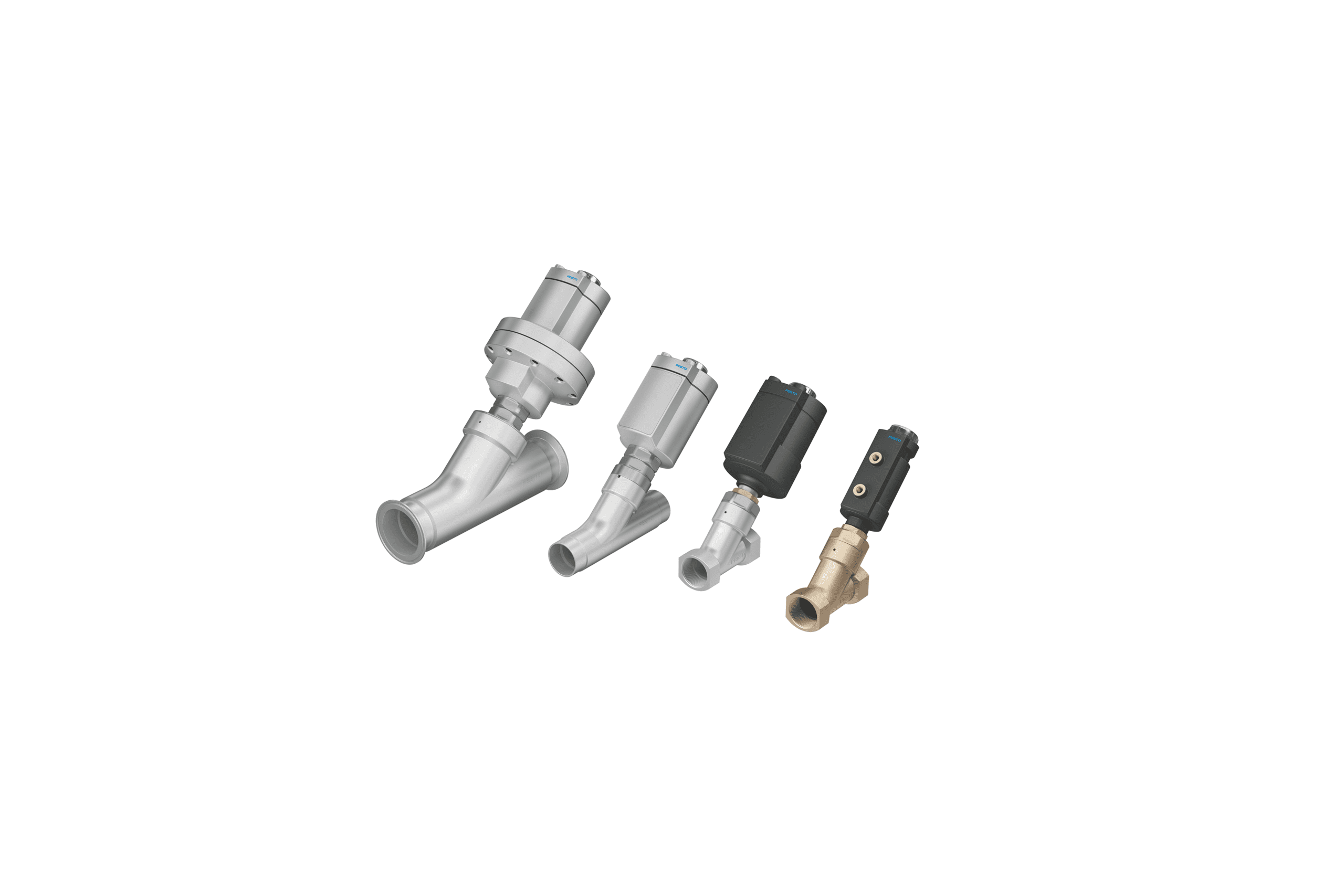

Flexible, robust and offering high performance – the angle seat valve VZXA from Festo controls media flows quickly and reliably up to 230 °C. Its carefully thought-out product design and patented interface enable valve bodies and actuators to be freely combined, with a hot-swap function for quickly exchanging actuator or other spare parts.

Different actuators and valve bodies can be combined for easy integration into the application. Individual, function-tested modules simplify the replacement of actuators during conversion or maintenance. The patented sealing system ensures it is both leak-proof and durable.

Simple installation

The unique interface between the modules means that the actuators can be replaced without opening the piping. The simple separation of valve bodies and actuators makes it easier and faster to install the valves in pipelines. As a result, in areas that are hard to access, the actuators can be mounted on the valve body at the end of an assembly task.

The spindle seal is in the form of a cartridge. It comprises a stainless-steel sleeve with a preloaded chevron packing seal and can therefore be replaced simply and reliably without the need for a special-purpose tool.

Sturdy materials

The angle seat valve VZXA comprises an angle seat valve body, a piston or diaphragm drive and a visual position indicator. The flow-optimised valve body made of stainless steel is available in the nominal widths DN15 – DN65. The variant with threaded connection is available; clamp connections and weld-ends in accordance with American and European standards are planned.

The stainless-steel actuator is available in three sizes and with the control functions NC (normally closed), NO (normally open) and DA (double-acting). The maximum operating pressure, depending on nominal width, is up to 30 bar. The large visual position indicator is fitted as standard. Thanks to the transparent cover made of polyethersulfone (PES), using the valve in chemically aggressive environments does not pose a problem.

Courtesy of Festo.