By Michael Boylan

Each valve applied in a space application is composed of a series of seals with varying functions, sizes, and geometries. These seals operate in one of the most severe, mission-critical environments in the universe characterized by extreme variations in media, pressure, and temperature. Cryogenic temperatures are at the forefront of space applications. Sourcing seals and sealing materials that are proven and appropriate for cryogenic temperatures present some unique challenges. We will discuss factors that make cryogenic sealing difficult and some field-proven solutions.

Sealing Challenges

To understand how to select seals that meet the requirements of cryogenic space applications, it is important to first understand the key factors that make cryogenic sealing a challenge— media variations, temperature range, and people safety.

Regarding media, a wide range of fluids are used in space and LOX (liquid oxygen) is one of the most prominent. An equally wide range of gases are used, including nitrogen, hydrogen, and helium. Added to the mix are operating temperatures rising as high as 500F and plunging as low as -420F. Polymers and fluoropolymers used in this environment are challenged by numerous variables that compromise a seal’s material composition. Successful sealing under these circumstances requires a high level of supplier and customer collaboration centered squarely on selecting the best materials, optimum design, understanding the customer’s hardware, and manufacturing methodologies based on the supplier’s experience. Most important, the way these variables are managed have a direct impact on the safety of staff working on the ground and onboard spacecraft and launch vehicles. There is an extremely low tolerance for leakage in space applications because leaks can expose everyone involved to risks associated with flammable and combustible liquids and materials.

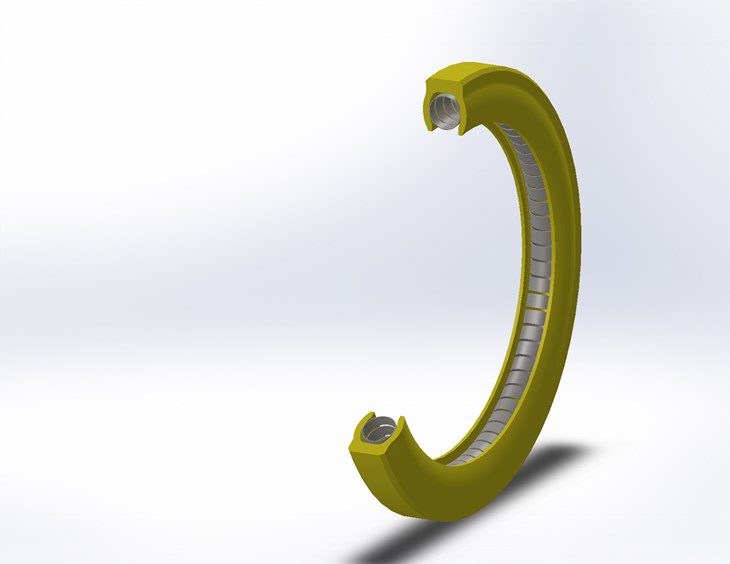

Cryogenic valves for space exploration are mainly used in propulsion systems and actuators that deliver and create propulsion. Primary valves are larger than secondary valves that support the flow of fuel and gas into the system. Both are supported by three types of seals that cover the full application of valves: face seals, which are static; radial seals and ball valve seals, which may be static or dynamic. As a rule, much thought must be given to what is being sealed. Sealing materials must be compatible with the type of media being sealed and the design. Material selection is very important because an inappropriate choice can lead to a multitude of other challenges.

It is also important to keep permeation of material in mind. For example, it is extremely difficult to seal gases like helium and hydrogen. Dense materials are more suitable to prevent leakage. Butterfly valves also come into play in cryogenic applications involving LOX. Since a high spring load is required, the butterfly valve is not very typical for space applications and often better suited for industrial cryogenic applications. It is worth noting that there are several valve sealing lessons to be learned from space propulsion and cryogenic delivery applications. These lend themselves to other industries, such as oil and gas and specialized industrial because the technology is proven.

One of the greatest pathways to finding solutions to the challenges presented is in the design and manufacturing process.

Solutions-based Design and Manufacturing

Sealing projects for space applications generally begin with the OEM or supplier that manufactures the valves or builds the boosters interacting with a seal supplier’s technical sales staff. After reviewing the application with the customer to understand all the parameters, engineering design work begins. A prototype is developed, and the seals are tested (and retested, even after successful tests are completed) before they go to production. For space applications, rapid design is vital in delivering an article that the customer can test.

The next big step in the process is choosing the right material which is often a special grade appropriate for the range of temperatures and fluids. Selecting the right seal design and manufacturing method is next followed by the critically-important step of ensuring that the seals are cleaned to a degree that meets the certified cleaning specification before customer delivery. All of this must be done quickly.

Since space customers assemble in a clean room environment, having parts arrive in a cleaned package that can be quickly put into production saves time and money. After parts are produced, they undergo stringent quality and traceability documentation. Seal suppliers who qualify for the work maintain the highest quality management certifications required, such as AS9100D with ISO 9001: 2015.

A customer recently benefited from this process when faced with a perplexing surface finish issue. The customer was experiencing leakage on a cast iron valve for rocket engines produced with a 3D printer. After the supplier and customer thoroughly investigated the problem, the team determined that the seal was not the source of the leak. The material used in 3D printing was porous and allowed the fluid to absorb and leak through the metal system. PCTI employed a proprietary manufacturing method for surface finishes to help the customer achieve the desired result. Experience in surface finish, as it relates to hardware, is yet another solutions-based process that is important to consider.

Conclusion

As a manufacturer of seals to support valves used in space applications, we interact with OEMs regularly and have noted an interesting trend taking shape. There is a push for repeat service on certain seals that were traditionally designated for single-use. This shift will require suppliers to adhere to higher material and design standards along with ever-improving manufacturing processes.

About the Author

Michael Boylan is general manager of Apple Valley, California-based Polymer Concepts Technologies, Inc. (PCTI). In this role, he serves as the company’s business leader, directing sales and strategic growth activities. With more than 20 years of sealing industry experience, his background includes roles in technical sales, operations, and business management.