By Stephen Cherlet – FarStar Consulting with Manoj Kumar – Inde Dutch Engineering & Aerospace Services Ltd.

Posted by Sarah Bradley.

Good Old Days

Back when I studied engineering, everything was still pencils, t-squares, set squares, ovals, and perhaps a flex-curve. In my first job at the aircraft factory, the print room worked with aperture cards and printed massive amounts of paper. Hard copy was the only way to check even a few dimensions. In those days, there was no such thing as looking at information on a screen except for standard items like for fasteners, washers, and rivets that could be viewed on microfiche or microfilm.

Back in those days, 2D was expensive and 3D design tools cost small fortunes. I remember at various employers, we had two designs teams – one with drafting tables and with a 3D CAD (Computer Aided Design/Drafting). As this was emerging technology at the time, the hardware and software was so expensive firms could afford to convert all at once. Surprisingly, or perhaps not, a lot of ‘paper’ drawings are still in use. Though I seldom encounter companies generating new paper-based drawings, the legacy data still remains intact as hard copy. Typically, the old prints and vellum has been scanned making the drawing available in an electronics format, usually Adobe PDF. These are typically old items that are not in production but needed for spare parts. They can be part of really old designs. When the need for change arises, these companies usually take the opportunity to re-draw the part using a CAD tool. This slowly brings everything into a digital world. Depending on the item, firms may only re-create the part in 2D. This is especially true if the part is not used in a higher assembly, eliminating the need for 3D to be able to check for fit.

2D Was the Rage

Eventually, the cost of both hardware and software came out of the stratosphere. Instead of paper and electronic design/drafting teams, we ended up with a combination of 2D and 3D teams. At least paper was slowly being phased out. With 2D, there was some improvement in overall drafting time. Derivative parts were easier to create. Electronic information sharing got simpler both internally and externally. Then, and often still today, companies print a hard copy for signature. This prolongs the concept of paper as the master data source.

Moving to 3D

Although some of the 3D design tools still seem to be as expensive as ever, at least there are some lower cost alternatives combined with much lower hardware costs. For the same number of dollars (cost) of a mid-80’s word processor, you can get a pretty good workstation today. Gone are the days of high-end (read expensive) RISC (Reduced Instruction Set Computer) work-stations from the likes of Sun Microsystems and others. Now regular personal computer hardware, properly specified, can get the job done. Cost is no longer a real obstacle.

But What About the Benefits?

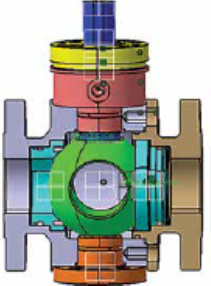

Beyond the original benefit of being able to model full assemblies to check for interference and fit, there is a cornucopia of tools able to import a 3D model for a variety of analyses.

Although we have been referring to design applications, we cannot forget about industrial engineering. Computer Aided Manufacturing (CAM) software facilitates the creation of numerical control programs for the production of machined parts, laser and water jet cutting, EDM (Electrical Discharge Machining) and robotic welding among other processes. In addition to generating tool paths, the software can often check for interference between part and machine. If the fixtures have also been designed in 3D then the process team can often also check for machine, or tool, interference with the fixture as well. Not only is there in decrease in the cycle time to prepare for production there is a decrease in tool-part-fixture collisions potentially causing serious damage, injury or delay.

From the design side, having a 3D model lends itself to design validation through FEA (Finite Element Analysis). FEA can be used to predict how a product will reacts to real-world forces, vibration, heat, fluid flow, and other physical effects. Finite element analysis guides designers as to whether a product will break, and at what point, or work the way it was designed. Popular packages include ANSYS, SolidWorks Simulation and AutoDesk CFD (Computational Fluid Dynamics), and others.

Important to the valve industry is the ability to simulate metal flow and cooling for the casting process. High end software tools like MAGMASoft, Pro-CAST, and Flow-3D CAST can all contribute to improving the designs of castings to improve both product quality and yield. These tools are needed to detect part shrinkage and directional solidification. A result of such analysis could be the addition of a riser(s) at critical locations in the mold. It is much better to find problems, and resolve as many as possible in advance, instead on the foundry floor.

The availability of the digital object is a key to supporting supplier collaboration for any process. Some foundries, in fact, will offer to run the casting simulation for you if the 3D model is provided. Machine shops, and any supplier with robotic processes (like welding or painting), will also appreciate being supplied with a model.

Now, with the advent of 3D printing, or additive manufacture, companies can send the digital model to a supplier and receive a physical part back. There is also the option to invest in the printing equipment and bring the process in-house. New printing process are permitting the use of advanced materials. Direct metal laser sintering (DMLS) is an industrial metal 3D printing process that “prints” fully functional metal parts in a matter of days from start to finish. A range of metals produce final parts that can be used for end-use applications. Those materials now include cobalt chrome, titanium, inconel, tantalum, tungsten, stainless steels, and custom alloys.

Where to Next?

We talked about simulation in the creation of parts and processes. The same simulations can be produced as instructional videos. They can guide machine operators with respect to fixture installation on a machine, part placement in the fixture, and even provide a preview the tool path. In the assembly department, videos can be used as general training aids or for specific tasks. Naturally, still images from any of the simulations can be similarly used. If you have customer serviceable products, the in-house assembly videos can be turned into instruction aids for customers or authorized repair centers. Ultimately, all of this can be done in a completely immersive Virtual Reality (VR) environment.

How Do I Get There From Here?

For those who still have hard copy documents, there are a variety of services to digitize your information. Scanning services to produce 2D vector drawings have been around for a long time, and the quality of the output has improved. Some services will offer human expertise to review and clean up the newly vectorized results. In fact, with the gig economy, there are companies, and freelancers, who will perform the conversion process for a flat fee.

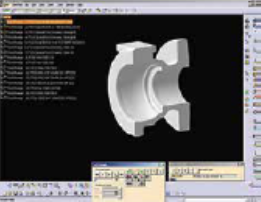

The real issue is getting from paper, or 2D CAD, to 3D. This still takes a human being, so, if you are not doing this in-house, you will need to contract with a services company. Choosing a business partner with the correct experience is paramount to a successful conversion project. A critical success factor is to have a an agreement on the key parameters of the model – dimensioning standards, defined use of layers, tolerances on precision, etc. All of this is needed to ensure the quality of the result and to avoid over specifying needs which can result in with massive file sizes

An option could be to use 3D scanners and create the basic model from an actual part. Scanners, like most electronic hardware, have come down in price but are still expensive. Depending on the part some holding fixtures could be needed but still a fast way to get started on your digitization project. The downside is that the model will reflect the as-is dimension of the actual part not nominal dimensions with tolerances. That will have to be applied afterwards.

Although the foregoing has been a discussion about component parts, some firms are actually scanning plants and piping to generate models of the “as-built” configuration. This provides the foundation for documenting the state of the building and can be integrated with enterprise asset management and computerized maintenance management software. The glue that binds all this digital information together is the PLM (Product Lifecycle Management) system. PLM provides the relationship of all the data to each other, manages changes and allows you to execute at speed.

Conclusion

Its becoming a fully digital world and the time has come to fully embrace it. From concept to production, all the processes in between are accomplished more easily digitally. Digital supports both customer and supplier collaboration. Mock-ups and models can be produced for visualization to aid in the design process. At the other end of the supply chain, suppliers can get ready for production, and produce faster, with a full 3D model. Take full advantage!

About the Authors

Stephen Cherlet is a senior management professional with 35+ year of experience. A graduate of Aerospace Engineering Technology at Ryerson (Toronto, Canada), he has worked in aerospace and defence for Bombardier Aerospace and Honeywell. His last role in industry was COO at Velan Inc, a well-known valve manufacturer. Currently, Stephen is the owner/founder of FarStar S.A.C. Consulting. He is also the Chair of the National Board of Directors at Supply Chain Canada.

Manoj Kumar is a senior management professional with 22+ years of experience. He is working as a Business Head at Inde Dutch Engineering & Aerospace Services Limited (IDEAS), an AS9100 D certified organization. IDEAS team has 20+ years of experience in Engineering Services including Digitization (2D paper / electronic drawings to 3D models and vice versa), Data conversion from one engineering platform to other, reverse engineering, NC programming, Quality engineering and Manufacturing Analytics for adjacent industry verticals.