Valve World Americas recently talked to Mr. Elvin Feng, Vice President of the Valve Division at Neway Valve, to learn more about the company’s latest products & services, R&D capabilities, and pioneering spirit.

By Xue Guanpu & Liu Zhi

Located in the high-tech district of Suzhou City, Neway Valve is one of the leading valve manufacturers in China. Dedicated to developing and making industrial valves, Neway is skilled in offering a full set of valve solutions to satisfy continual demand from the market. Largely applied in the oil & gas, refining, petrochemical, chemical, offshore, power plant, nuclear power, mining, oil & gas transmission pipelines, and air separation industries, Neway’s products cover a wide range of valve types including: gate, globe, check, ball, butterfly, nuclear, subsea, control, safety & wellhead valves, as well as associated equipment. It is also noteworthy that Neway sets very stringent management standards for its whole manufacturing process, of R&D, casting/forging, machining, assembly, painting, and testing.

After 20 years of hard work in the European, American, and Middle Eastern markets, Neway now enjoys an outstanding reputation and has become a model company among global valve producers.

Mr. Elvin Feng has worked at Neway Suzhou for ten years and is now in charge of the company’s overseas operation. When asked about what he considers to be Neway’s most valued quality, he answers without any hesitation “innovation.”

“It is, moreover, a fundamental strength to be able to keep an enterprise in a vigorous and competitive state,” he says. As a matter of fact, innovation perfectly implies the core spirit contained in its name (Neway) and this quality has penetrated all aspects of Neway’s management and development.

Transformation to Clean and Renewable Energy

In 2019, at the Valve World Asia Conference and Exhibition, Mr. Feng expressed that Neway was going to develop more high-end products for the clean energy market, including cryogenic valves and oxygen valves. “We can see that there is an ongoing transformation from traditional energy to clean and renewable energy simply because there is an obvious increase in the demand for clean energy valves. Amongst these, cryogenic valves show the most visible growth factor.”

The considerable investments that Neway has put into high-end valves for the clean energy industry has led it to achieve a number of accomplishments. With regard to a LNG project in North America; Neway provided large-scale 3’’-24’’ CL150-CL600 triple offset butterfly valves with both laminated and solid seal rings. For another project in China, Neway produced 1/2’’ class 300 cryogenic bellow globe valves for liquid hydrogen tanks. In addition, Neway’s high-pressure top-entry cryogenic ball valves have successfully passed strenuous project requirements and inspection tests. Valves were supplied in sizes up to 12” maximum diameter and pressure classes up to 1500 lb. This project shows Neway’s ongoing successful production of on-off ball valves in the gasification transformation applications of an LNG terminal.

Furthermore, Neway plays an active role in the nuclear power market. In the nuclear fission industry, Neway has made significant breakthroughs in the European market by supplying 2” 2,500 lb bellows seal globe valves of nuclear class 2 and 3. Moreover, as the first Chinese valve manufacturer to join a nuclear fission project outside China, Neway has provided diamagnetic and anti-seismic pneumatic ball and globe valves for the reactor cooling system of a European ITER (International Thermonuclear Experimental Reactor) project.

Mr. Feng emphasized that there will be changes to the trends in the energy market in the future. “European end users, such as Shell, Total, BP, and Equinor (originally named Statoil), have actually undergone a huge transition by beginning to explore clean energy (which includes natural gas, solar energy, wind energy, hydrogen and nuclear power), after originally starting out in oil exploration. This transformation became more apparent when Shell acquired BG (British Gas). The use of oil and coal is decreasing, and I think end users from other regions of the world will follow this line.”

Keep Products Competitive

The products offered by manufacturers are paramount in capturing the market. To keep products competitive, Neway places great importance on its R&D investments. With a technical team of over 200, Neway has established R&D centers in China, the U.S., and Italy. “Each year we invest about USD $13 million into R&D and Neway continually develops new products to meet the market demand; as is the case with eccentric ball, emergency shutdown, cryogenic triple offset butterfly, and subsea valves,” continues Mr. Feng.

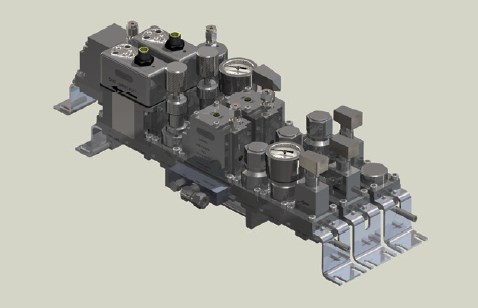

Neway’s main production line now consists of 6D pipeline, cryogenic, fully welded, and actuated valves. Among these products, the demand for pipeline and cryogenic valves shows a significant rise. “6D pipeline valves, including ball, slab & expanded gate, and full open piggable check valves (which are used in pipeline applications in the midstream industry), are the company’s fastest growing products for the American market. With techniques continually maturing, we are especially proficient in producing soft-seal, metal seated and fully welded technology for pipeline valves,” says Mr. Feng.

When it comes to smart technology, Mr. Feng admits that Neway is putting in a lot of effort. Neway manufactures intelligent products, for instance, on-off valves and sequence valves. “Our on-off valves find a good market in the Middle-East and Europe, having an annual growth of 50%. Only by precisely controlling the magnitude of the torque of the on-off valve can its competitiveness be strengthened. Neway is now carrying out research as to how we can monitor the state of on-off valves online. In this way we can analyze the valve function by examining the data transmitted to a central computer,” continues Mr. Feng.

He further points out that Neway has always placed an emphasis on combining new technologies into products. “We have also realized that the valve industry is going through a lot of changes at present. In the past we carried out a lot of work improving valve hardware and now it is time for a change. Our primary choice for the future will be to increasingly look to combine valve hardware to system software and to provide more value-added services to our customers,” adds Mr. Feng.

Working Towards Optimal Solutions

As a response to ever-changing market demands, the pre-sale and post-sale services provided by quality manufacturers have become more detailed and professional. For Neway, both services are of equal importance. Professional pre-sale services help to avoid many problems that customers might come across in practice. As such, Neway has established a team of application engineers, whose aim is to offer timely and professional technical backup for customers.

“This team of application engineers provides technical support, helps clients in connection with valve selection, technical specifications, and shares their onsite experiences with clients during the pre-sale stage. In general, they offer optimized and reliable valve solutions to our customers,” elaborates Mr. Feng.

“Sometimes we discover that a previous valve selection made for a client might not still be the best choice due to ever improving technology and innovation at Neway. To ensure that we are therefore able to provide the client with the best possible solution, we need to thoroughly understand their operating conditions. By doing this our experienced engineers will provide them with an economical and reliable solution. The engineers on our team have considerable knowledge about valve applications and an excellent insight into our customers’ needs and challenges. If our customers come across any problems with their on-site operation, then the engineering team will solve these problems, gathering data where necessary for further research and ongoing improvements. For our clients, this is truly a value-added service,” adds Mr. Feng.

Anti-risk Capability

The COVID-19 pandemic sweeping the world has put tremendous pressure on the survival of all professions and trades. Neway has fortunately been carrying out its automation upgrades for years and these have paved the way for a smoother transition during this difficult time. Having benefitted from this early preparation work, Mr. Feng says the impact of COVID-19 has been limited for Neway to date.

Neway was amongst the very first group of enterprises that were permitted by the Chinese government to restart production. “The automation upgrades we have done gave great support to our production recovery. Apart from upgrading our warehouse, we have also upgraded our production lines for welding, surface treatment, assembly, and painting. We have not undergone a 100% transformation to automation yet, but we have raised the automation level of our production processes significantly.”

“Automation requires flexibility in both technical design and in the production lines because most of our clients ask for tailor-made products. Therefore, our operating staff also needs to be flexible. From 2018 onwards, Neway started to train staff to possess multiple skills. We have benefited considerably from this preparation work: multi-skilled employees can be allocated to different tasks to safeguard production. Another reason we were able to get back to full operational capacity as quickly as we did is because we manufacture in-house and control our own production as a vertically integrated manufacturer. We control our own castings, forgings, welding, machining, and testing. This vertical integration allows Neway to quickly pick up production,” continues Mr. Feng.

In addition, remote inspection increasingly plays an important role at the current time. “This new form of inspection has been recognized and utilized by most of our customers. With the pace of procurement slowed down by the COVID-19 pandemic, remote inspection has been adopted to not only improve working efficiency but to ensure that we get and keep our business efficient, optimized and always on track.” Mr. Feng continues, “Neway started to conduct research on this topic with a world-renowned oil & gas company in 2019 and our aim was to provide a cost-effective plan for our customers and maximize efficiency for ourselves.”

“To put it simply, remote inspection is achieved through a pair of glasses worn by our operating staff. The glasses contain a camera connected to the customer’s PC. Based on the instructions given by the customer, the operator can show what the client wants to check synchronously. As a secondary form of verification, another camera provides an elevated overall view of the facility. It is as if the customer is controlling the situation from behind the screen,” Mr. Feng explains. “Moreover, the flow curve of valve pressure testing is recorded by our software. It cannot be modified manually, so there is no need to send someone to recheck the situation if the record can be considered accurate.”

The Future

So how has Neway managed to successfully establish a foothold outside China? “First of all, we set up a self-contained supply chain from raw material processing right through to assembly and final testing so all the key processes within valve manufacturing are managed by Neway itself. Second, Neway values talent, especially global talent. Third, we encourage innovation,” he says. “As for the future challenges coming from the global market: Neway needs to create more opportunities to demonstrate its strength and competitiveness. The biggest challenge lies in setting Neway apart from the competition through our research competencies, product quality, and services.”

“Neway positions itself as a full-fledged valve solution provider and we will continue to invest more on high-end products. Our aim is to provide standard products with higher efficiency, better quality, and stronger competitiveness through continuous improvement and automation upgrading. For high-end products, Neway continues to advance valve performance with ever increasing technological maturity and stability.” Summing up, Mr. Feng says: “Our high-end products are quite competitive in the Americas. We are open to everyone and warmly welcome customers from America and throughout the world to pay us a visit!”