As a part of the declaration, the City developed a multi-departmental Corporate Climate Change Task Force with the main directive to investigate and identify actions that need to be taken to achieve net zero carbon emissions before 2050. The City’s climate change emergency offers nine climate change goals, which focus on infrastructure, transportation, the environment, and the way the City does business.

By Peter Sucharda, President – Devine & Associates & Mark Gimson, Director of Marketing & International Sales – Cla-Val Company. Posted by Sarah Bradley.

Hamilton Water, which is a key stake-holder on the Corporate Climate Change Task Force, is one of the largest energy users in the city. In 2019, Hamilton Water spent more than CDN $13 million on power costs amounting to about 6% of the annual budget. The city’s water distribution system is one of the oldest and most complex in Canada. It includes six water distribution systems, 1,262 miles of watermains and 144,691 water service connections. It has an elevation of 298 ft (91m) above sea level and is defined by unique geographical features like the Niagara Escarpment and Hamilton Harbor.

Maintaining a consistent operating pressure is a difficult undertaking due to the Niagara Escarpment. This steep rock face that runs through the middle of the city across its entire breadth, bisects the city into ‘upper’ and ‘lower’ sections. This vertical wall ascends an average of 328 feet and presents a unique challenge in the conveyance of water at acceptable flows and pressures. The city’s distribution system must maintain a minimum operating pressure of 20 psi at ground level at all points under maximum day demand plus fire flow conditions. The normal operating pressure within the network is 40 to 100psi. There are 145 pressure district level valves within the City of Hamilton water distribution system.

Due to this elevation change coupled with the sprawling geography of the city, the water distribution system is divided into 24 distinct pressure districts, both open and closed. In an open district, continuous pumping is not required to maintain pressure due to the provision of floating storage, such as an elevated tank or reservoir. In a closed district, continuous pumping is required to ensure that the required flows and pressures in that portion of the distribution network are met.

In areas where a facility such as a reservoir or elevated tank is not present, pumping station discharge head must be enough to overcome system losses and to maintain the appropriate hydraulic gradient. The placement of floating storage within the distribution system not only provides sufficient amounts of water to equalize demand, but also translates into energy savings when supplying the network via gravity.

The various pressure district zones are interconnected via level valves and an open ¾ or 1” (20mm or 25 mm) bypass line. Typically, bypass lines allow a continuous flow of water from the high to low pressure zones to provide a mixing of water to maintain acceptable residual chlorine levels. These by-passing flows consume significant pumping energy. Dave Alberton, Manager of Water Distribution & Wastewater Collection for Hamilton Water said, “Bypass lines are installed to minimize stagnant water issues at dead-ends of the water distribution system and will eliminate customer complaints. By installing the bypass lines, we solved the water quality issue but there was a cost to that continual water flowing through the line and there was no way of measuring it.”

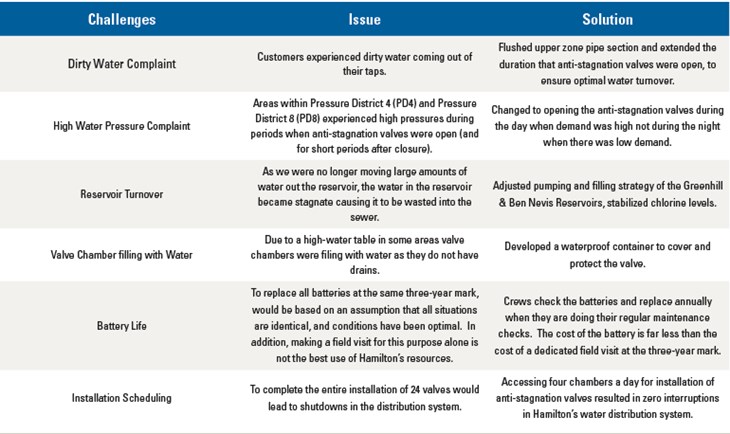

Recently Hamilton’s Water Distribution & Wastewater Collection department completed a pilot project to support the climate change initiative by reducing water loss and electricity consumption. The purpose of the pilot project was to review and investigate the significant increase in flow from two reservoirs (in Pressure Zone District 4 and 8), in comparison to the trends from previous years. This was largely due to bypass lines that were installed around normally closed boundary valves in order to keep the water fresh with a continual flow. This created three issues:

- Over-pressurization of the lower zones during periods of low demand (night-time)

- Higher pumping costs

- Difficulty in modelling systems because there was a great deal of water flowing through the bypass lines that was unaccounted for

Some municipalities have tried to limit the flow through bypass lines by either throttling valves (setting them partially open) or installing a flow-limiting orifice. This inevitably causes problems because valves are not designed for throttling purposes, so it often leads to cavitation and wearing out of the valve seat. Flow limiting orifices frequently wear out for the same reasons. Also, mini breaks occur within the chamber due to cavitation and high flow velocities that wear out the bypass line piping and fittings. The City put out a tender to engineering firms which was won by Devine & Associates. “Upon further investigation with our engineering firm, we determined that it was possible to significantly reduce water flow through the bypass lines from a 24/7 continuous flow to approximately 15 minutes per day, and still maintain water quality, by using a timer controlled anti-stagnation valve. This also significantly reduced the required water flow from pumping stations which lead to a trickle down of many cost savings,” said Alberton.

“One issue we were having with fully-open bypass valves was noise complaints,” said Alberton. As water was passing through the bypass piping at high velocity it would create a loud noise, so the City closed the bypass lines to minimize noise complaints. Closing the bypass lines stopped the noise complaints but allowed stagnant water problems to occur. “By installing anti-stagnation valves, flow through the bypass lines could be limited to short durations at specific times during the day. Typically, our anti-stagnation valves are scheduled to open mid-morning for 15 minutes. At that time many people are away or busy and there is ambient noise. Previously, noise complaints were often made at night or in the early evening. Anti-stagnation valves provide the flexibility to limit resulting noise to times that are more acceptable to residents,” concluded Alberton.

Before the installation of the anti-stag-nation valves, the City inspected and cleaned all 37 valve chambers. All bypass lines were closed for 48 hours resulting in a 35 % flow reduction leaving Greenhill Station in Pressure District 4 (5.28 MGD down to 3.43 MGD) and 77% (0.79 MGD down to 0.158 MGD) leaving Dewitt/Ben Nevis station in Pressure District 8. “This shutdown was done to prove that closing the 37 valves decreased the flow out of the two reservoirs. We also had no pressure or water quality complaints and no service interruptions,” said Alberton.

The anti-stagnation valve is a simple hydraulic control valve that is opened and closed by actuating a latching solenoid on or off. The solenoid changes state, either putting high pressure water into the valve’s control chamber (causing the valve to close) or taking water out of the valve’s control chamber (causing the valve to open). The solenoid is a low-powered device that requires only a short pulse of electricity to flip from one state to the other. The valves chosen were a ¾” Cla-Val Model 139-10A, a programmable timer control valve, which is an on/off control valve that can be programmed to operate on a time schedule.

Alberton says, “It is easy to check-in on the valve and make changes with the interface cable that connects the anti-stagnation valve through a USB port to a computer.” Free software downloaded from the Cla-Val website, is used to communicate to the valve. Once connected a person can check the valve’s position status (open or closed), test the valve by forcing the valve open or closed, determine the valve’s battery level, automatically update the unit’s date/time by synching to the computer, and of course set when the valve opens/closes. “The valve can open up to twice a day, but we normally set it to open once. Like a sprinkler timer, the unit can be programmed to open every day or every other day or specific days of the week,” said Alberton.

Determining the optimal run time of the stagnation valve depends on a few parameters that can vary from one location to another. “Our engineering firm created a spreadsheet to determine how long the anti-stagnation valves need to open for. By entering in the diameter of the pipe that the normally-closed boundary valve is connected to, and the distance to the nearest piping intersection, upstream or downstream of the isolation valve (whichever is longer), the program calculates the total volume of potentially stagnant water on one side of the boundary valve. Then we input the upper zone and lower zone pressures which are normally constant. And lastly, we can ‘play’ with the size of the anti-stagnation valve – trying different sizes to see what is the most suitable for the application,” said Alberton.

The program takes the valve’s size, converts that to its Cv and can then calculate the flow through the valve using the equation Q (flow) = Cv * square root of the Dp across the valve. The volume divided by the flow rate gives the City the time required to flow the entire volume of stagnant water through the valve.

To meet the need for high demand and reliability without fail, the latching solenoid is a high-quality unit, and the entire valve, including the solenoid, is rated to 232 psi. It can range in size from ½” to 4”, but most common is the ¾”. The unit runs off a long life 9-volt lithium battery and the whole assembly is IP-68 submersible which is important to have in a valve chamber where flooding can happen. The battery is rated for three years of service, but the City prefers to err on the side of caution and replace the batteries every year during regular maintenance checks to ensure the valves are working properly and continue to do so. “In the worst case, if the battery runs out of power, the valve will cease to function, but is designed to fail in the closed position. The unit will retain its program so that, when a fresh battery is installed, the program does not have to be re-entered. When connected to a computer the unit will synch to its date,” said Alberton.

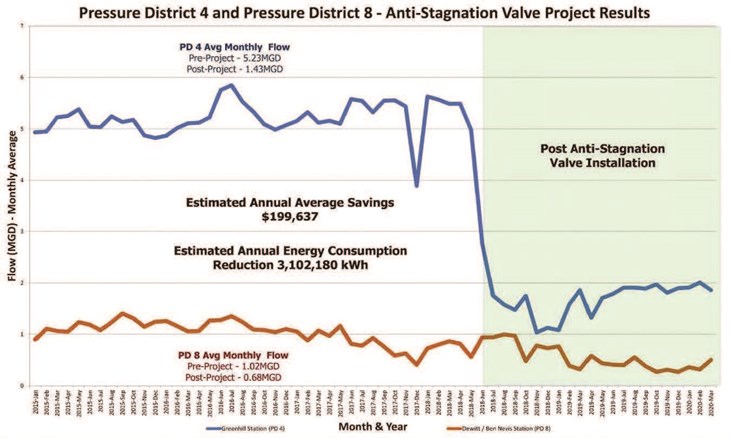

The pilot project focused on 37 water distribution level valves and open bypass lines that separate the two pressure districts. The previous one-year historic pumping station electrical demand (kW) and energy consumption (kWh) were used as a baseline for the pilot project.

The post-retrofit period is being continuously monitored using the City of Hamilton – Office of Energy Initiatives to gather electrical demand (kW) and energy consumption (kWh) data to verify actual project energy savings and electrical demand reduction.

Based on the product calculations, it was estimated that each valve would save 44,000 kWh of energy, or 1,628,000 kWh per year in total for 37 valves. This was based on a 185-kW reduction in electrical demand and a 24/7 process operation. However, the valve timers were set for 15 minutes which is shorter than the original time used to estimate savings, so the actual energy savings were even greater.

Energy Savings

Graph 1 shows the flow before and after the anti-stagnation valve installation. The actual results of the pilot study were a monthly savings of 258,515 kWh which equates to a reduction 3,102,180 kWh per year of energy use. This translates into an annual cost savings of CDN $199,637 for the pilot project. With a total installed project cost of under CDN $90,000, the simple payback is under five months for this technology.

Water Savings

Using anti-stagnation valves has enabled the City to eliminate stagnant water concerns and reduce water consumption. The valves are programmed to open at staggered times in order to minimize impact to the system. By flowing during the day-time, when there is normal demand, these valves can reduce and even eliminate over-pressurization in the lower system. As they flow for shorter periods of time there is less wear and tear to the chamber piping, significantly reducing breaks do the ¾” line elbows and fittings that occur due to high velocity flow and cavitation issues. Since the pilot project watermain breaks have decreased by 15% resulting in a reduction of non-revenue water loss.

Equipment Savings

By reducing flow, the City will also reduce equipment costs associated with delivering that water in three key areas.

1. Annual Maintenance

As pump usage is reduced by 50%, maintenance costs should decrease by 50% (based on running time)

2. Pump Replacement Costs

With 50% reduction in operation, each pump’s life expectancy will double. Therefore, replacement cost will drop by half on a yearly basis.

3. New Station Costs

- If the original plan were to use 4 pumps but now only 2 are required, new station costs will decrease significantly.

- With a reduced number of pumps, station size decreases as does its complexity since the station will require less valves and associated piping.

The pilot project (phase 1) has clearly demonstrated that incredibly significant energy savings and water reduction for the City of Hamilton is achievable using the anti-stagnation valve technology in its pressure district zones. “We have a culture of continuous improvement at Hamilton Water, so with such a positive ROI and reduction on energy consumption, we are now in the process of rolling out two more phases. Phase 2 will involve the installation of an additional 37 valves, providing an energy savings estimated at 445,000 kWh per year or a cost savings of CDN $62,000. And phase 3 will see the installation of a further 36 valves, estimated to reduce energy consumption by 400,000 kWh per year or estimated cost saving of CDN $55,000,” concluded Alberton.

The City of Hamilton is well on its way to improving operational practices that reduce carbon emissions with the end game of 60% reduction in emissions by 2050. “Every effort counts when it comes to saving the planet for our future generations. I encourage all municipalities to step up to the challenge – the technology is there, it is up to us to implement it,” concluded Alberton.

About the Authors

Peter Sucharda, P.Eng., is president of Devine & Associates, which works with end users, consultants, and contractors to design, produce, implement, and support fl ow solutions for water, wastewater, stormwater, slurry, and other fluid applications.

Mark Gimson is director of marketing and international sales for Cla-Val Company. Cla-Val is a world-leading designer and manufacturer of automatic control valves. From reducing and relief valves to deluge, air valves and more, Cla-Val manufactures and provides a wide variety of solutions for use in some of the world’s most demanding applications.