Located in Houston, Texas, Franklin Valve prides itself on its manufacturing capabilities that put the client’s needs at the forefront. Its innovative flow control technology is designed, assembled, and tested in-house and offers the highest value in product quality. Additionally, Franklin Valve offers top-of-the-line repair and maintenance services for their products, positioning the company to excel in the valve community as a respected and valued valve OEM.

Valve World Americas had the pleasure of speaking with Dustin Thompson, Engineering Manager at Franklin Valve, about its rich evolution and journey to where Franklin Valve is today, its innovative new product line, and what lies ahead for the company.

By Charlie Evans

2000s, Franklin Valve & Supply began as a double block and bleed repair shop for general twin seal valves. In 2005, Franklin Valve & Supply set its sights on bigger goals, aiming to evolve beyond a valve repair shop. Renamed Franklin Valve LP and purchased by current owner and CEO John Brennan, the company transitioned into designing and producing its own valves. “2006 was the start of Franklin Valve LP as a valve OEM,” said Thompson. “In 2007, we progressed further and received our API 6D monogram; the governing specification we use for our heritage plug valve and our symmetrical compact expanding gate valve.”

Receiving the API 6D monogram was a large milestone in Franklin Valve’s development. “It speaks to the quality of our product and organization,” continued Thompson. API audits all design files to ensure they comply with the specifications of 6D, as well as operating procedures for compliance to API Q1. This allows Franklin Valve to apply the API 6D monogram onto their products. “Even after achieving the monogram license, constant product and process improvement has been a shared goal for our team.”

2009 was a brand relaunch for the company. “The company achieved significant growth from 2009 to 2016 in both product offering and market reach. The existing product lines expanded into larger sizes and higher ANSI classes. We started primarily with 150 class plug valves but by 2016, we had expanded into the 300, 600, and 900 classes as well. To complement this, we also launched a full bore line and the 4-WAY diverter valve.” In 2014 the company moved into a larger facility, increasing both its quality and engineering departments to support growth.

Driven by continued growth, Franklin Valve expanded its facility again with an additional 45,000 square feet to its existing 65,000 square feet in 2019. “This enabled us to expand our inventory and quality departments even further as well as allowing for the addition of a new assembly cell to support the newest addition to the product line, the DuraGate™ Symmetrical Expanding Gate Valve.”

From 2020 onwards, it was all about continued expansion and growth. “We want to continue with our growing success on all fronts. To that end we have several exciting projects currently in the works.”

“We greatly value our personnel and customers and do our best to maintain close-knit relationships which allows for a more familial atmosphere. We do not just sell valves, we build partnerships.”

An Emphasis on Quality

Franklin Valve has always placed a focus on quality. “It is very important to us to be synonymous with quality.” From the outset, Franklin Valve showed its prioritization of quality by qualifying its operational procedures to both ISO 9001 and API Q1 standards. “In 2016 we furthered our quality by converting our paper-based quality management system into a state- of-the-art, web-based interactive system.” Franklin Valve’s online Quality Management System is publicly available on its website, ensuring proper document revision control, supporting robust company training, and allowing for seamless customer and regulatory audits.

Service and Availability

“We hold a fair amount of strategic inventory, so our lead times in comparison to our competitors are unmatched,” said Thompson. “We can maintain an on-time delivery of around 99% while delivering products with the highest quality. From this perspective, we are leaders in the industry.” Franklin Valve also prides itself on their ability to effectively leverage lean principles in tandem with their strategic inventory in an effort to ensure availability of high-integrity products while maximizing efficiency. “Our production processes were designed with lean manufacturing in mind, optimizing the utilization of our facility and personnel.”

Despite their continued growth, Franklin Valve maintains the internal agility and customer-centric focus of a smaller company. “We greatly value our personnel and customers and do our best to maintain close-knit relationships which allows for a more familial atmosphere. We do not just sell valves, we build partnerships.”

“Our flat organizational structure empowers our teams to act swiftly. Take our sales team, for example. They consistently turn around most customer inquiries within 24 hours. This agility is fueled by their ability to collaborate seamlessly across departments and leverage the expertise of our talented salesforce,” continued Thompson.

Franklin Valve also prides itself on after-market support and customer service. Its online Quality Management System is home to a wide variety of video service and troubleshooting tutorials available to all end users, and service technicians are available to be onsite whenever required.

Strength in Product Innovation

DuraSeal™ Double Block & Bleed Plug Valve

“The DuraSeal™ plug valve is our heritage product. It is where we got our start,” said Thompson. The DuraSeal™ is a double block and bleed plug valve for critical isolation applications. After reaching and completing hydrostatic testing, each valve receives an API monogrammed nameplate, signifying it has met all design, process, and quality requirements. “Unlike other valve types, the acceptance criteria for our products is zero leakage per API SPEC 6D,” explained Thompson. “Additionally, many manufacturers do batch testing, where they make ten valves and only test a percentage of that lot. If we make ten valves, we test ten valves. Therefore, customers are assured that they will get a good product.”

The DuraSeal™ provides the confidence of a time-tested design bolstered through years of continuous optimization. “Internal quality metrics alongside valuable customer feedback provide the basis for continuous product improvement in our efforts to deliver the most robust isolation solution available.” Another highlight of the plug valve is its inline maintenance ability. “If you were to damage a slip seal on our product, repairs can be done in- line. The ease of repairability has made this product style a popular choice with end users who do not have the luxury of long repair downtime.”

DuraSeal™ 4-Way Diverter Valve

Released in 2015, the DuraSeal™ 4-Way Diverter Valve plays a pivotal role in the midstream world. “It was brought on as a complementing product line to the plug valve design,” said Thompson. One of the common applications for the DuraSeal™ plug valve is on metering skids, where it provides critical isolation during meter proves. These metering skids measure product volume through a pipeline when changing custody. “It effectively acts as the cash register of the pipeline,” said Thompson. One of the predominant ways to prove the ongoing accuracy of the meter is with a bi-directional prover. “You can think of it as a calibration tool for the meter.

At the heart of the prover is the 4-Way Diverter Valve.” Part of the criticality of the prover is being able to isolate the flow. “With bubble tight seals, 100% of the flow is making it through the 4-Way valve and into the prover loop, ensuring the full fluid volume is accounted for,” said Thompson.

A mechanically seated expanding valve, like the DuraSeal™ Plug Valve, the 4-Way has a zero-friction seal and zero leakage. “This valve goes through all the same quality and testing processes as our other products to ensure the best possible outcome for our end users.” Additionally, old or damaged seat seals can be easily replaced in the field.

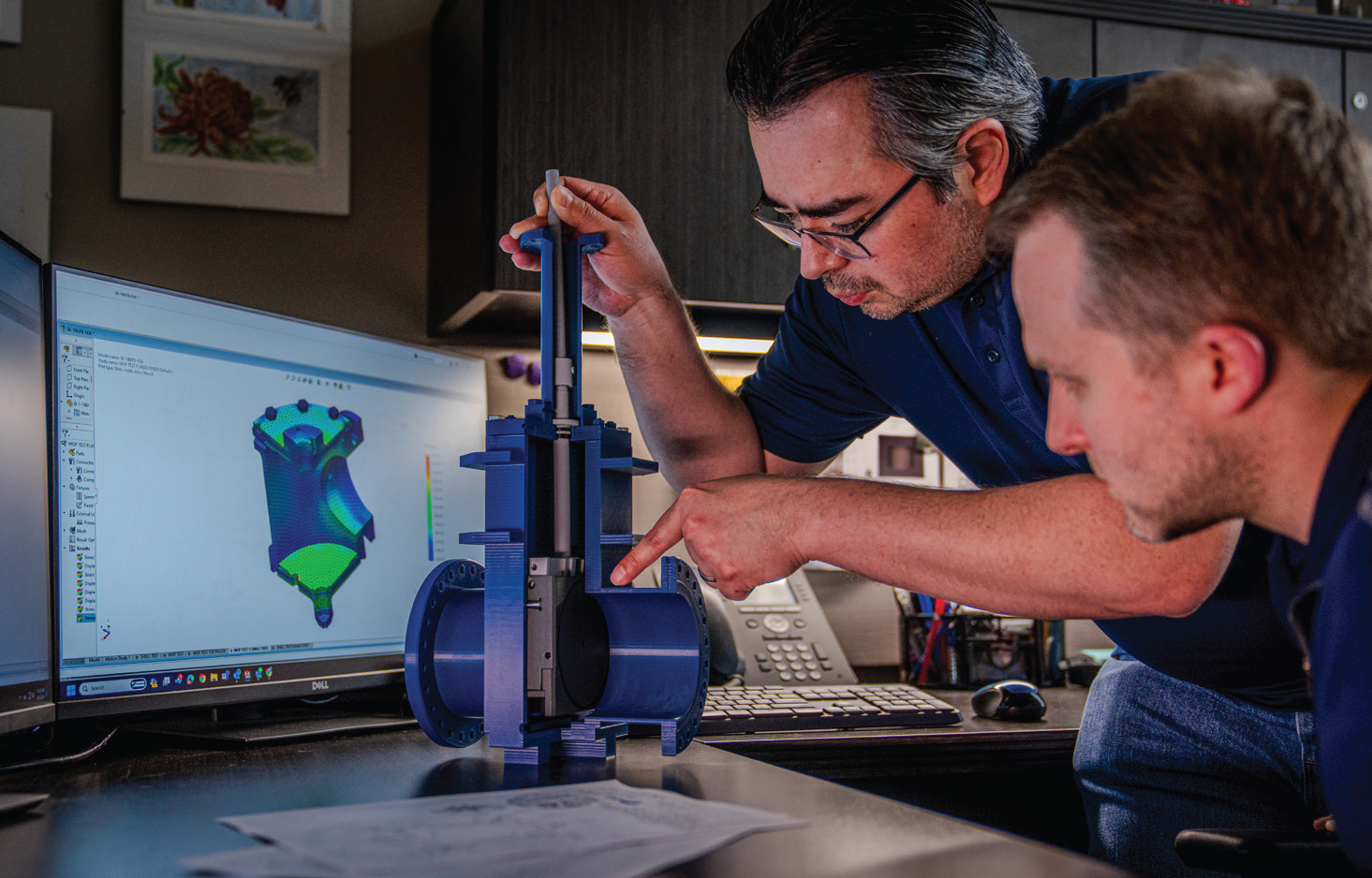

DuraGate™ Symmetrical Expanding Gate Valve

“The DuraGate™ is the latest addition to our product offering. Wasting no time after the 4-Way’s 2015 launch, our R&D department dove headfirst into developing the next breakthrough product,” relayed Thompson. “It works similarly to our other products; mechanically seated with an expanding dual seat design.

However, being a compact expanding gate valve, allows us to target untapped market space in larger NPS applications.” Unlike full size expanding gate valves or larger NPS DuraSeal™ plug valves, the DuraGate™ is compact in the sense that it is a shorter valve and can fit comfortably into smaller locations such as terminal manifolds and skids where space can be limited.

Previously, there was only one player in this product market. “We identify areas of opportunity in the design and set out to create a better solution from the ground up,” relayed Thompson. The valve has a symmetrical internal design, meaning that no matter what direction the fl ow occurs, the valve characteristics remain the same.

“We believe we have greatly improved the inline maintenance ability of this product type, bringing it to a whole new level,” said Thompson. “Listening to end users, we learned that when damaged, most existing products in this market space had to be pulled from line and brought to a repair center for service due to the difficulty of in-field repairs. This results in costly downtime. We took this as a major design consideration when conceptualizing this new product. The new design allows for seat seals to be replaced in the field much like the DuraSeal™ before it.”

Internal quality metrics alongside valuable customer feedback provide the basis for continuous product improvement in our efforts to deliver the most robust isolation solution available.

Looking to the Future

As of now, Franklin Valve has some exciting projects in development. “I cannot say too much at this point in time, however, we are currently working on a number of patented innovations. So, stay tuned, we cannot wait to share these with our partners and customers in the near future!”

The plan moving forward for Franklin Valve is continued growth. “We want to maintain our current upward momentum. We’ll achieve this by actively exploring new product opportunities and deepening our customer relationships,” concluded Thompson.