Due to its ongoing dedication to providing high-quality products and customized services, Neway has earned its reputation as a leading enterprise in the valve industry. Globally recognized for its wide breadth of industry-focused products, the company is committed to continually enhancing the strength of its technology and manufacturing process. Neway’s persistence regarding reliable quality is the cornerstone of its brand power and influence, making it a go-to source for both superior-grade materials and high-end cast and forged valves.

Valve World Americas had the pleasure of speaking with Mr. Zhang Zhuzhu, General Manager of Neway Industrial Materials Division to discuss its progressive history, its commitment to providing exceptional quality products, and where its ongoing craftsman spirit and demand for excellence will lead the company next.

By Laura Wang

Rooted in Consistent Culture

Neway Industrial Materials was established in 2002. The initial goal of this division was to align perfectly with the corporate philosophy of ‘delivering reliable and quality products only,’ by ensuring strict quality control and secure quality castings for Neway valve products.

“Since its establishment, all the castings produced by the Industrial Materials Division have been supplied directly to the Neway Valve division. The key factor that drove this growth was the company’s insistence on upholding its ‘quality first’ mantra,” explained Mr. Zhang. “Over only ten years, Neway Valve developed from a small team to a leading brand in the global valve market.”

By taking the initiative and establishing an in-house materials division, Neway can continually provide products that exceed client standards. For example, as the body and bonnet of a valve are subject to the strictest quality requirements, Neway ensures that both pieces are supplied by its internal division, so that it may verify the quality. The commitment to high-quality products is just one of many ways that Neway remains rooted in the culture of excellence that it was founded on.

Continual Development: Wide Range of Forging and Casting Abilities

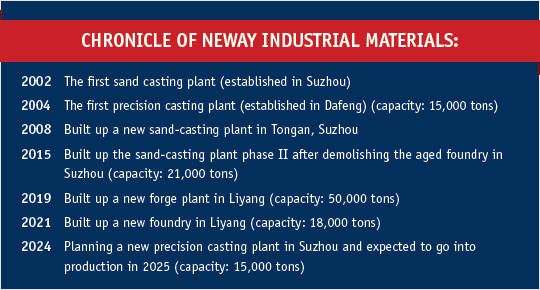

Although it has achieved substantial success, Neway Industrial Materials aims to become a leading cast and forged steel product supplier in the global market. With three advanced foundries, one forge factory, and one new foundry under construction, it is well on its way to achieving its goals. More specifically, this division has built production centers in Suzhou, Dafeng, and Liyang in Jiangsu Province to provide its customers with flexible production capabilities and enable the dedicated technical development of cast and forged steel products and solutions.

To accomplish these milestones, Neway has segmented its production facility according to material characteristics and product application. It has built up several production lines including sodium silicate organic ester self-hardening sand, resin sand, low and medium-temperature wax silica sol, composite process, lost foam (expendable) casting, and so on.

With material options including general carbon steel, stainless steel, duplex steel, alloys material, Neway Industrial Materials can offer a wide selection of thousands of standard and bespoke casted and forged products. Complete casting and forging solutions are therefore being supplied to multiple fields in petrochemical, construction machinery, wind power, mining facilities, and metallurgy. This inaugurates the commercialization of the full Neway Industrial Materials product family.

The application of Neway forged and casted products ranges from high-temperature, high-pressure in cryogenic, corrosive, and other extreme services.

Regarding its forging capabilities, Ne- way Industrial Materials focuses on the development and manufacture of ring forgings. The company also has a semi- automatic production line that integrates the forging, heat treating, and machining sectors and produces roughly 50,000 tons of products annually.

To meet the market needs, Neway is committed to importing new processing technology, which is expected to yield more capacity and facilitate more solutions related to cast and forged products. It has successfully also passed several certifications of international and domestic authorities and obtained qualifications like Nuclear Level I, NORSOK, and more. Besides, it also has CE-PED, DNV, and ABS certificates.

“Since its establishment, all the castings produced by the Industrial Materials Division have been supplied directly to the Neway Valve division. The key factor that drove this growth was the company’s insistence on upholding its ‘quality first’ mantra.”

Flourishing: Forging Competitive Advantage with Craftsman Spirt and the Demand for Excellence

“It is thanks to the craftsman’s spirit and demand for excellence that Neway Industrial Materials has progressed from an exclusive supplier for Neway Valve to a leading player in the global industry,” stated Mr. Zhang. “From material development to processing technique innovation, we always strive to do better in the sector we focus on. We know very well that material, equipment, and processing technology are the three essential factors that determine product performance and quality. Any improvement in these three sectors requires long-term experience gained from meeting the needs of diversified customers. Fortunately, this is where our advantage stands. With excellent technology and accumulated processing skills, Neway Industrial Materials keeps expanding its product lines horizontally to get it- self-prepared for providing professional and effective solutions for the customers.”

To enhance its advantage and boost competitive strength, Neway Industrial Materials is improving through various perspectives, including professionalization, customization, and service.

Professionalization: Its focus on casting and forging business cultivates segmented markets to provide specialized products and solutions. The product spectrum of Neway Industrial Materials can be classified into two categories: ring forgings and cast steel products. Ring forging products are widely used in wind power, construction, and the petrochemical industry. In the wind power industry, the performance of Neway ring forging products is especially noteworthy. They are also widely used as bearings, gear wheels, planet wheels, and sun wheels in wind-driven generators with positive feedback from customers. Mr. Zhang said, “Based on excellent product performance and sound customer feedback, we are confident that the next key growth point of our forged ring products will be the international petrochemical and construction market.”

When it comes to professionalization, the Neway casting products – endorsed by the brand influence of Neway valve products – deserve the reputation that comes from real distinction. The Neway casting products were not launched to the market until last year. These products mainly serve the petrochemical, construction machinery, and metallurgy industry markets. “It certainly awards extra points to the final product by choosing Neway castings, because the Neway brand influence is a great endorsement,” explained Mr. Zhang.

Customization: Keen on product innovation and technical development. With the focus on high-end materials, customized products are created. Neway Industrial Materials features powerful technical strength. It has a technical team of more than 60 professionals and owns several technical patents. As for hardware, Neway has two R&D centers: one in Italy and the other located within the headquarters in Suzhou, China. The company has leading facilities and a CNAS-certified lab. Therefore, the R&D strength is firmly supported by both hardware and software. The company invests significantly in new products and new material development every year. This also helps to keep competitiveness and boost technical innovation. All these strengths and advantages lead to powerful customization capabilities which create the best solution for customers.

Service-Oriented: provide all-aspects quality service, anticipated by the customers. The footprint of Neway valve products is all around the world. In alignment with this, Neway Industrial Materials products are also targeting the worldwide market. Around the world, Neway Group has ten branches, several service teams, and nearly one hundred agents and distributors. With rich experience gained from diversified markets, Neway flexibly creates and adjusts its development strategy according to the local market. This ensures that business runs smoothly. More importantly, customer satisfaction and smooth plant operation are also secured in the meantime.

Potential: Pre-Emptive Strategy to Leverage Development Opportunity

Intelligent Manufacturing

Being in a labor-intensive industry, full- scale intelligent casting is not an option as it harms casting product performance and may even cause product loss. For this reason, the Neway team imported automatic equipment and intelligent robots to the spots smartly chosen based on in-depth knowledge of casting and process techniques. The aim was to improve efficiency and more importantly, to improve the machining accuracy, quality, and performance of each product.

Environmental Care

In the development of Neway Industrial Materials, upgrading casting and forging plants is an ongoing practice. As one of the reasons for upgrading, much attention and importance is placed on environmental care. The traditional casting process features outdated equipment, harsh working conditions, and limited additional value of the product. These are all obstacles to the development of the casting industry and restraining the competitiveness of traditional foundries. Neway’s solution starts with an environment-friendly processing technique. Under these guidelines, water glass (soluble silicate) is chosen for sand casting as it is cleaner. Neway imposes comprehensive thinking regarding ecology when designing each step of the manufacturing process. Exclusive chambers and dust collectors are available respectively for grinding, welding, cutting, and other heavy polluting works. Pipeline transportation is also used to further reduce environmental issues. At Neway, the manufacturing process is designed in line with the global Eco-protection objective. These considerations and precautions lead to the potential for future development.

Talent Pool

Neway considers talent as a premium asset. It has built up multiple training systems and programs, which can be reflected by the stable Neway team and their level of professionalism. “As a globalized company, Neway takes diversity and inclusiveness seriously. Different ideas and opinions are equally appreciated here. We encourage people to be creative and use their imagination. We believe that an open and inclusive atmosphere leads to best performance. It is highly expected that at the influence of the above factors, the whole Neway team works closely like a big family— not only in terms of cooperation for work. Each Neway worker might share, to some extent, the same values and cultural identity. In pursuance of continued excellence, we are determined to keep innovating and improving according to customer needs,” Mr. Zhang continued.

By supporting exceptional product quality with good materials, Neway Indus- trial Materials contributes to the sound reputation of Neway valve products, the Neway brand, and diversified solutions. Mr. Zhang stated, “Our development is guided by the needs of the market. In the future, we will have different materials and nonferrous metals available as our material options, such as high temperature alloy, nickel-based and cobalt-based alloy, cast copper, and cast aluminum. A broad range of material options makes us a solution provider. However, to match up to the expanding material options, our key direction of development is diversified processing techniques.”

“For this purpose, we will enhance the investment in R&D to further optimize product performance and production efficiency. Neway is actively developing international markets and enhancing co-operation with overseas customers to boost brand recognition and influence. The brand is a nominal matter from the perspective of the customers. The core of our product value is always the technology, and quality is always the foundation. Striving to improve in these aspects, we have the confidence to boost the production of castings and ring forging products, as well as better solutions involving casting and forging products in the coming years,” concluded Mr. Zhang.