Hydrogen is increasingly viewed as a critical component for achieving net-zero carbon emission commitments and mitigating human impact on climate change. It is an attractive alternative to traditional fuels due to its high energy content, low emissions, and potential for renewable production.

Net-zero commitments require countries and industries to balance their carbon emissions with carbon removal or offsets, pushing all industrial sectors to reduce greenhouse gas emissions as much as possible.

By Foster Voelker II – Director of Engineering – Williams Valves

According to the United Nations, “More than 70 countries, including the biggest polluters – China, the United States, and the European Union – have set a net-zero target, covering about 76% of global emissions. More than 3,000 businesses and financial institutions are working with the Science-Based Targets Initiative to reduce their emissions in line with climate science. And more than 1,000 cities, over 1,000 educational institutions, and over 400 financial institutions have joined the Race to Zero, pledging to take rigorous, immediate action to halve global emissions by 2030.”1 Hydrogen can play a key role in this effort by providing a clean, efficient, and flexible energy source.

An Energy Carrier

Hydrogen is a secondary source of energy, known as an energy carrier. It stores and transports energy produced from other resources (fossil fuels, water, biomass, etc.). Hydrogen has the potential to decarbonize a range of sectors that are difficult to electrify, such as long-haul transportation and aviation. These sectors are responsible for a significant share of global greenhouse gas emissions, and their decarbonization is crucial to achieving net-zero goals.

However, electrifying these sectors is challenging due to many technical and economic factors, such as the need for large amounts of energy and the lack of suitable charging infrastructure. Hydrogen, on the other hand, can be used as a fuel or feedstock in industrial processes, as well as a fuel for transportation, without the need for a large-scale charging infrastructure. Thus, hydrogen can potentially provide a viable alternative to fossil fuels in sectors where electrification is difficult or not feasible. The implications of this potential are already driving investment.

According to the Hydrogen Council, “Air Liquide and Total Energies announced their decision to create an equally owned joint venture to develop a network of hydrogen stations, geared towards heavy-duty vehicles on major European road corridors. This initiative will help facilitate access to hydrogen, enabling the development of its use for goods transportation and further strengthening the hydrogen sector. The partners aim to deploy more than 100 hydrogen stations on major European roads – in France, Benelux and Germany – in the coming years. These stations, under the Total Energies brand, will be located on major strategic corridors.”2

Significant Potential

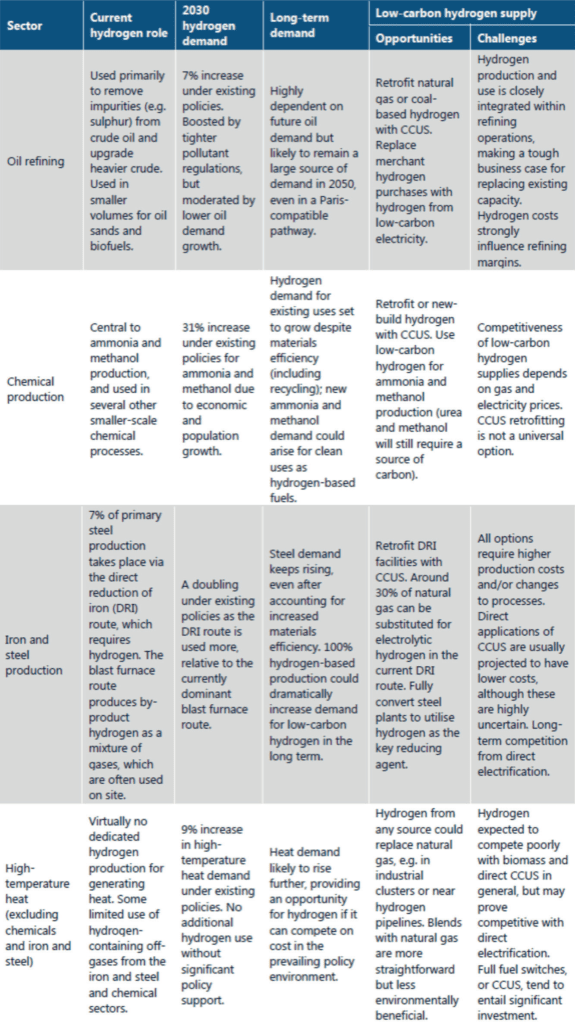

Hydrogen has other potential uses outside of decarbonizing transportation. The International Energy Agency (IEA) prepared an extensive report for the G20 Summit in 2019 titled “The Future of Hydrogen,” which outlines many potential hydrogen applications. The report identifies several areas where hydrogen can play a significant role: power generation, electrical storage, feedstock for industrial processes, fuel for heating buildings, etc. The IEA report highlights the potential for hydrogen to play a significant role in the development of a hydrogen economy, where hydrogen becomes a key energy carrier helping to enable a low carbon system. The report notes that the development of a hydrogen economy will require significant investment and policy support, as well as the development of hydrogen production and distribution infrastructure. Figure 1 provides an overview of the current and likely future industrial uses of hydrogen.3

Common Obstacles

While hydrogen has many potential benefits as an energy carrier, there are also several challenges that need to be addressed to realize its full potential. The largest obstacle prohibiting the adoption of a hydrogen is production cost. Producing hydrogen can be extremely expensive. Electrolysis, the process of splitting water into hydrogen and oxygen, is currently the most common method of producing hydrogen, but it requires a significant amount of energy. The energy can be produced from a variety of sources, including renewable energy, nuclear power, and natural gas with carbon capture and storage (CCS).

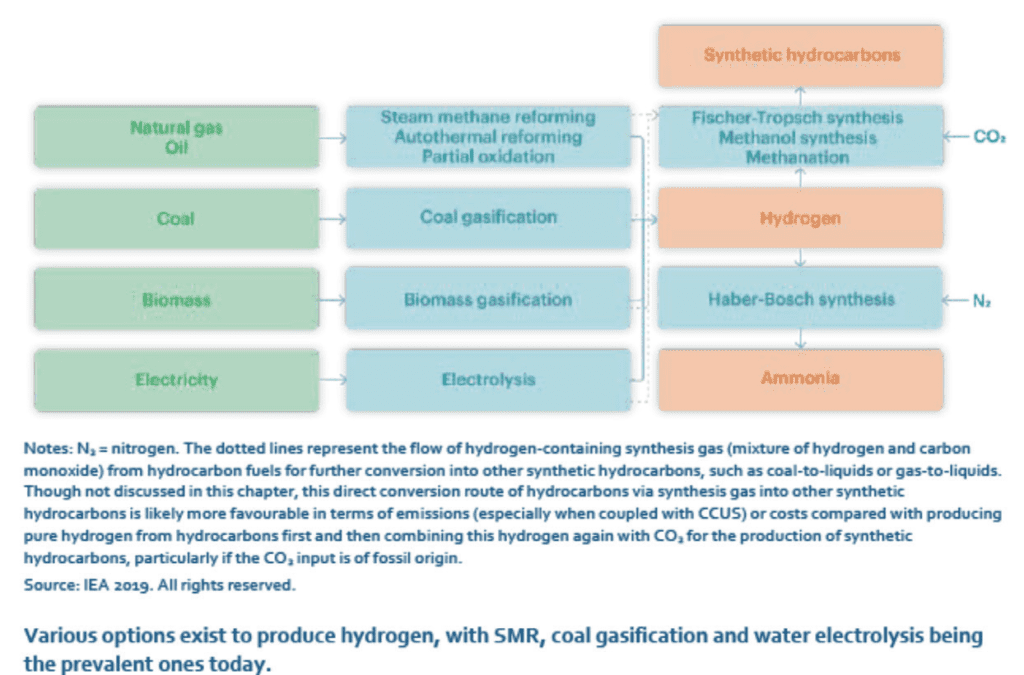

The production of hydrogen from renewable sources, such as wind and solar power, is known as green hydrogen and is considered the most sustainable and environmentally friendly option. Green hydrogen production can help reduce greenhouse gas emissions from the energy sector by decreasing dependency on fossil fuel energy sources. Hydrogen produced from nuclear power or natural gas with CCS is known as blue hydrogen. Figure 2 from the IEA report outlines the various pathways for hydrogen production.

Regardless of production method, the cost of producing hydrogen must be reduced to make it economically viable.

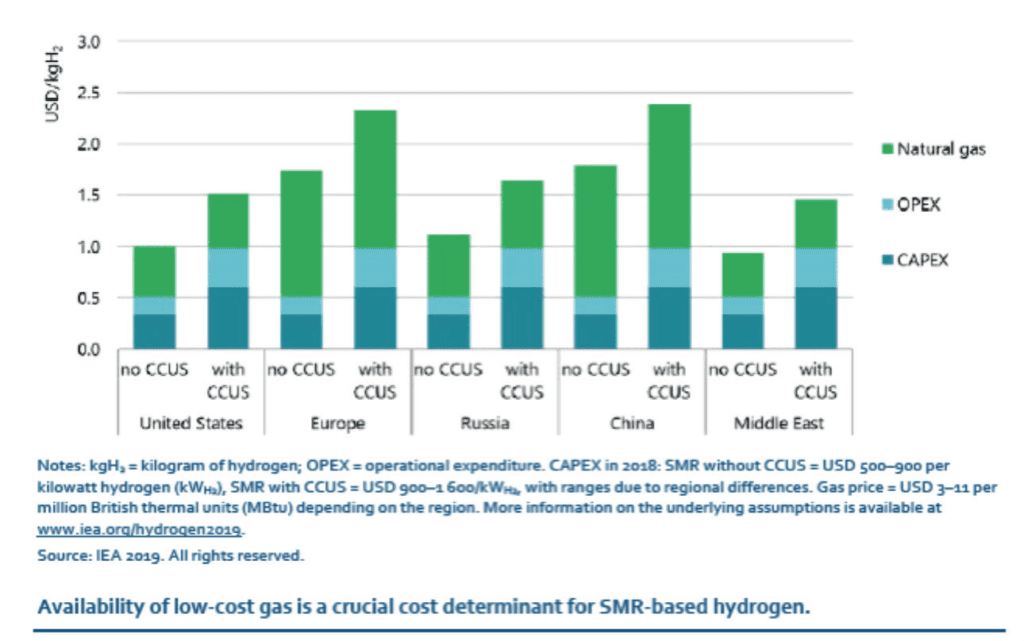

According to the report, “The production cost of hydrogen from natural gas is influenced by various technical and economic factors, with gas prices and capital expenditure (CAPEX) being the two most important. Fuel costs are the largest cost component in all regions and account for between 45% and 75% of production costs (Figure 3). Low gas prices in the Middle East, the Russian Federation, and North America give rise to some of the lowest hydrogen production costs. Gas importers such as Japan, Korea, China and India have to contend with higher gas import prices, and that makes for higher hydrogen production costs.”3 Figure 3 compares, by country, the production costs of hydrogen utilizing natural gas.3

Other challenges include storage, infrastructure, safety, and scalability. Hydrogen is a very light gas that has low energy density, requiring high-pressures or cryogenic temperatures to be stored efficiently. This can make storage and transportation of hydrogen difficult and expensive. Infrastructure must be developed to support the widespread use of hydrogen as an energy source. This includes production facilities, storage facilities, pipelines, or transportation systems, and fueling stations.

Building this infrastructure will require significant investment, raising concerns about the scalability of hydrogen production and use. In addition to these economic challenges, hydrogen is highly flammable and can be difficult to handle safely. Storage and transportation of hydrogen requires specialized equipment and procedures to ensure the safety of personnel and the environment.

Impact on Industry

Regardless of these challenges, Hydrogen is likely to play a key role in achieving the ambitious net-zero goals as it provides a clean, efficient, and flexible energy source that can help decarbonize hard-to-abate sectors, can integrate with renewable energy, supports the development of a circular economy, and reduce greenhouse gas emissions. The development and deployment of hydrogen technologies will be critical to achieving net-zero goals offering many opportunities for equipment manufacturers.

Valves and other equipment used in hydrogen service applications must be designed and constructed to withstand the unique properties and challenges of hydrogen. It is important to consider factors such as pressure and temperature ratings, material compatibility of both metals and soft components, flow conditions, corrosion and embrittlement, hydrogen blistering, and valve design.

With such significant investment into hydrogen systems, there is an increased demand for industry standards and specifications governing said systems. One useful technical resource developed over recent years, is a Technical Report published by the International Organization for Standardization (ISO) titled ISO/TR 15916: basic considerations for the safety of hydrogen systems.

According to the abstract, “SO/TR 15916:2015 provides guidelines for the use of hydrogen in its gaseous and liquid forms as well as its storage in either of these or other forms (hydrides). It identifies the basic safety concerns, hazards and risks, and describes the properties of hydrogen that are relevant to safety. Detailed safety requirements associated with specific hydrogen applications are treated in separate international standards.”4

ISO/TR 15916 is essentially a reference providing guidelines for the safe and efficient use of hydrogen in the relatively new hydrogen energy applications covering topics ranging from basic Hydrogen properties to mitigation and control risks. ISO is not the only organization focusing on the development of hydrogen standards.

According to a paper published by the 2020 5th International Conference on Advances in Energy and Environment Research, “Hydrogen storage and transportation are the intermediate link of hydrogen production and the point of enduse. Standards for hydrogen storage and transportation published by ISO, CGA, NFPA, ASME, ANSI, SAC, CEN and JISC cover general design and safety, receptacles, piping and pipelines, hydrogen embrittlement, etc. Numbers of standards for hydrogen embrittlement are more than the others. Standards for hydrogen piping and pipelines are only published by CGA and ASME. Chinese GB standards are mainly focused on general design and safety, gaseous hydrogen receptacles and hydrogen embrittlement. Standards for liquid hydrogen storage receptacles and safety, hydrogen piping and pipelines, and hydrogen transportation should be emphasized.”5

Thus, the valve industry is likely to see an increase in the development of industry standards and user defined requirements to address hydrogen applications.

REFERENCES

- https://www.un.org/en/climatechange/net-zero-coalition

- https://hydrogencouncil.com/en/air-liquide-andtotalenergies- join-forces-to-create-a-europeannetwork- of-hydrogen-stations/

- https://iea.blob.core.windows.net/assets/9e3a3493-b9a6- 4b7d-b499-7ca48e357561/The_Future_of_Hydrogen.pdf

- https://www.iso.org/standard/56546.html

- https://www.e3sconferences.org/articles/e3sconf/abs/2020/54/e3sconf_icaeer2020_02018/e3sconf_ icaeer2020_02018.htm