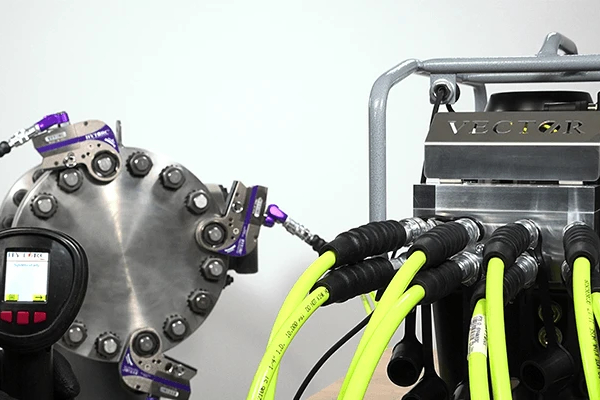

The Simultorc bolting process utilizes multiple Hytorc tools simultaneously on your bolting application. With reduced time during assembly and disassembly, Simultorc allows for fewer passes to complete the job, making the bolt load on the flange face even and accurate. Hytorc tools are officially distributed by UVIT in Italy.

To ensure overall joint reliability, parallel joint closure and eliminate the possibility of leaks, the logical system for any flanged joint is Hytorc Simultorc system. The Simultorc system utilizes multiple Hytorc machines simultaneously on your flanged connections.

Parallel Joint Closure provides substantial productivity enhancements using a hands-free method which increases hand safety and reduces hand injury incidents. This enhanced bolting method, recommended by ASME PCC-1, will reduce any bolting job time by at least 50%.

ASME PCC-1-2013 (Guidelines for Pressure Boundary Bolted Flange Joint Assembly) The use of the Simultorc type of bolting system is recognized by ASME as the preferred method for flanged joint assembly.

Simultorc can be used in conjunction with any of Hytorc in-line reaction fixtures. Simultorc works especially well with the Hytorc Nut, Hytorc Washer, and Smart Stud fasteners which are all integral components of Hytorc total Stretch-to-Load bolting philosophy.

Courtesy of Hytorc.