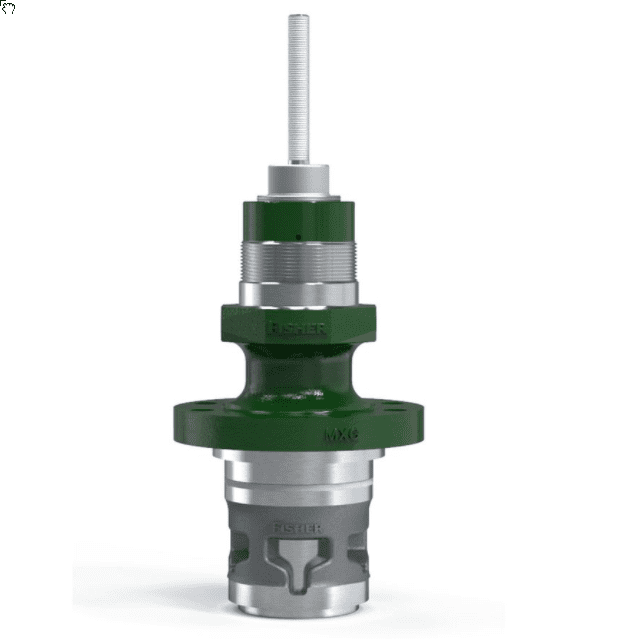

Emerson has announced the release of its easy-e™ Trim Cartridge, a complete trim repair solution for Fisher™ easy-e globe valves. This factory-assembled repair cartridge combines all valve replacement parts, plus the bonnet, into a simple and ready-to-install repair solution, streamlining the repair experience while creating time and money savings throughout the maintenance process.

Before the introduction of this solution, any suspected globe valve issues, such as leaking or sticking, typically required disassembly of the valve to identify the required replacement part(s). Once identified, the parts had to be ordered, and then installed after receipt. In the best case, these activities could be performed in the field by an experienced technician, albeit with some difficulty due to the required precision of installation tasks and the multiplicity of parts. In the worst case, a valve would need to be removed from service, resulting in significant added repair cost and labor, and additional downtime.

The Trim Cartridge only addresses all these issues related to wear parts, and it also helps mitigate fugitive emissions with standardized ENVIRO-SEAL™ packing. For older valves without this type of packing in place, the Trim Cartridge provides a quick, simple, and cost-effective upgrade to reduce emissions.

With this new solution, inline valve repair is typically feasible once process media and pressure have been removed from the valve, and it can be performed by any technician, without the need for extensive training or expensive equipment. Safety is improved by reducing technician time in the field because a typical repair process requiring the assembly of up to 20 parts has been simplified into a single, ready-to-install control valve repair solution.