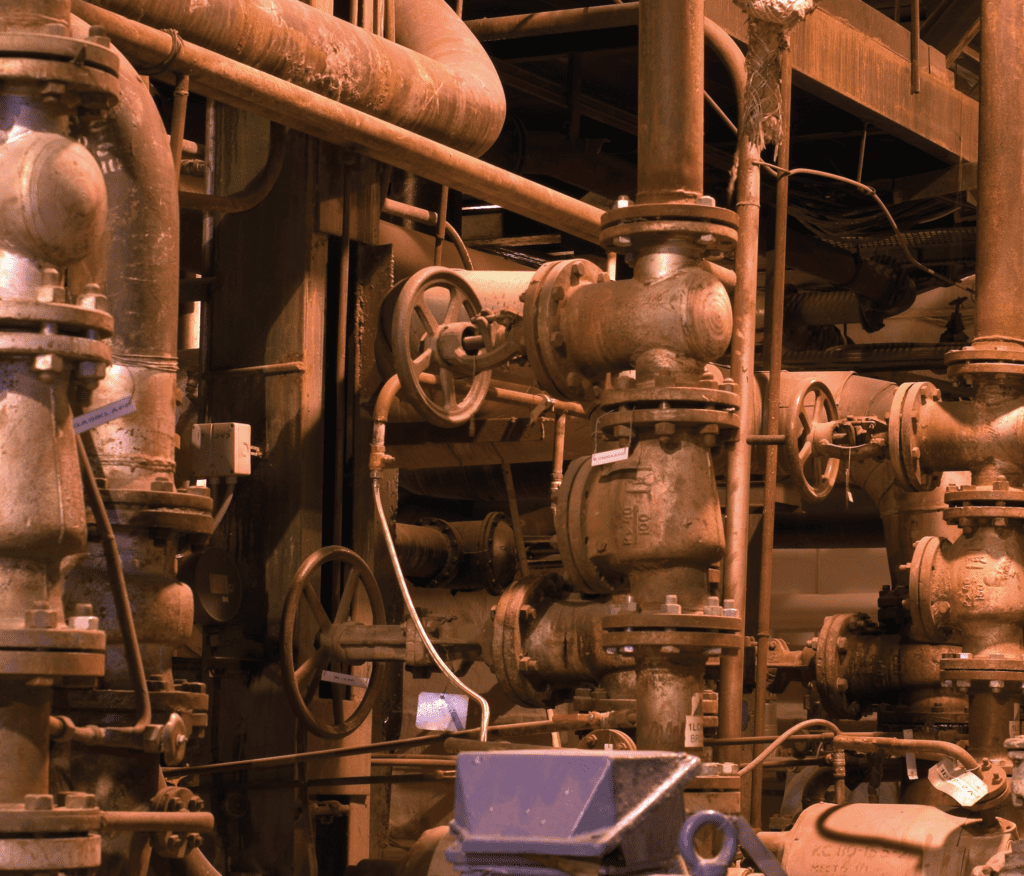

Valves, those useful assets that control liquids in factories, can get old and cause trouble for businesses. However, there is a clever way to fix these components instead of throwing them away and replacing the parts. This is called valve refurbishment, and it is becoming increasingly popular due to its smart and eco-friendly way of making valves work like new again.

By Vighnesh SS, Business Development Engineer for Valve Servicing, Repair, and Refurbishment Services – EFCO Maschinenabu India.

The Valve Refurbishment Process

There is a step-by-step process involved in valve refurbishment that covers inspection, disassembly, lapping, welding, dye penetration testing, blue matching, assembly, and testing.

Valve Inspection

The refurbishment process begins with a comprehensive inspection of the valve. Highly skilled technicians examine the valve’s exterior, internal components, and functional elements. They assess the extent of wear, corrosion, and damage, identifying areas that require repair or replacement.

Valve Disassembly

After inspection, the valve is carefully disassembled. Skilled technicians remove the valve’s bonnet, stem, disc, seats, and other relevant components. This disassembly allows for a thorough examination and precise refurbishment of each individual part.

Lapping

Lapping is a critical step in refurbishing valve seats and discs. Specialized lapping compounds are used to achieve a precise and uniform surface finish, ensuring optimal sealing. The lapping process removes regularities, scratches, or pitting on the sealing surfaces and restores their functionality.

Welding

In cases where valve bodies or other components have experienced severe damage or corrosion, welding may be necessary. Skilled welders repair or replace damaged sections, restoring the structural integrity of the valve. Welding is performed using suitable techniques and materials that comply with industry standards and specifications.

Dye Penetration Test

After welding or repairing the valve components, a dye penetration test is conducted. This non-destructive testing method ensures the welds’ integrity and identifies any potential defects. A special dye penetrant is applied to the welds, and excess dye is hence removed. The dye penetrant reveals any surface-breaking defects, which are then addressed before proceeding.

Blue Matching

Blue matching is a process that ensures proper contact and alignment between the valve seat and disc. A blue dye is applied to the sealing surfaces, and the valve is assembled. Upon disassembly, the blue dye transfers to the areas where contact occurs and indicates any irregularities. This helps technicians adjust the components to achieve optimal seating and eliminate any potential leakage points.

Assembly and Testing

After refurbishing the valve components, the valve is reassembled using new seals, gaskets, and other necessary parts. Skilled technicians ensure proper alignment and torque settings during the assembly process. Once assembled, the valve undergoes rigorous testing. This includes pressure testing, flow testing, and functional testing to ensure its performance meets or exceeds specifications.

Why Refurbish Valves?

Save Money

In business, saving money is important. Buying new valves and dealing with the installation and time it takes can cost a lot. With valve refurbishment, valves are fixed at a lower cost. It is like giving valves a low-cost makeover. By choosing refurbishment, it is possible to save money and utilize it for other important things, such as growing a business. Imagine a production line stops because of valve issues, resulting in a larger problem. Replacing valves can take a lot of time and effort, causing big disruptions and making everyone frustrated. However, valve refurbishment is a faster and easier way to get things back on track. Experts can come to a business or take the valves to a special workshop to fi x them quickly. That means less waiting and more time in production.

Helping the Planet

Businesses are also starting to be a part of the trend to be environmentally conscious. Instead of throwing valves away and producing more garbage, refurbishment gives those valves another chance. Similar to recycling, only for valves, reusing and wasting less can help individuals to make the world cleaner and happier.

Valves That Work Even Better

When valves get refurbished, it is not just about fixing them – it is about making the valves work even better. Skilled technicians check the valves, replace old parts, and use new things to improve them as a whole. Refurbished valves are like superheroes of valves as they work well and do not leak. That leads to a better and safer workplace for everyone. When it comes to valve refurbishment, there are individuals who know their valves extremely well: the valve experts. These experts can offer special help and advice for one’s needs. Valve experts can tell how to make valves work at their best, as well as suggest neat changes and demonstrate the best way to care for a valve. It is like having a friend who knows all about valves.

To Sum Up

Valve refurbishment is a comprehensive process. Skilled technicians meticulously refurbish each component, restoring the valve’s performance and efficiency. This detailed work is a great way to save money, get things done quickly, help the environment, and make valves work like new again.

Whether it is globe valves, ball valves, butterfly valves, gate valves, or angle valves, the refurbishment process ensures their optimal functionality and contributes to the smooth operation of industrial systems. So instead of throwing away old valves, think about giving them a chance to work again through refurbishment. It is the smart and eco- friendly way to make a business and the world a better place.