Valve Innovation Within Power Plants

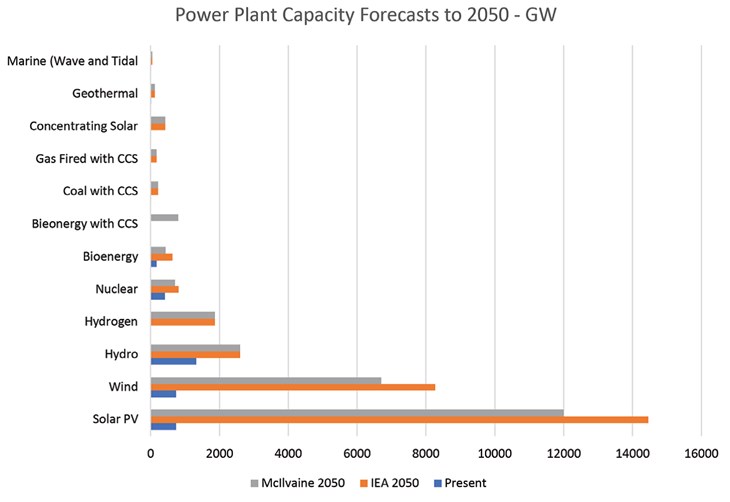

Already, valves are vital within the power industry, but the valve purchases for a wind or solar plant are smaller than those required for a coal plant. Since the projected capacity for wind and solar is large and the projected capacity additions for coal and nuclear plants are modest, it seems logical that the market for power plant valves would be unattractive compared to other market opportunities – but this is not the case.

Valve Innovation

The technologies necessary to provide high-capacity factor electricity for this geo-engineering technique however, requires lots of valves. Although this is true of a number of diverse power technologies, BECCS and hydrogen require more valves than other power generation options. This is illustrated on a comparison per kW, see Figure 2.

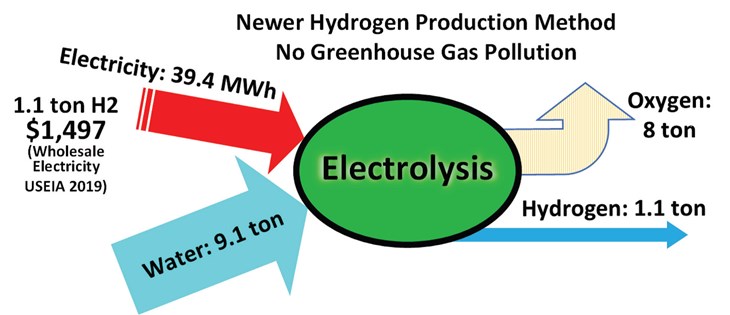

As blue hydrogen, which is derived from methane in natural gas, requires ample valves because energy is created from processes which generate CO2, carbon capture and storage (CCS) is necessary.

Hydrogen is colorless, odorless, and highly explosive. It also has low viscosity, low molecular weight, and is an asphyxiant. These characteristics make zero leakage a necessity. Leakage must be addressed not only at the seat but also at all other components. Metal gaskets, which require more accurate and precise machining, can be useful when temperature requirements limit the use of soft materials. Packing design also becomes critical to avoid stem leakage. Additional inspection practices such as radiography may be necessary as well.

The wood pellets are then shipped to a power plant where they substitute for coal as the fuel. If it is a coal-fired plant, such as Drax in North Yorkshire, England, there are several types of valves essential to energy production. This includes valves used to manage the boiler feed, water intake, and cooling processes. Within BECCS power technology, valves are also used to control air and water pollution, including in the flue-gas desulfurization (FGD) systems. Additionally, carbon capture technology utilizes another set of valves for the amine absorber, which absorbs hydrogen sulfide and carbon dioxide to convert sour gas into sweetened gas.

Once captured, the CO2 must be transported to a permanent storage site. Currently, the most economical method for transporting large volumes of CO2 is via pipeline. To make this possible, the CO2 is converted into a high-pressure, supercritical fluid called dense phase. In this phase the CO2 behaves more like a liquid than a gas, allowing it to be pumped. Several valves are required with each pump.

The Advantages of BECCS

Regardless of the method, BECCS has a number of advantages. The most obvious is that it is carbon negative. If all coalfired plants in the world were converted to BECCS global CO2 levels could be reduced. This option eliminates the tipping point worry.

The tipping point worry phenomena occurs when global temperatures exceed a critical threshold, causing advanced and irreversible environmental damage.

Another advantage is the cost. The only other carbon negative technology is Direct Air Capture. The cost of this option, however, is quite high. BECCS, on the other hand, can utilize existing coal plant steam generators and pollution control systems. The major capital cost is in the actual carbon capture and sequestration process.

The biggest advantage of BECCS is the potential use of a staged approach; the easy, slow implementation of BECCS processes in existing coal plants. The steps to implement BECCS are as follows:

Stage 1: Co-firing biomass at existing coal plants.

Stage 2: Complete conversion to biomass.

Stage 3: Partial carbon capture and sequestration or usage.

Stage 4: Full carbon capture and sequestration or usage.

The Drax power plant in the UK is already moving from stage to stage. Although they are currently at stage two, engineering and construction is underway for stage three.