Since its establishment in 2010, International Standard Valve (ISV) has gone above and beyond for its customers, providing high-quality valves assembled and made in the United States. With a customer base that spans coast-to-coast, a vast portfolio that services several industrial sectors, and a deep respect for its employees’ talents, skills, and contributions, ISV has earned the trust of customers worldwide.

Valve World Americas had the opportunity to speak with Michael O’Quinn, President & CEO, and Pam Olson, Marketing Director, at ISV, about the company’s dedication to service, its asset integrity and reliability, and the future of this influential company.

By Angelica Pajkovic

Dynamic Growth

After taking the industry by storm with its introductory leaps and strides in valve production, little room remained for baby steps on ISV’s blueprint; even in its infancy, the company hit the ground running. With-in the first year of its establishment, ISV received its ISO 9001:2008 Quality Management System certification, followed closely by the API 6D certification for U.S. Production.

The company saw its first year through with the implementation of its core competences in two key areas of valve manufacturing: fully code compliant ball valve products, and a multi-layered quality assurance program. It also saw the establishment of an impressive ERP system, and the development of surveys, supplier relations, and product designs, all while maintaining a targeted focus on pressure and performance test equipment installation.

Now, in 2022, while continuing its dedication to developing fully API and ASME code compliant general and special service valve products, ISV is looking to connect with its customer base in new ways. Namely, by offering new custom solutions to solve problems at the end user level. “Since our inception, we have been primed for growth,” explained O’Quinn. “We are in the midst of transition and evolution and are very excited by the direction our company is headed.”

Developing New Solutions

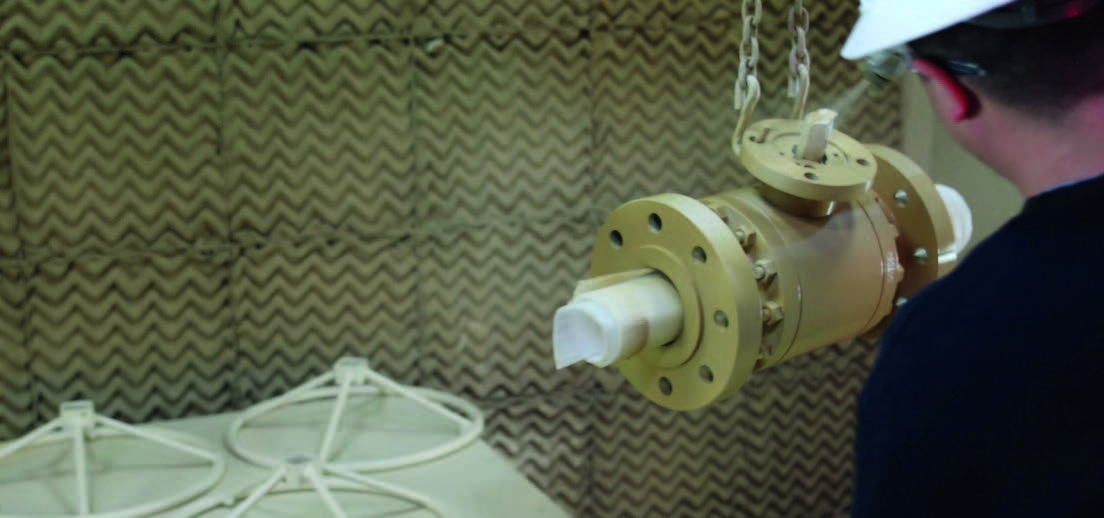

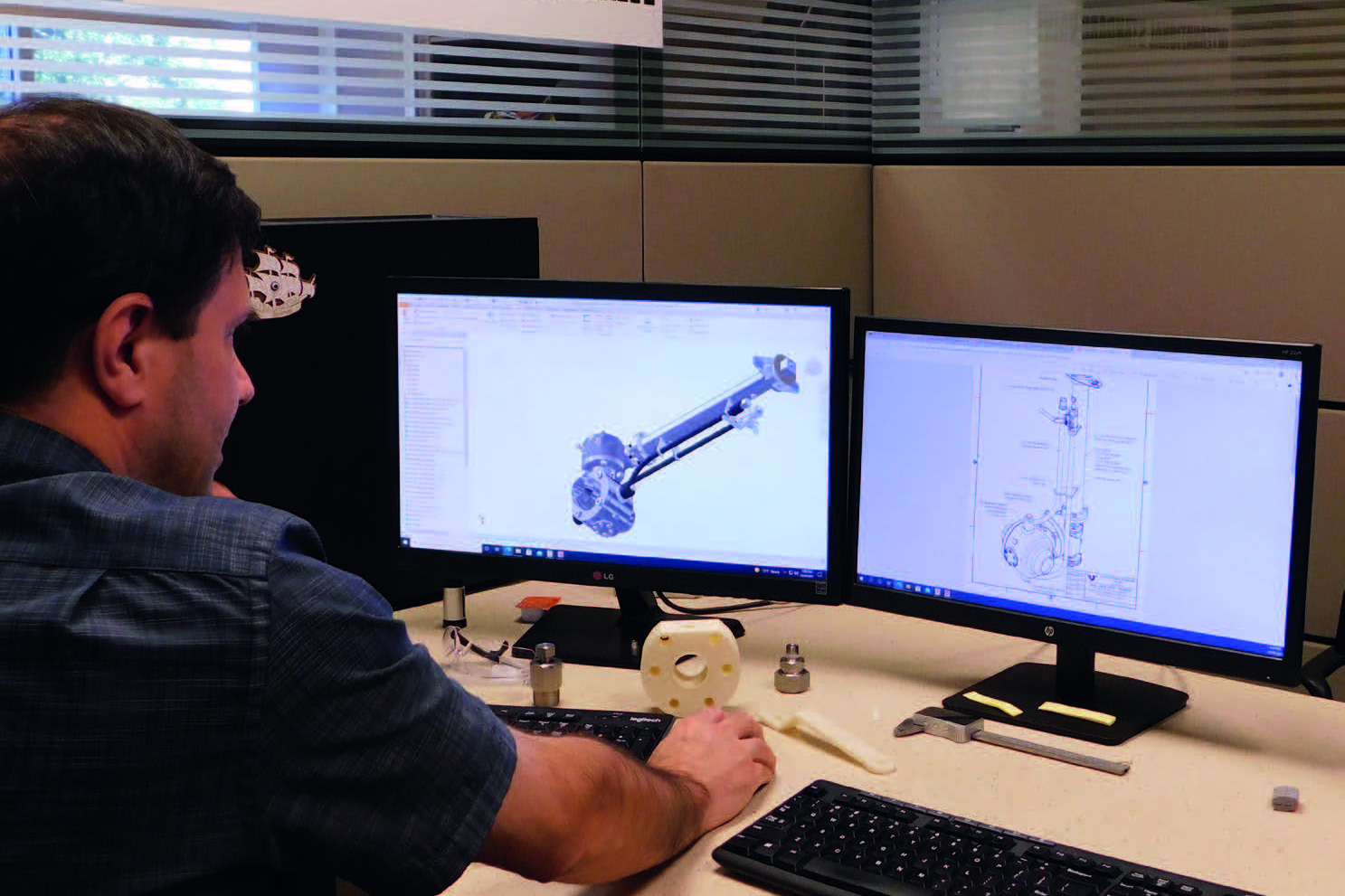

How does ISV deliver on this promise? According to O’Quinn, this can best be seen through the company’s broad breadth of products that fit downstream, midstream, and upstream applications. After 12 years in operation ISV has earned a reputation for providing customers with unique valve designs including those for special service, such as cryogenic valves, and metal seated floating and trunnion mounted ball valves. These designs employ up-to-the-minute engineering technologies geared towards enabling timely yet precise solutions to valve applications of various demands.

The Americas, West Africa and the Middle East are among the key loyal users of ISV products, and for good reason. “Our product range can be characterized as wide ranging, since we cover several API major valves categories as offered products. Standard features of all ISV ball valves include NACE compliance, lockable levers & gear operators, an anti-static device, and fire-safe tested to API 607 products,” said O’Quinn. If those qualifications were not enough, all ISV trunnion mounted ball valves are double block and bleed designed with emergency sealant injection ports.

In conjunction with its endeavour to keep a finger on the pulse of industry expectations, ISV commits to observing the respective statuses of ASME, API, MSS and ISO standards, as well as to actively participating in numerous industry-related task groups. This approach allows the company to remain in touch with the trends observed among its customer base, and to accordingly expand its provision of valves for mid-stream, offshore oil and gas, and industrial applications.

“One trend that has become more evident to us recently, especially in the mid-stream sector, is the heightened need for fully welded ball valves in the marketplace. To address this need, we have begun to manufacture fully welded body ball valves in our Stafford, Texas facility,” stated O’Quinn. “By doing so we are able to provide our customers with solutions to problems that have not yet taken place.”

ISV’s extensive product line is backed by careful detail. “We are very proud of the ever-increasing range of floating and trunnion type ball valves that are engineered, assembled and tested at the Stafford facility,” Michael shared.

“Our production in Stafford includes API 6D trunnion mounted ball valves, as well as a wide range of API 608 & ASME B16.34 industrial floating type ball valves in flanged ends, threaded ends and socket weld end configurations. Pressure ranges include up through ASME Class 2,500.”

Extensive Offerings Meet Expansive Reach

Diversifying its product range and staying one step ahead of the industry with key products suitable for a variety of industries is a factor integral to ISV’s continued success. It is for this reason that the company has also recently developed a range of high-performance HP butterfly valves which will lead it into additional markets into 2022.

“While we maintain a very large mix of floating style ball valves that meet the requirements of general industrial applications and customers, as well as oil & gas up-stream, midstream and downstream, we are continually seeking to grow our products’ acceptance and approvals with the related end users and contractors in each industry segment,” explained O’Quinn.

Bearing in mind that the current market demand necessitates shortened delivery times, ISV acknowledges that consistently seeking to improve on its timely delivery is at the forefront of ISV’s priorities. However, timeliness is never at the expense of quality; at ISV, the two go hand-in-hand. “All ISV valves are shipped with the ISV guarantee of high-quality design, materials, and workmanship. ISV’s warranty is 12 months after installation or 18 months after date of shipment, whichever is greater. This is important to ISV and all our customers,” added Olson.

“All product-related services are performed by ISV’s trained valve assembly technicians. This ensures the customer receives a factory direct, knowledgeable, and experienced valve technician that is well versed with ISV products,” stated O’Quinn.

With the recent expansion of its Stafford, Texas facility, the company is also able to provide several added services that elevate it to the next level. “The new addition to our facility means that not only are we able to add welding capabilities to our offering, and expanded capacity, but we also now offer both in-house and external customer training programs in our training center,” explained Olson.

“We pride ourselves on the multifaceted nature of our business,” expressed O’Quinn. “While we are a valve manufacturer, our training center also provides the customer with hands on assembly experience so that they have a better understanding of the parts and features of the valve and consequently a deeper understanding of the assemblies they are working with.” The amalgamation of shop floor and classroom training that ISV offers customers, and employees, provides them with a unique opportunity to learn why certain specifications are required and to recognize how to identify if an application has met those standards. “This adds tremendous value for our clients, as once they go through a thorough training like that, they never forget it.”

Exceeding Expectations

Maintaining a rigorous standard of quality is central to ISV’s approach when it comes to conducting performance and pressure tests on their products. As a minimum, each ISV valve is pressure tested in accordance with the standard for which it is designed. In many cases, O’Quinn notes, the company’s standard test procedures and instructions exceed the industry’s standard product design test requirements. These include, for example, longer test durations than what is required by the industry test standard. “We perform the optional seat test on ball valves as an ISV standard, rather than bypassing it,” explained Olson. “Additionally, we perform PMI (Positive Material Identification) as a standard on all alloy ball valve bodies, end caps and key components.”

O’Quinn further explained that each PMI reading is retained in the company’s data-base and linked to the valve’s serial number for future traceability, while random material verification tests are performed to confirm that purchased component materials meet or exceed the intended material standards. As the company’s testing results are a key part of its quality assurance program, ISV has created a detailed testing report process by compiling each valve’s test data into their extensive data-base. This way, the test reports for each valve purchased by any customer can be provided to the customer upon request.

“ISV had the opportunity to establish our company during a time in which computer technology had already grown from its infancy stages. As such, from day one, we were able to utilize and employ data management technologies starting at the valve component level all the way through a finished valve product.” All ISV valves, including the smallest size of .25”, are serialized — allowing full product traceability for many years beyond the point of its installation in the field.

This traceability incorporates a thorough record of the production process, from original mill test reports for each component, to the name of the employee performing the final inspection. In addition, general assembly drawings are available upon request for all ISV products; for extreme traceability for all records are kept for minimum 10 years. This allows the company to more efficiently communicate to the customer the exact details of the product being offered and considered. In turn, the customer’s review and feedback can help the company to understand any special requirements or features specific to the customer.

Looking Forward

ISV’s every endeavour goes beyond standard procedure; though exemplified through the customer experience, the company’s attention to detail and commitment to service permeates every facet of its inner workings. With equal devotion to the core of its values, the precision of its service, and the quality of its products, International Standard Valve is simultaneously a multi-tasking and laser-focused force.