Through accurate design and advanced machining, FBV is one of the leading valve manufacturers in the industry. With customized solutions for every application, FBV prioritizes customer satisfaction, and quality, above all else. By adapting to the market needs, and facing challenges in today’s world head on, the company continues to innovate and improve its product offerings and solutions.

Valve World Americas recently had the pleasure of speaking with Lee Fang, Facility Director at FBV Incorporated, and Leo Fang, Managing Director, concerning the future of the valve industry amidst changes to global markets, green hydrogen, renewables, and fugitive emissions.

By Angelica Pajkovic

FBV at a Glance

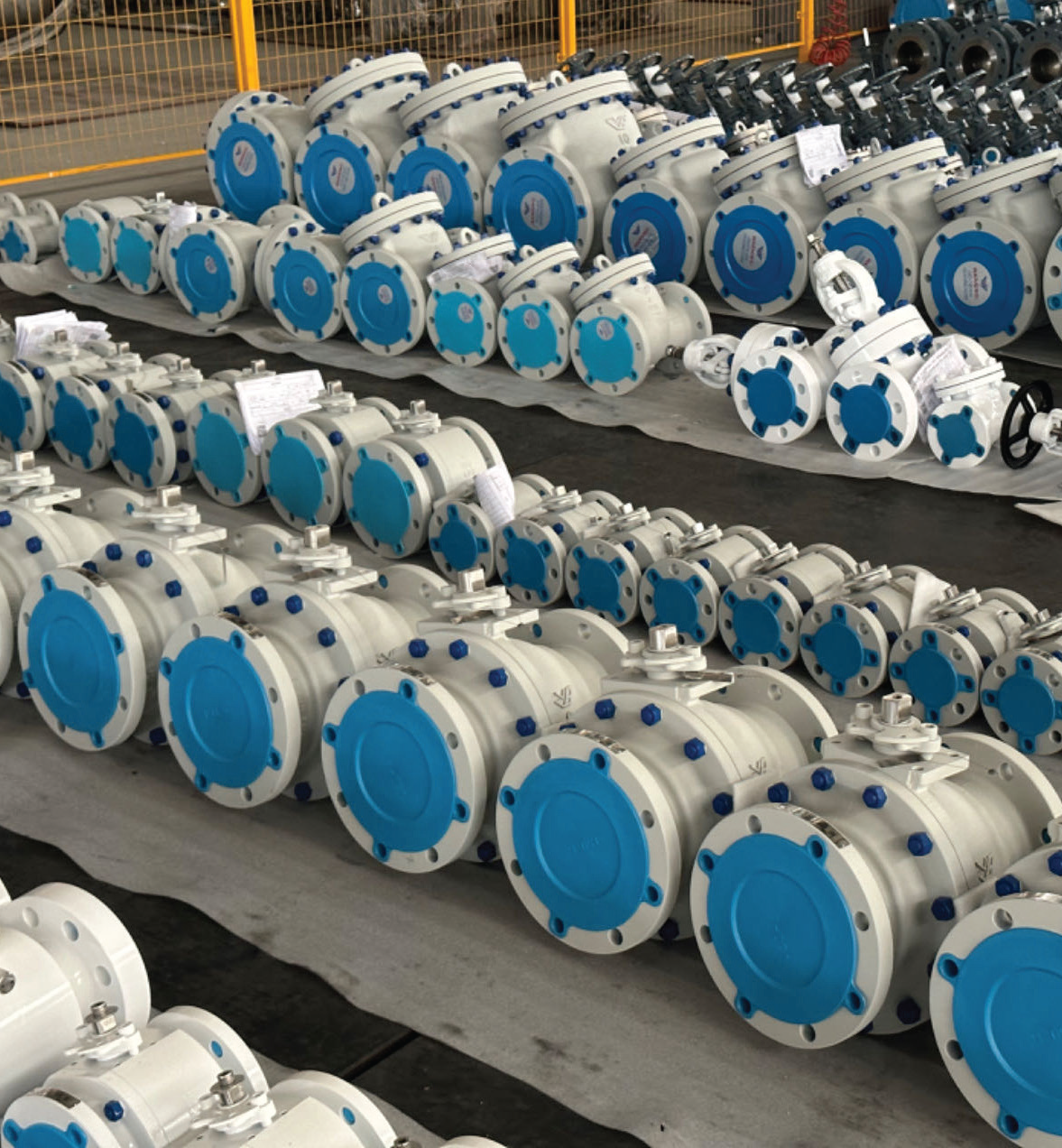

FBV Inc. is an ISO 9001 certified company, that was first established in New York in 2007. Over the last 17 years, the valve manufacturer has expanded internationally and grown its offerings to include several valve products such as: ball valves, gate valves, globe valves, check valves, plug valves, and butterfly valves, in carbon steel, stainless steel, duplex stainless, and alloy materials. Its products conform to the latest industry standards in accordance with ANSI, ASME, and API.

Today, FBV has over 600,000 square feet of manufacturing facilities. Through its conviction to provide only the finest quality products and services to match the need of its customers, FBV has established itself as a serious player in the valve business. Not only has the company expanded its scope in terms of technical expertise, it has also grown its corporate culture. With an extensive network of sales, service, and distribution in North America, South America, Middle East, Southeast Asia, Africa, and beyond, it offers timely delivery for the various needs of its customers.

In addition to general ball, gate, globe, and check valves, FBV develops customized valves such as Cavity Free Top Entry Ball Valves, Multiport Ball Valves, and Twin-Seal DBB ball valves. These products are available in a variety of materials including carbon steel, stainless steel, Hastelloy, Monel, and duplex. Once completed, the products are utilized in the oil & gas, petrochemical, chemical, power, mining, FPSO, and marine industries. Overall, FBV is poised to be one of the greatest influences on the future of the valve industry due to its progressive mindset and vast array of services and locations.

Unique Capabilities

To maintain its position as a leader in the valve industry, FBV dedicates a significant number of resources to its research and development. “Specific problems deserve a specific solution, and sometimes require a specialized valve or design,” explained Lee. “That is why we often engineer products on a project-to-project basis. For ex- ample, it can be very difficult to fabricate applications that require the use of softer materials; one of FBV’s most recent remedies to this challenge is 3D printing.” As 3D printing softer materials are not as common as 3D printing with harder ones, FBV is in the process of writing to the developer for softer materials solutions.

In addition to 3D printing, FBV is also experimenting with technologies in artificial intelligence (AI); it is currently in the process of designing some AI for its testing and manufacturing departments. “Right now, we are interacting with new technology that will completely change this industry. Ensuring that we are at the forefront of these advancements will enable us to adapt to the new innovations, get ahead of the competition, and continue to be successful by providing quality products and services,” said Leo.

While there are different certifications required for 3D valve parts, since they are not as widely used in traditional applications, FBV is in the process of incorporating both 3D printing and AI into its engineering department.

Recognizing the importance of traceability and quick access to information, FBV has also taken action to develop comprehensive management system software to ensure the accuracy of data and efficiency, to integrate customer requirements into the final products. The software covers CRM, ERP, MES, QMS, and SRM functions.

Global Supply Chains

Considering the recent social and political difficulties, the valve industry has had to innovate and improvise in several ways. The COVID-19 pandemic, in particular, forced world travel and shipping to a halt, leaving many companies to reconsider how to approach the changing markets. One issue that the pandemic, and the war in Ukraine, have really brought to light is the need for a more diverse international supply chain and a larger amount of domestic natural resources.

While many countries have tried to protect their domestic income, they have also lost out when it comes to productivity since they depend on other countries for raw materials.

“Over the last five years, the situation has changed, and a lot of countries realize that they do not want to rely on other countries to produce and ship their goods. I think that is why we began to standardize our products and other components. We need products that are more interchangeable and adaptable,” stated Leo. FBV manufactures casting materials all over the world and intends to keep coordinating with many different countries in a joint venture, to ensure its supply chains are not impacted.

Green Hydrogen & Renewables

According to Leo, “FBV has greater capability for research and development than ever before. The company has been making investments in several promising markets, and one of the innovations we are most excited about is hydrogen service-specific products.” Hydrogen is widely recognized as more environmentally friendly than many other natural gasses. As it has smaller particles than other gasses like helium, however, the transfer and combustion processes are more complicated. “Hydrogen needs to be handled differently, especially during production. We are therefore investing in these areas as we know they will be significant in the future,” added Lee.

FBV has also been working on more renewable energy projects. In the past, renewables were not a high priority for the valve industry, but in recent years, customers have been asking about it. Climate change is a global concern, and every single industry is working in some way towards greener solutions to traditional processes.

FBV has a lab that is dedicated to testing new greener technologies, such as manufacturing valves at higher temperatures. The company offers a full range of products that have been tested to ISO 15848-1 and API 624 standards, to meet the market requirements for low emissions. They are not alone in this goal; many countries across the world are working on reducing their fugitive emissions out of concern for the environment.

With green technology and standardization at the forefront of the valve industry, FBV is well positioned to continue to be a key player. Its commitment to its customers, to the environment, and to scientific development, has made it a prominent name in the industry.

“FBV has greater capability for research and development than ever before. The company has been making investments in several promising markets, and one of the innovations we are most excited about is hydrogen service-specific products.” Leo Fang

Final Thoughts

“In oil & gas, I believe that many people have already developed their habits and their systems, and sometimes those do not translate to efficient or progressive solutions,” explained Lee. The solution needed involves new designs and engineering techniques. Renewable energy is ‘like karma’ according to Lee; hydrogen and other green technologies are the future. Oil & gas is seeing a decommissioning of carbon plants, and these plants will eventually be switched over to more modern plants, like hydrogen.

“We needed to look at customer demand and develop solutions that anticipate the end user’s needs for not only today, but tomorrow as well,” he concluded.