Offshore platforms are essential to the energy sector, facilitating oil and gas extraction and transportation. As the need for cleaner energy and improved efficiency grows, the limitations of traditional valve systems have become evident.

These conventional systems often take up valuable space and add unnecessary weight to offshore structures. Modern valve technologies, such as pig ball valves and wafer monoblock valves, offer considerable improvements in optimizing space, reducing weight and enhancing operational efficiency.

By Zahra Farrokhi, Batu Valve Türkiye

1. Challenges of Traditional Valve Systems in Offshore Platforms

While traditional valve systems have proven reliable, they present challenges when used on offshore platforms.

Weight and Space Constraints

Traditional valve systems are bulky, comprising of multiple components such as pig launchers, receivers and piping. These systems consume significant space on offshore platforms, contributing to the overall weight, which can affect structural integrity and increase maintenance costs.

As offshore operations demand more efficient designs, reducing the space required for valve systems has become crucial (Smith & Jones, 2023) (Garcia & Martinez, 2024).

Maintenance and Durability Issues

Older valve systems are prone to wear and corrosion due to the harsh offshore environment, leading to frequent maintenance and system downtime. This results in costly repairs and reduces operational efficiency (Evans & Brown, 2023). Furthermore, constant repairs and replacements contribute to the environmental footprint of offshore operations (Garcia & Martinez, 2024).

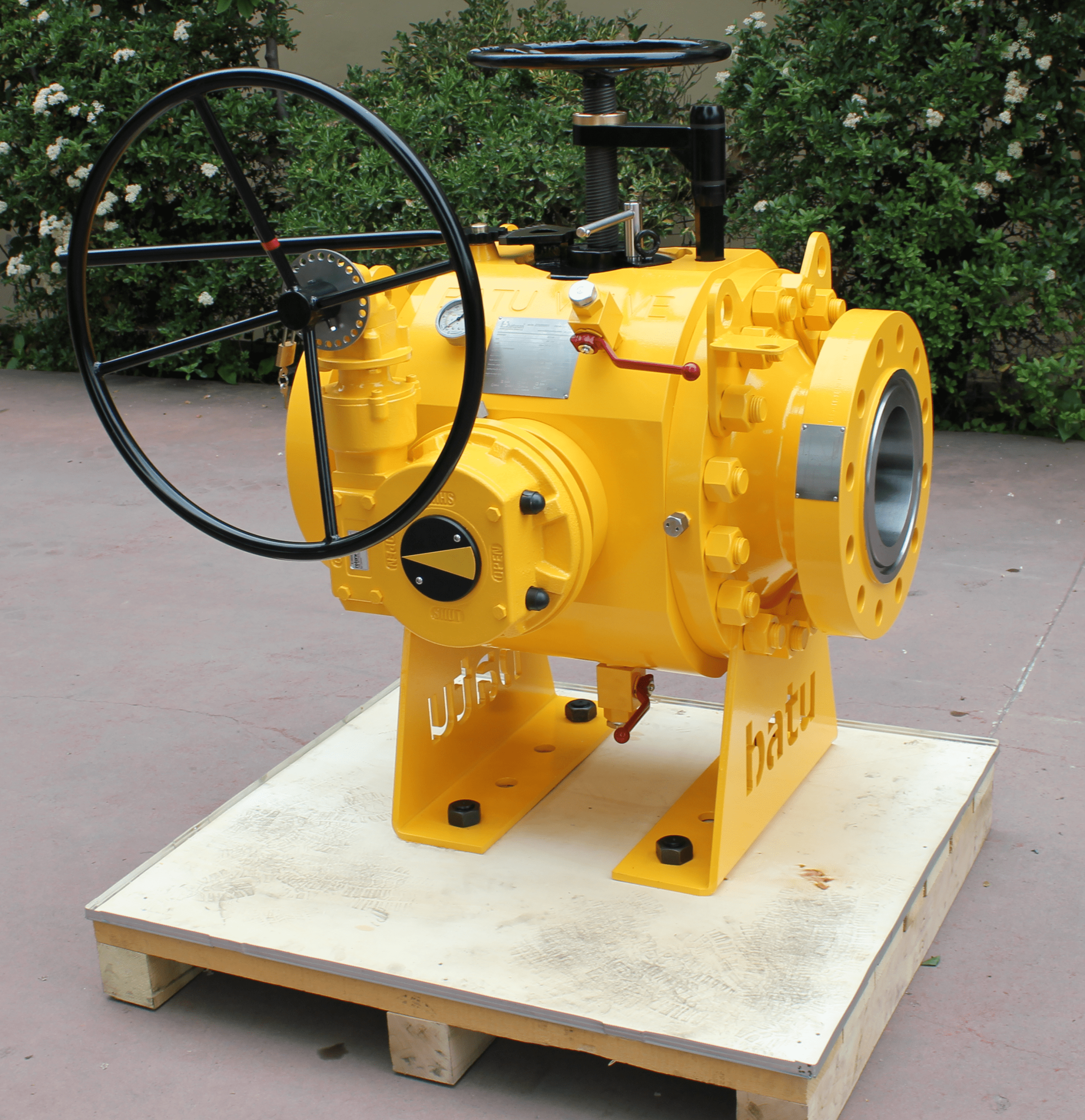

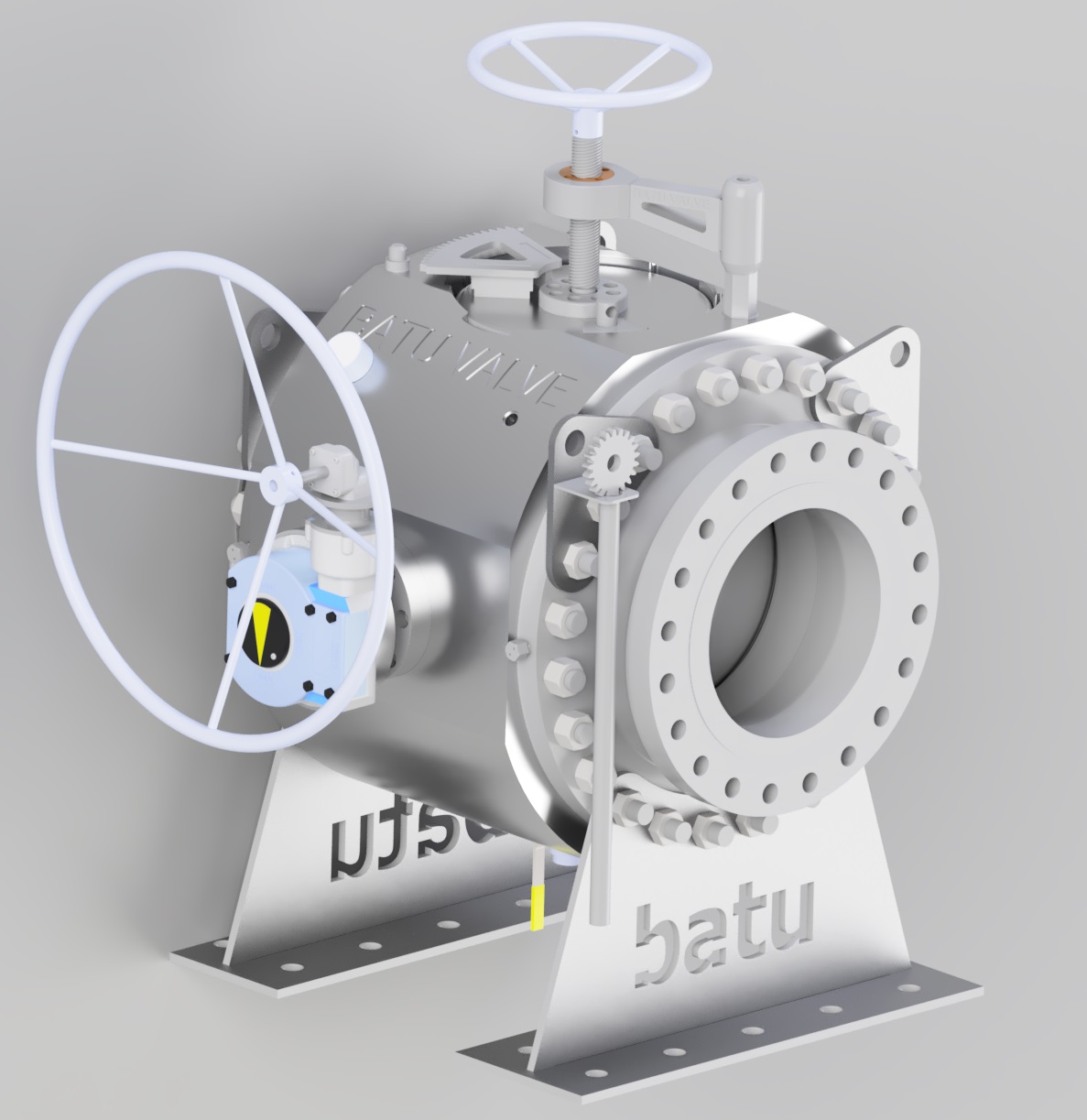

Figure 1. 3D design and model of illustrated pig ball valve in the Vietnam Offshore Project.

2. Defining Pig Ball Valves and Wafer Monoblock Valves

Understanding the innovations offered by pig ball valves and wafer monoblock valves is essential to appreciating their benefits in offshore operations.

Pig ball valves:

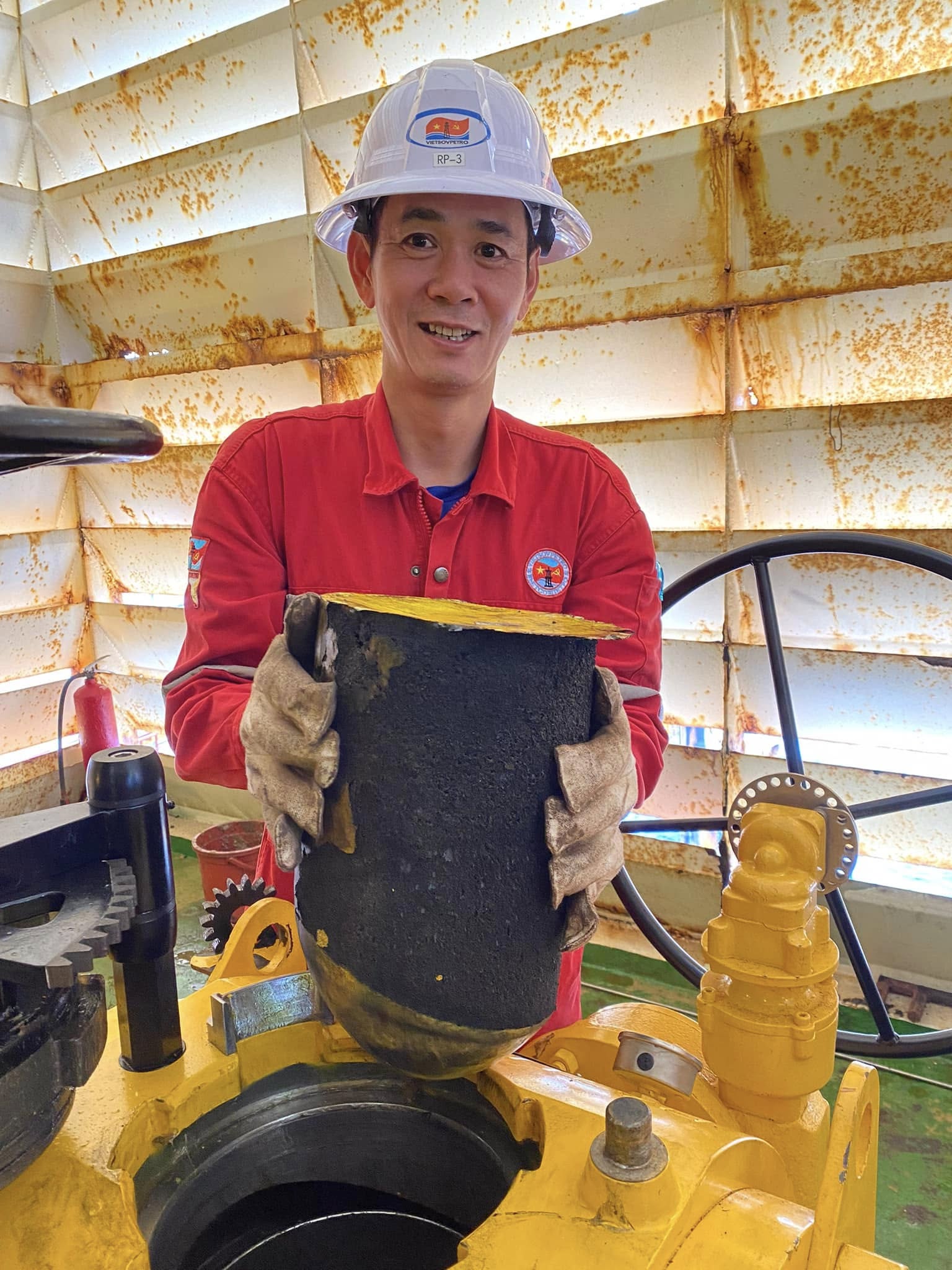

Pig ball valves are used in pigging operations, which is essential for cleaning and inspecting pipelines without removing the valve. These valves streamline the process by combining multiple components into a single unit, optimizing space and reducing weight (Harris & White, 2023).

Wafer monoblock valves:

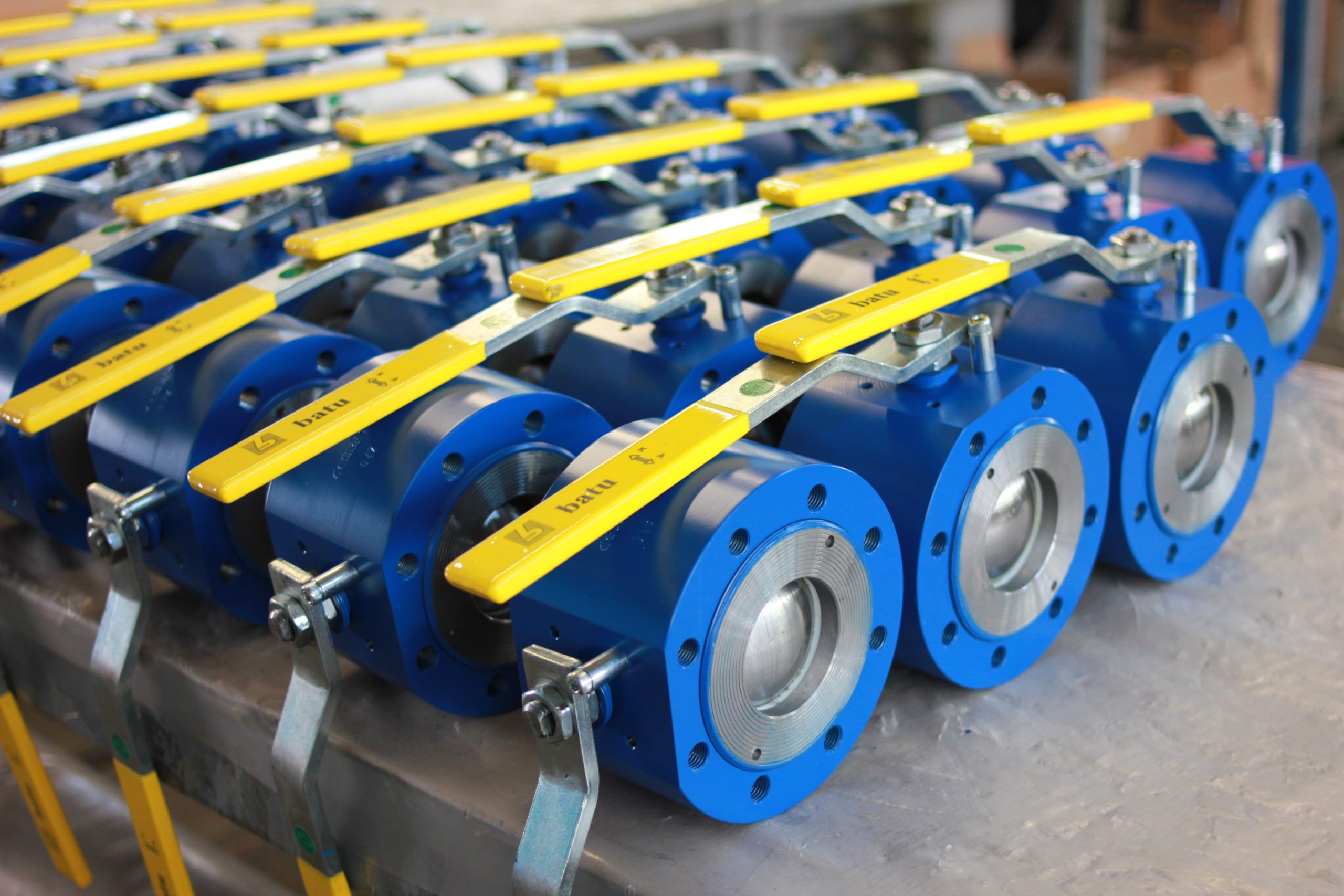

Wafer monoblock valves feature a single-piece design that reduce the number of components, lowering both the weight and space requirements. This type of valve fits seamlessly between two flanges, simplifying installation and ensuring enhanced reliability due to fewer potential leak points (Zhang & Li, 2024).

Figure 2. Wafer monoblock ball valves: space-saving and efficient solution for offshore operations.

3. Why Offshore Platforms Need Pig Ball and Wafer Monoblock Ball Valves

As offshore operations evolve, valve technologies that offer improved efficiency, reduced weight and minimal space usage are increasingly essential. Pig ball valves and wafer monoblock valves are designed to meet these needs, offering numerous advantages over traditional valve systems.

Traditional valve systems require multiple components, such as launchers and receivers, which consume significant space and increase the platform’s weight. Pig ball valves integrate the functions of these components into a single unit, reducing both space and weight (Smith & Jones, 2023). Wafer monoblock valves are made from a single piece of material, resulting in smaller, lighter valves, critical in space-constrained offshore environments (Zhang & Li, 2024; Garcia & Martinez, 2024; Zhang & Li, 2024).

4. Reduced Weight and Space Usage

Both pig ball valves and wafer monoblock valves stand out due to their significant reductions in weight and space usage, which are vital in offshore applications.

Pig ball valves:

- Compact design: The integrated design eliminates the need for separate pig launchers, receivers, and piping (Harris & White, 2023).

- Space optimization: By reducing the number of components, pig ball valves occupy less space, which is crucial for offshore operations (Garcia & Martinez, 2024).

Wafer monoblock valves:

- Monoblock construction: The single-piece design of wafer monoblock valves reduces the number of components, thus reducing both space and weight requirements (Zhang & Li, 2024).

- Simplified integration: The compact design allows for easier integration into existing systems, which reduces installation time (Chen & Zhao, 2024).

5. Lower Costs and Cost-Effectiveness

Both valve types offer significant cost-saving advantages over traditional valve systems.

Pig ball valves:

- Lower initial and operational costs: The reduced number of components simplifies installation and lowers upfront costs. Maintenance savings are also notable, with pig ball valves requiring less maintenance than traditional systems (Harris & White, 2023).

- Statistical data: Pig ball valves reduce installation costs by 15% and operational costs by 20% over their lifecycle (Garcia & Martinez, 2024).

Wafer monoblock valves:

- Material savings: Wafer monoblock valves use less material due to their monoblock design, lowering manufacturing and material costs (Zhang Li, 2024).

- Lower lifecycle costs: Despite a higher initial cost, the durability of wafer monoblock valves and their reduced maintenance needs lead to lower lifecycle costs (Chen & Zhao, 2024).

Vietsovpetro Offshore Platform technician demonstrating the use of advanced pig ball valve technology, replacing traditional pigging systems for improved efficiency and space optimization.

6. Simplified Installation

Both pig ball valves and wafer monoblock valves simplify the installation process, resulting in significant savings in time and labor.

Pig ball valves:

- Streamlined design: The integrated design reduces installation complexity, saving time and costs (Harris & White, 2023).

- Faster setup: With fewer components to install, the setup is quicker, allowing offshore platforms to resume operations faster (Evans & Brown, 2023).

Wafer monoblock valves:

- Ease of deployment: The single-piece design of wafer monoblock valves eliminates the need for multiple connections, leading to faster and simpler installation (Zhang & Li, 2024).

- Seamless integration: Their compact nature also simplifies integration into existing systems, speeding up the overall installation process (Chen & Zhao, 2024).

7. Improved Efficiency

Both pig ball valves and wafer monoblock valves contribute to improved efficiency in offshore operations by optimising pipeline maintenance and enhancing flow control.

Pig ball valves:

- Enhanced pipeline efficiency: The streamlined pigging process with pig ball valves reduces downtime and enhances pipeline maintenance (Chen & Zhao, 2024).

- Improved flow control: Pig ball valves provide better flow control, ensuring smoother pipeline operations with minimal disruptions (Evans & Brown, 2023).

Wafer monoblock valves:

- Optimized flow: The excellent sealing and flow control capabilities of wafer monoblock valves minimize resistance and optimize flow efficiency (Zhang & Li, 2024).

- Increased reliability: Their robust design enhances reliability, ensuring uninterrupted operations on offshore platforms (Chen & Zhao, 2024).

8. Sustainability and Environmental Concerns

Both pig ball valves and wafer monoblock valves provide substantial environmental benefits, contributing to sustainable offshore operations.

Pig ball valves:

- Leakage reduction: The advanced sealing technology reduces the potential for leaks, crucial for minimising emissions in offshore environments (Jansen & Muller, 2023).

- Energy efficiency: The optimized flow provided by pig ball valves helps reduce friction, lowering energy consumption (Smith & Jones, 2023).

Wafer monoblock valves:

- Material sustainability: The use of durable materials in wafer monoblock valves extends their lifespan, which reduces the need for frequent replacements and minimizing waste (Zhang & Li, 2024).

- Reduced carbon footprint: The reduction in material waste and maintenance requirements helps wafer monoblock valves contribute to a lower carbon footprint (Chen & Zhao, 2024).

Conclusion

The integration of pig ball valves and wafer monoblock valves into offshore operations provides a clear path toward optimizing space, reducing weight and improving operational efficiency. These modern valve technologies address the challenges posed by traditional systems and offer significant advantages in terms of cost, installation, sustainability and reliability.

As offshore platforms continue to evolve, the adoption of these advanced valve solutions will play a pivotal role in meeting the growing demands of the energy sector while minimizing environmental impact.