.

Adding to the VBL’s superior performance is its bypass restriction that enables fast actuator response. The restriction also allows tuning valve response to follow slow signal changes or provide on/off control. This fine-tuning capability does not impact booster deadband. Compact and lightweight in design, the VBL booster features an aluminum body with ¼ NPT input and ½ NPT connections. Internal diaphragms, upper and lower valves, and O-rings are of HNBR. Maximum input signal pressure is 10.3 bar (150 psig) with an input to output ratio being fixed at 1:1.