Since the adoption of the 1970 Clean Air Act (CAA) within the United States of America (USA), many rules have been developed to reduce fugitive emissions across all industries. Using these rules, the USA took the first step towards the development of work practices. In addition to the use of the rules which drove a reduction of fugitive emissions, test methods were created on how to perform the required tasks within these rules. One of the main test methods created was the United States Environmental Protection Agency’s (USEPA) Appendix A-7, or more commonly, Method 21.

By Bronson Pate, Client Relationships Manager – TRICORD Consulting

Method 21

Although Method 21 is typically thought of as the backbone to almost all of USEPA regulations, individuals continue to have difficulty following the test method. Method 21 is a document that consists of roughly 17 sections and currently drives the reduction in fugitive emissions. It has been adopted in many countries around the world, with the goal of achieving the same reduction results that are being seen in the USA.

While each of the 17 sections are vital to the overall impact the implemented processes can have on the reduction of emissions, this article will focus on section and subsection 8.3.1. This section outlines how to actually perform Method 21, while in the field.

Overview of Section 8.3.1

Section 8.3.1 Type I – Leak Definition Based on Concentration

8.3.1 Type I – Leak Definition Based on Concentration

Place the probe inlet at the surface of the component interface where leakage could occur. Move the probe along the interface periphery while observing the instrument readout. If an increased meter reading is observed, slowly sample the interface where leakage is indicated until the maximum meter reading is obtained. Leave the probe inlet at this maximum reading location for approximately two times the instrument response time. If the maximum observed meter reading is greater than the leak definition in the applicable regulation, record and report the results as specified in the regulation reporting requirements.

In plain ‘English,’ section 8.3.1 begins by detailing the process that should be followed to test a component interface. The first step is to place the monitoring probe tip at the surface of the potentially leaking interface. This means that the monitoring personnel should place the testing instrument so that it is metal to metal; if rotating shaft equipment is being used, a different process, which is detailed below, is required. The second step is to move the probe tip along the leak interface while observing the instrument readout for an increased reading. The final step, once all of the potential leaking interfaces for the specific component have been traced, is to return the probe tip to the point where the highest reading was observed. This reading should be recorded for roughly twice the instrument response time. The maximum reading that is observed is the one that the operator should save and report.

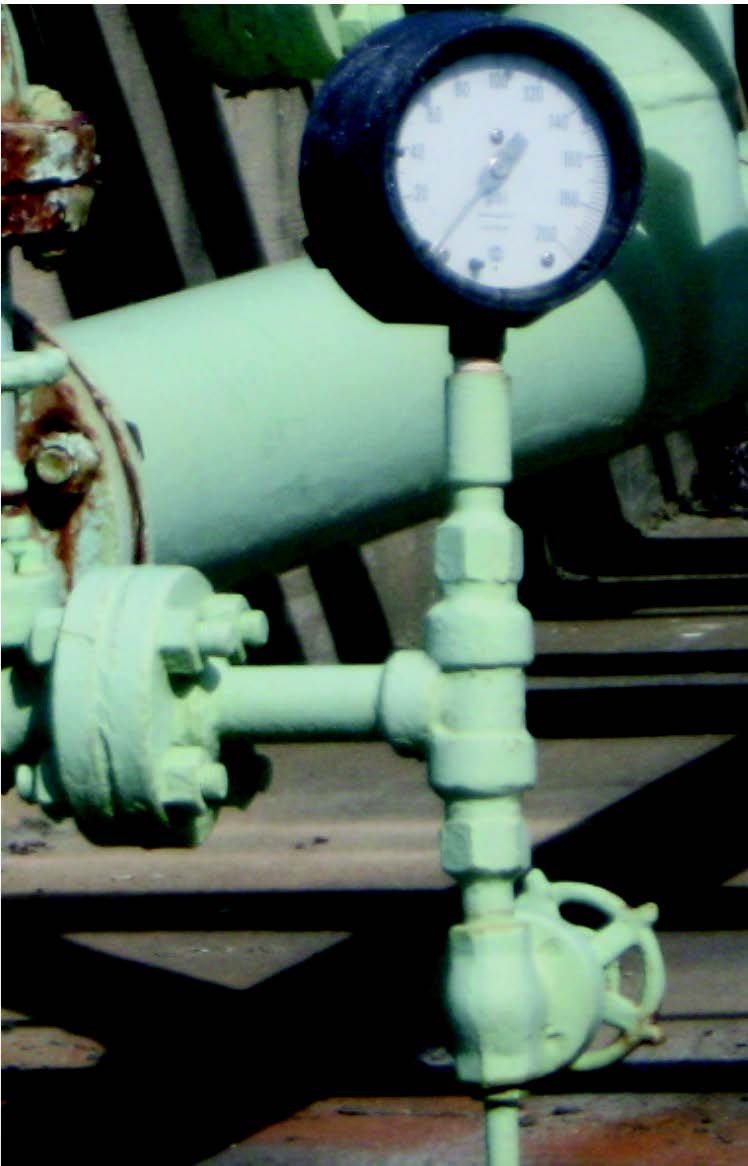

Section 8.3.1.1 – Valves

Valves are typically the most common component found within the LDAR program and consist of the most leaks. The monitor will be directed to place the probe tip on the leaking interface of the packing and stem area. It is important to test the complete circumference of these areas. Once they have monitored both of these areas they will turn their attention to monitoring the bonnet flange area, if it is not wrapped in insulation.

8.3.1.1 – Valves

The most common source of leaks from valves is the seal between the stem and housing. Place the probe at the interface where the stem exits the packing gland and sample the stem circumference. Also, place the probe at the interface of the packing gland take-up flange seat and sample the periphery. In addition, survey valve housings of multipart assembly at the surface of all interfaces where a leak could occur.

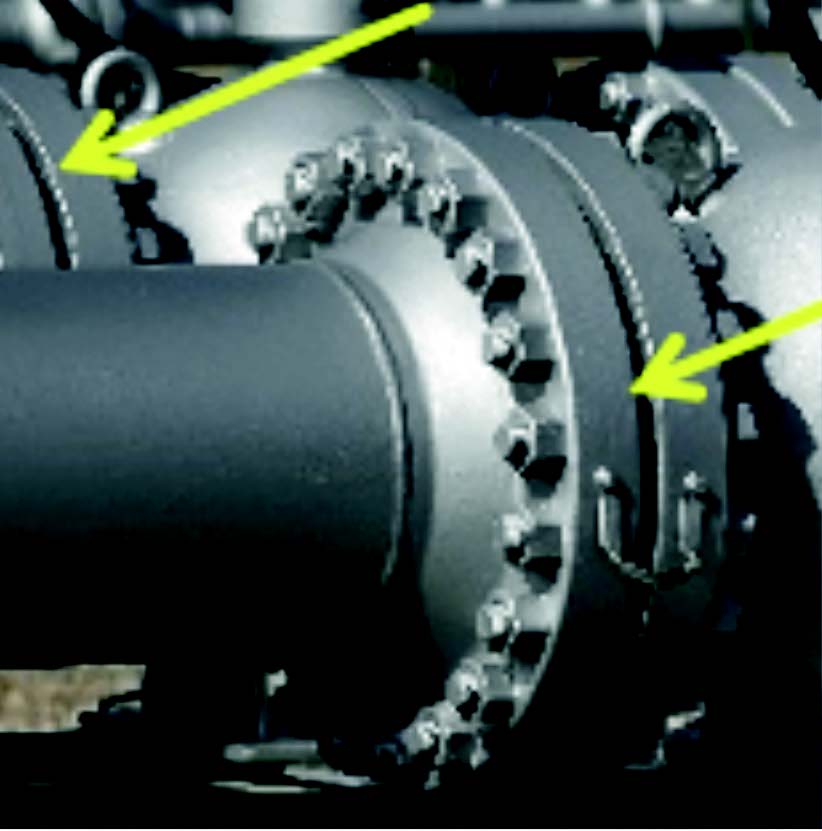

Section 8.3.1.2 – Flanges and Other Connections

Flanges and ‘other’ connection component directions can be found in 8.3.1.2. For these applications the monitoring personnel will be instructed to place the probe tip at the interface of the joint/connection and monitor the circumference.

8.3.1.2 – Flanges and Other Connections.

For welded flanges, place the probe at the outer edge of the flange gasket interface and sample the circumference of the flange.

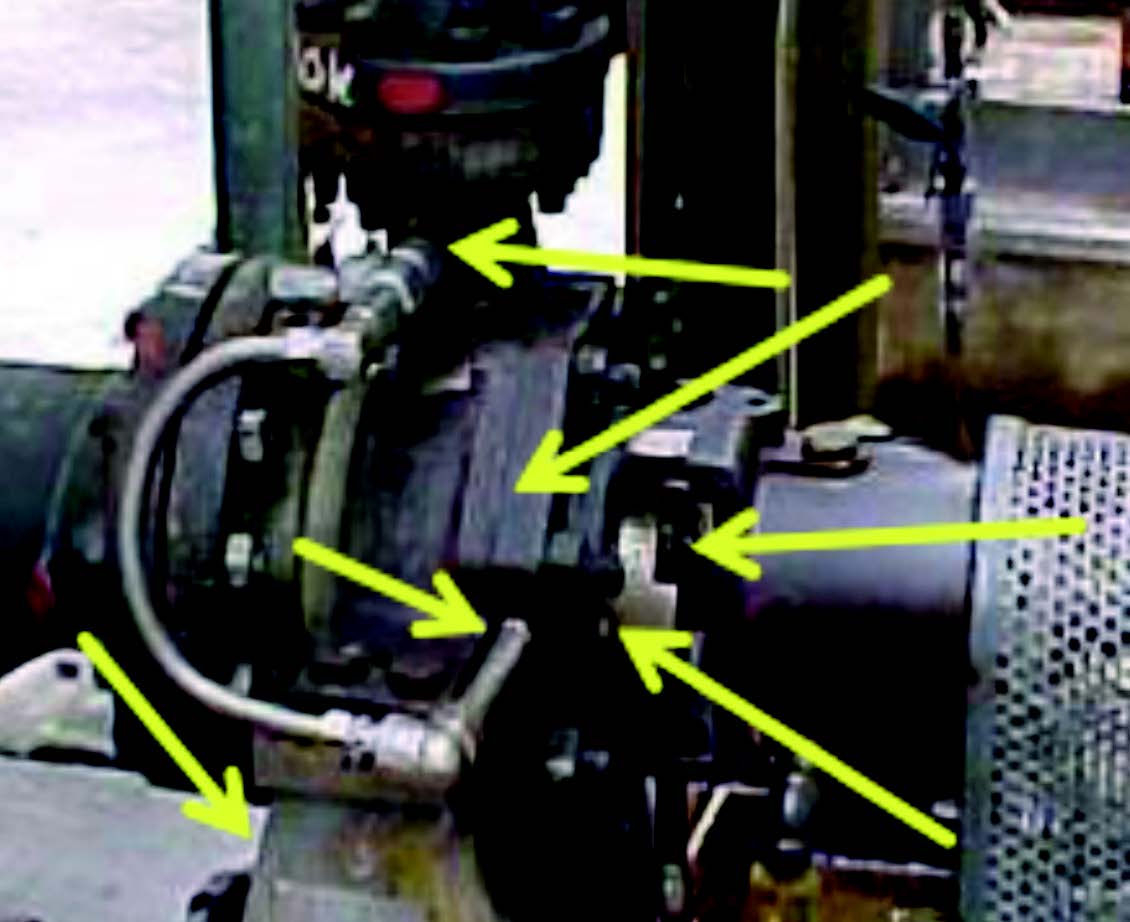

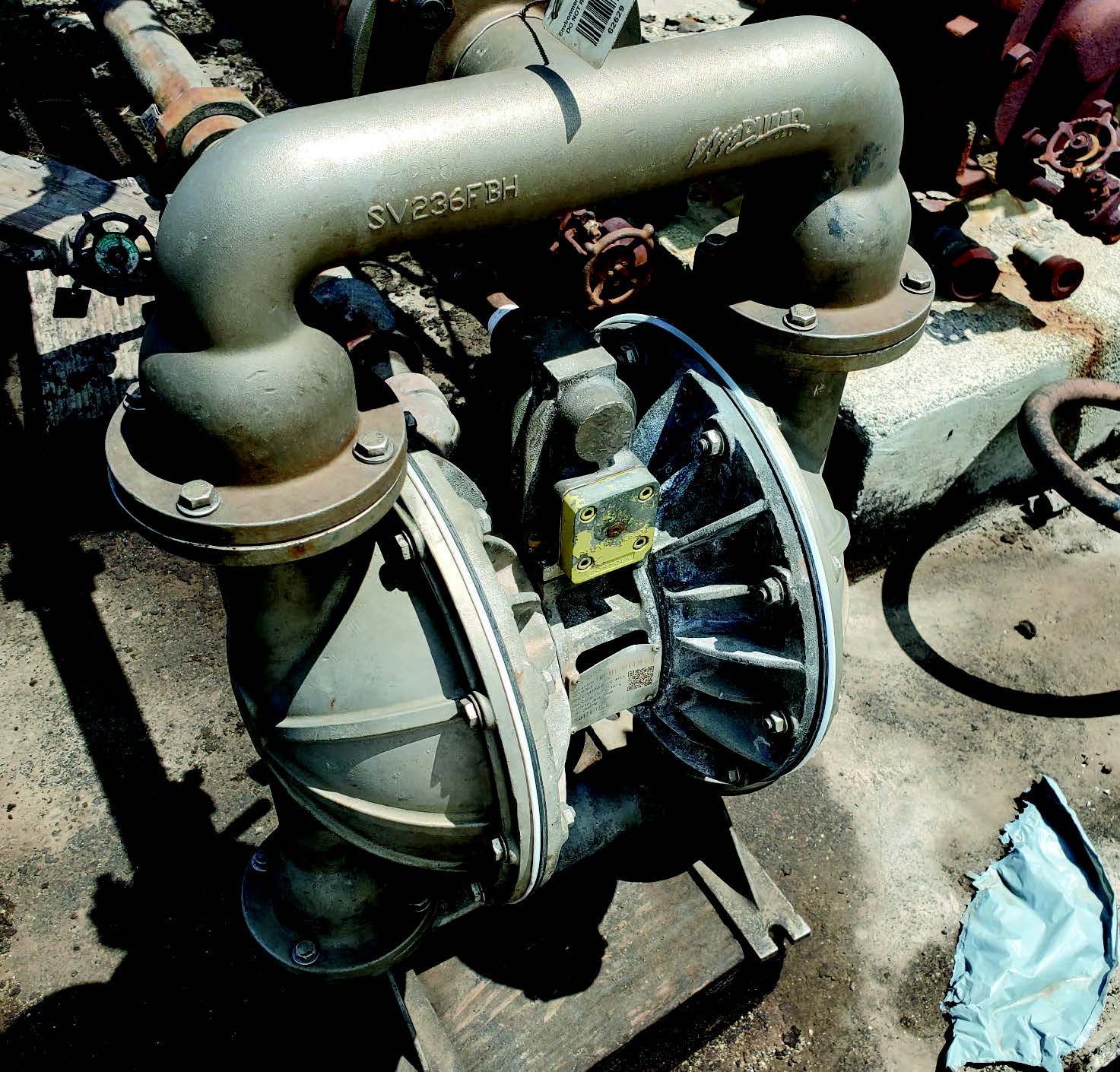

Section 8.3.1.3 – Pumps and Compressors

Pumps and compressors will have multiple areas in which a potential leak can be found. If any moving parts are observed, the monitoring personnel is allowed to let the tip of the probe float at most 1 cm from that part. For all the other areas, place the probe tip on the leak interfaces and traverse the circumference.

8.3.1.3 – Pumps and Compressors.

Conduct a circumferential traverse at the outer surface of the pump or compressor shaft and seal interface. If the source is a rotating shaft, position the probe inlet within 1 cm of the shaft-seal interface for the survey. If the housing configuration prevents a complete traverse of the shaft periphery, sample all accessible portions. Sample all other joints on the pump or compressor housing where leakage could occur.

Section 8.3.1.4 – Pressure Relief Devices

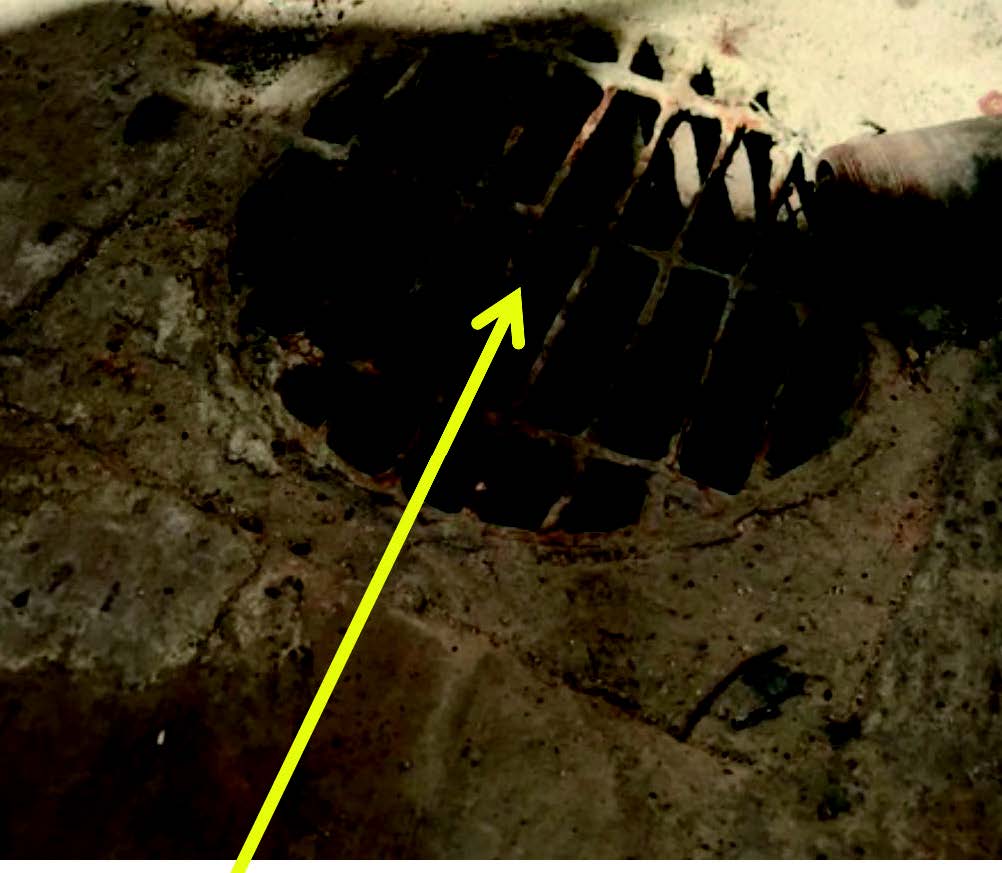

For Pressure Relief devices that vent into the atmosphere, as shown in Figure 9, the probe tip should be placed at the center of the ‘horn.’ If the ‘horn’ is out of reach, the ‘weep’ hole (noted by the green arrow in Figure 9) is the best alternate. 8.3.1.4 provides a little more detail on interfaces, but overall, these two locations are going to be the main areas to review.

8.3.1.4 – Pressure Relief Devices.

The configuration of most pressure relief devices prevents sampling at the sealing seat interface. For those devices equipped with an enclosed extension, or horn, place the probe inlet at approximately the center of the exhaust area to the atmosphere.

Sample other types of nonpermanent joints (such as threaded connections) with a similar traverse.

Section 8.3.1.5 – Process Drains

For Process drains, the monitoring location is at the center of the opening to the atmosphere. If the drain is covered then it is important to monitor the circumference of the drain covering.

8.3.1.5 – Process Drains.

For open drains, place the probe inlet at approximately the center of the area open to the atmosphere. For covered drains, place the probe at the surface of the cover interface and conduct a peripheral traverse.

Section 8.3.1.6 Open-ended Lines or Valves

For open-ended lines or valves in 8.3.1.6, the probe tip should be placed in the center of the opened area. Do not pass the plane of the opened area though when monitoring.

8.3.1.6 Open-ended Lines or Valves.

Place the probe inlet at approximately the center of the opening to the atmosphere.

Section 8.3.3.1 and 8.3.3.2 – Alternate Screening Procedure

For alternate methods of testing refer to sections 8.3.3 of Method 21. This section provides insight into the soap solution method which uses the appearance of bubbles as the solution is placed onto the component to indicate a leak. While this method is not used in a day-to-day LDAR world, it is used by maintenance and operations personnel if a re-monitoring technician is not available.

8.3.3.1 A screening procedure based on the formation of bubbles in a soap solution that is sprayed on a potential leak source may be used for those sources that do not have continuously moving parts, that do not have surface temperatures greater than the boiling point or less than the freezing point of the soap solution, that do not have open areas to the atmosphere that the soap solution cannot bridge, or that do not exhibit evidence of liquid leakage. Sources that have these conditions present must be surveyed using the instrument technique of section 8.3.1 or 8.3.2

8.3.3.2 Spray a soap solution over all potential leak sources. The soap solution may be a commercially available leak detection solution or may be prepared using concentrated detergent and water.

A pressure sprayer or squeeze bottle may be used to dispense the solution. Observe the potential leak sites to determine if any bubbles are formed. If no bubbles are observed, the source is presumed to have no detectable emissions or leaks as applicable. If any bubbles are observed, the instrument techniques of Section 8.3.1 or 8.3.2 shall be used to determine if a leak exists, or if the source has detectable emissions, as applicable

Figure 10.

Final Thoughts

As can be seen, each component has its own specific section written into how to properly monitor it, per Method 21. Although this test method is very detailed in explaining how to monitor each interface, leaks are still getting missed. So why is that? Truly it is all about the speed, angle of the probe to the leaking interface, and making sure that the probe is truly on the leaking interface. By understanding the test methods, and specifically the monitoring locations, an operator or monitor will be able to more effectively find and address the present leaks. With a more comprehensive understanding of Method 21, the addition of Certified Low Leaking Technology, and the advancements of the standards associated with API 622, API 624, API 641, ASME 16.20, and ISO 15848, individuals will be better able to achieve a true reduction in emissions.

Bronson Pate is a Client Relation-ship Man-ager with TRICORD Consulting, LLC. Bronson is an LDAR Subject Matter Expert with more than thirteen years of professional experience within the industry. He has participated in and/or led over 275 third party LDAR audits and has worked with multiple facilities to develop LDAR programs both domestically and inter-nationally.

Bronson Pate is a Client Relation-ship Man-ager with TRICORD Consulting, LLC. Bronson is an LDAR Subject Matter Expert with more than thirteen years of professional experience within the industry. He has participated in and/or led over 275 third party LDAR audits and has worked with multiple facilities to develop LDAR programs both domestically and inter-nationally.