By Crane I&S

As was recently announced, Instrumentation & Sampling (I&S) businesses including the brands of HOKE®, GYROLOK®, GO REGULATOR®, DOPAK® and TEXAS SAMPLING® have been acquired by Crane Co., a diversified manufacturer of highly engineered industrial products. With more than 165 years of industry experience and 12,000 employees across 25 countries, Crane Co. has a vast footprint.

Now, known as Crane I&S, this entity operates within Crane ChemPharma & Energy (CP&E), Crane Co.’s largest business in its Fluid Handling segment. Its trusted brands further complement Crane’s existing portfolio, aligning directly with the objective of providing solutions for demanding chemical, refining, and power applications.

Exploring Instrumentation and Sampling as a Solution

Instrumentation and sampling are two critical aspects of the Fluid Handling industry that can significantly affect the outcome of the process and contribute to the health and safety of operators and the environment.

Essentially Crane I&S’ instrumentation products connect the process to the instrument to measure and control variables, including pressure, flow, level and analyzers for liquids, gasses and vacuum.

Its sampling products and systems, on the other hand, facilitate the safe collection of media from the process (a gas, vapor or liquid) that is then transported to a lab for testing and analysis. Without the use of our products and systems, the extraction of toxic samples can be an incredibly dangerous process, as it increases the risk of uncontrolled release, presenting significant safety hazards to the operator and the environment.

With the most comprehensive portfolio of valves, pipes and fittings, the addition of some of the industry’s most respected instrumentation and sampling brands allows Crane to provide even more comprehensive solutions.

HERITAGE OF INNOVATION

INSTRUMENTATION VALVES & FITTINGS

HOKE® valves and fittings are recognized as the best in class for reliability and global distribution. In the early 1960’s, HOKE introduced the GYROLOK® tube fitting with a design that offers innovative advantages and benefits that are unmatched in the industry.

SAMPLING SYSTEMS

In 1926 Dovianus began as an instrumentation and equipment manufacturer. In the late 1970s, DOPAK® sampling systems were internationally acclaimed for its performance and quality in closed loop and closed vent sampling systems.

TEXAS SAMPLING INC. is focused on the application, design, support and supply of custom engineered grab sample systems in industrial environments.

REGULATORS, DIAPHRAGM VALVES & FILTERS

GO REGULATOR® is a leading global designer and manufacturer of standardized and specialty pressure regulators, diaphragm valves, and filters to the analytical, instrumentation, petrochemical, oil & gas, and specialty gas industries.

Five Brands… 10 Decades of I&S Leadership

Over the course of 95 years, this business was built on the trust of its flagship brands HOKE®, GYROLOK®, GO REGULATOR®, DOPAK® and TEXAS SAMPLING® each bringing with them a distinct level of quality and performance in the instrumentation and sampling space that continues to this day.

HOKE® & GYROLOK®

In 1925, the foundation for a leading global fluid control products company was laid when HOKE® began manufacturing small gas flow control valves for jewelers’ torches. In the early 1960s, HOKE® expanded its portfolio when it introduced a line of tube and pipe fittings branded as GYROLOK® featuring a patented design and offering innovative advantages that remain relevant today.

Celebrating decades of proven success in a wide range of industries, including chemical, pharmaceutical, oil and gas, power and refining, the HOKE® brand continues to specialize in small bore instrumentation products up to 2” across a broad range of corrosion resistant alloy offerings. Its portfolio has expanded since it was established to now include:

• GYROLOK® Tube Fittings, the industry’s most technically advanced line of twin ferrule tube fittings for connecting pressure system in tube from 1/16” – inch to 2” inch OD & (4mm to 38mm) from vacuum to pressures of 15,000 psi (1020 BARG) in a range of materials including 316, Brass, Titanium, Hastelloy C, Inconel, 6MO and Duplex alloys.

• A complete line of Sampling Cylinders, available in different alloys with capacities from 75cc to 3785 cc (1 gallon).

• A wide range of Instrument Valves spanning ball, plug, needle, check, pack-less (diaphragm and bellows sealed), pneumatic actuated, relief, bleed, toggle, plug, metering, excess flow, manifolds, gauge, hand and DBB in sizes from 1/16” to 1”.

• Compact Space Saver® electric and pneumatic Actuators available in a variety of designs for the complete line of HOKE® valves.

• HOKEBlock® and Monoflange which are designed specifically for (1) primary and/or secondary process isolation, (2) vent and calibration access, or (3) sampling applications and flanged process piping, offering a more compact, rigid, lighter, safer and more cost effective solution than the conventional piping methods which are used for primary and/or secondary isolation, vent and calibration.

• GYROLOK® Flanges that provide a simple interface between pipe flanges and instrument fittings, eliminating the need for pipe threading or welding and minimizing the size and weight.

• A complete line of Precision Pipe Fittings, available featuring NPT, SAE or welded ends.

NEW GYROLOK™ XP FITTINGS

Crane I&S recently introduced the GYROLOK™ XP, an advanced fitting engineered to deliver a higher integrity seal in mission-critical situations. Considered a “game changer” in severe service designs, the new XP directly addresses the technical weakness of fittings that feature a wedge-type front ferrule design.

Wedge type front ferrule designs, for example, can be over-tightened which can lead to lower pressure and safety issues. These fittings’ applications are sometimes subject to rapid temperature changes which can lead to (1) leaks, (2) fatigue damage where exposed threads contact corrosive materials and (3) vibration which can result in fatigue failures of screwed pipe joints. The GYROLOK™ XP, however, features a front ferrule with unique mechanical stop that prevents overtightening and a sizing angle that prevents tube sticking. These changes offer several benefits, including:

• ~50% higher pressure rating compared to competitors, enabling more options for specialized alloys and media than competitive options.

• 70% more material in high stress areas, decreasing the necessary maintenance cycle and significantly reducing maintenance costs.

The GYROLOK™ XP has the broadest alloy offering in the industry, with more than 10 available, making it suitable for a wide range of severe service applications.

GO REGULATOR®

Around the time GYROLOK® was introduced, GO REGULATOR® was founded (1962), eventually becoming a globally recognized designer and manufacturer of standardized and specialty diaphragm valves and filters to the analytical, instrumentation, petrochemical, oil & gas and specialty gas industries. Furthermore, its line of pressure regulators includes single stage, back pressure, dome-loaded, high purity, liquid and gas pressure regulators, as well as filters for process analyzers.

The diversity of the products in this portfolio and their ability to control pressure while accommodating low to moderate flow rates of many gases and liquids, enables them to be used in a vast range of applications for use in gas, liquid or hydraulic systems requiring accurate pressure control, integrated and accurate spill control, low operating torques, and reliable functioning/sealing over an extended service period in applications involving pressures up to 690 barg/10,000psig.

DOPAK®

One year after HOKE® was established, DOPAK® Sampling Systems was founded (1926), introducing a range of highly functional samplers for the chemical and petrochemical industries.

Traditionally, taking samples of toxic, dangerous and volatile substances presented a range of risks to the operator, the environment, and even the sample itself if it wasn’t properly contained. Spills were a serious risk factor capable of putting many in danger, yet the sampling process was necessary in ensuring product verification.

Understanding the complexities of this process, the need for tests and analyses, and the inherent risks involved with taking samples, DOPAK® introduced a new approach to sampling that has become a best-practice concept today. Featuring a patented closed-vent design and simple method of operation, DOPAK® samplers shield the operator from contact, prevent local spillage and the escape of volatile substances, all while protecting the sample from contamination.

DOPAK® offers a variety of standard sampling system models (either closed-vent or open) and sizes appropriate for different materials and the conditions of the process involved. Depending on the sampling system used, one of two sample containers are available: (1) bottles sealed with cap and septum and (2) cylinders. Today, its closed-vent portfolio of sampling systems is the most comprehensive in the industry.

Additionally, DOPAK® offers a range of partly open samplers for low hazardous liquids and those at atmospheric pressure.

TEXAS SAMPLING®

In 1989, Texas Sampling was founded in Houston and was 100% focused on the application, design, support and supply of custom engineered grab sample systems. Operating within the DOPAK® Sampling Systems facility since 2018, the two brands were able to pioneer and shape the grab sample market.

Under the TEXAS SAMPLING® brand, Crane I&S offers several patented systems that can take samples of LPG liquids or gases. LPG sample systems enable operators to obtain samples of liquids with high vaporization pressures via a sample cylinder that can be easily transported. These cylinder saddles help ensure proper alignment and prevent leakage when connecting the cylinder. The design also bolsters operator safety by allowing the operator to maintain the proper outage. Any excess sample left in the system is also vented so that the pressure in the quick connects is reduced.

CT76 MODULAR SAMPLING SYSTEMS

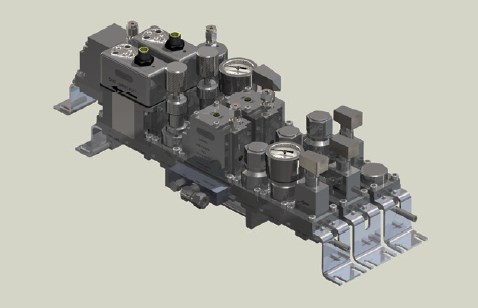

Crane I&S is pleased to present its recently rebranded CT76, a digital flow, pressure and temperature transmitter for use with process analyzers to provide monitoring and closed-loop control of chemical processes.

• Compact surface-mounted modules provide fluid pressure, flow rate, and temperature, in a single unit for predictive maintenance and real time reading.

• Metal-to-metal seals to atmosphere for optimal leakage protection.

• No dynamic O-rings in process stream which enables longer product life (up to 10 years vs. 6 m with traditional methods).

• 0.23 Cv flow capacity, suitable for vapor or liquid process applications up to 500 psig and 50 psig actuation pressure.

• Factory calibrated plug-n-play unit permits cost-effective data collection (40% less vs. traditional methods).

Crane I&S Capabilities

Crane I&S is the largest provider of instrumentation and sampling products in the world. From process to the instrument or sampling point, its portfolio is capable of forming a complete flow solution on its own without incorporating any other vendor products. However, its more than 95 years of engineering and application expertise can also simplify and enhance end users’ existing product solutions by developing innovative applications as solutions.

With facilities in Spartanburg, South Carolina; Houston, Texas; and Bergschenhoek, Netherlands, Crane I&S has the scale required to serve the global industry across the refinery/petrochemical, upstream, chemical CNG/LNG and hydrogen fuel cell applications, as well as other industrial. end markets, including nuclear, hydraulics and industrial gasses. As an example of its reach, products in the Crane I&S portfolio are currently installed in the Norwegian offshore Oil & Gas market, Saudi Arabian chemical plants, natural gas plants in West Africa and North America, marine applications in Sweden, and adjacent markets like hydrogen fuel and CNG, among others.