With engineering expertise, sharp business acumen, and top tier certifications for its flow control products, Netherlands-based Combet Valves is broadening its scope and making efforts to grow in the U.S. flow control market.

By Steve Fennell

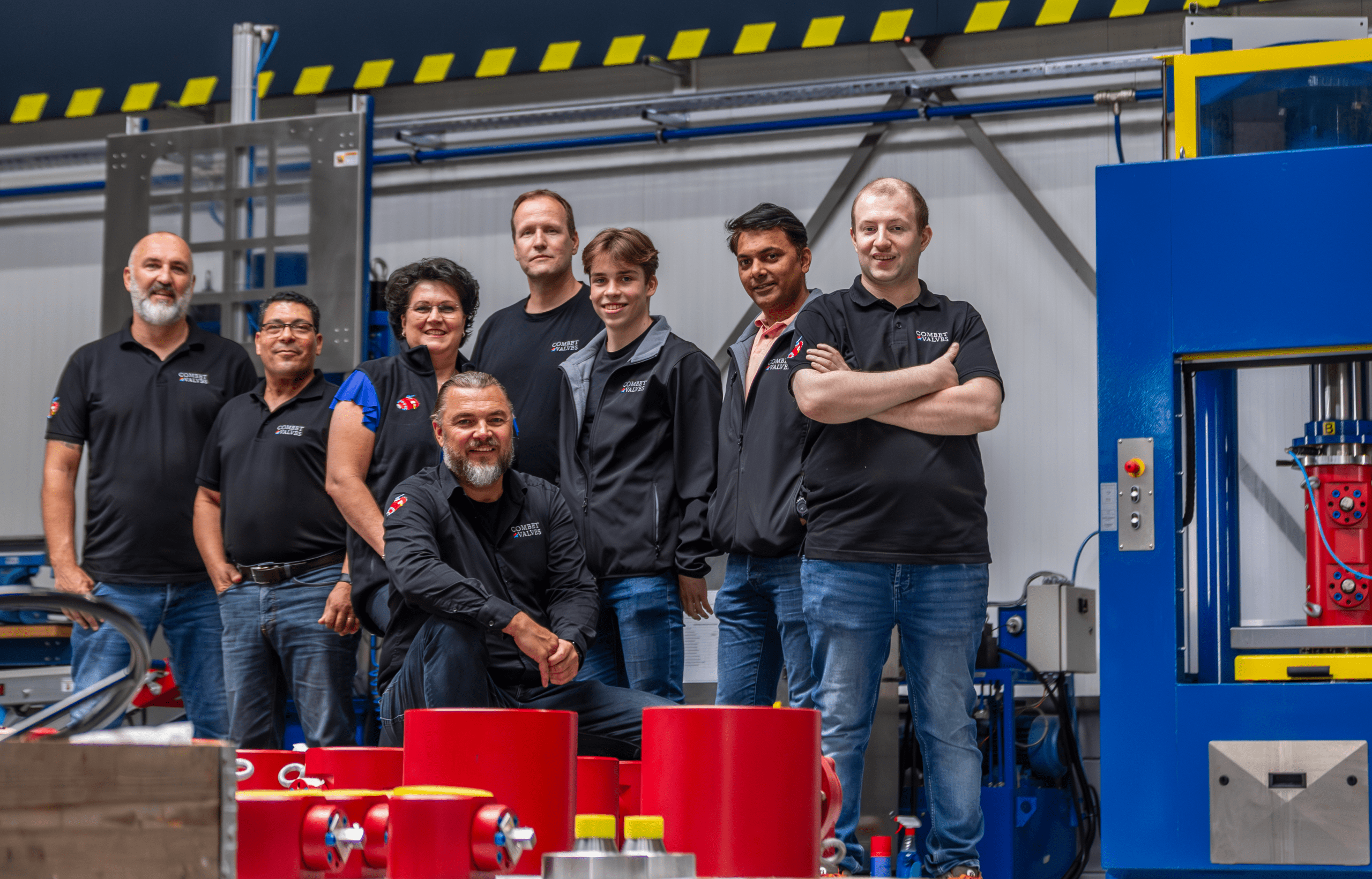

Combet Valves, a manufacturer headquartered in Houten, The Netherlands, has been engineering high-performance, high-pressure, compact valves since they launched operations in 2017. Under the leadership of CEO, Matthieu Smit, and Vice President, Benjie Terrebonne, Combet has established a strong presence throughout Europe and Asia.

In recent years, the company opened a U.S. sales office in Broussard, Louisiana — a strategic location in one of the United States’ leading oil & gas hubs — to further establish its footprint in the U.S. oil & gas market and drive international growth.

Strong Client Portfolio and U.S. Presence

In an interview with Valve World Americas, Smit explained that the types of valves they manufacture were initially developed in the early 1970s, with offshore applications being the focus of the product line. Smit and Terrebonne then began outlining plans to design and manufacture their own compact valves in 2015.

Today, its portfolio of products and clients span both the offshore and onshore oil & gas sectors. They have partnered with a distributor in Louisiana — which covers offshore sites in the Gulf of America — and another in West Texas. As a result, many of its valves are used by top end users, meeting the requirements of companies such as bp, Shell, Woodside, McDermott, Subsea7, Baker Hughes, and Noble Energy, to name just a few.

The High-Quality Tech of Combet Valves

Combet’s high-pressure, high-performing compact valves have a three-piece, modular design, which enables the company to create different configurations for a variety of applications.

Its range of valves come standard with a bevel for weld fittings that are built according to the client’s specifications and industry standards.

Additionally, modular connections like flanges, swivel flanges, and hammer unions, can also be supplied to meet the customer’s needs.

Combet’s arsenal of flow control products consist of unique high pressure floating ball valves, swing-type check valves, compact non-slam check valves, and double block and bleed ball valves. All are engineered for fluid control in demanding environments with limited space, high-pressure and/or deep water where the utmost reliability and safety are paramount.

Design features across its product portfolio are also impressive.

These include large seat cross sections to tolerate unprocessed produced fluid media; hot-rolled solid bar bodies, which provide 26% higher tensile strength and 37% more fatigue strength; and metal-to-metal sealing systems that offer inherent API 6FA firesafe protection.

“Similar valve products are made by U.S. manufacturers,” Smit said. “However, they stock valves with standard trim materials. In the event the customer wants to change some materials, they have to pay additional prices. We do a lot of subsea activity, so our standard design materials are already at a higher level, yet they are available for the similar price as the standard designed by our competitors. That is why we are strong in subsea activities. We offer excellent value for the cost.”

Terrebonne, who manages operations from the company’s U.S. office, added that Combet provides a better-quality option beyond the standard trim typically available. “In the end, we offer an option that is superior to our competitors. It’s in stock and available at a very competitive price,” said Terrebonne.

Stringent Testing and Effective Service

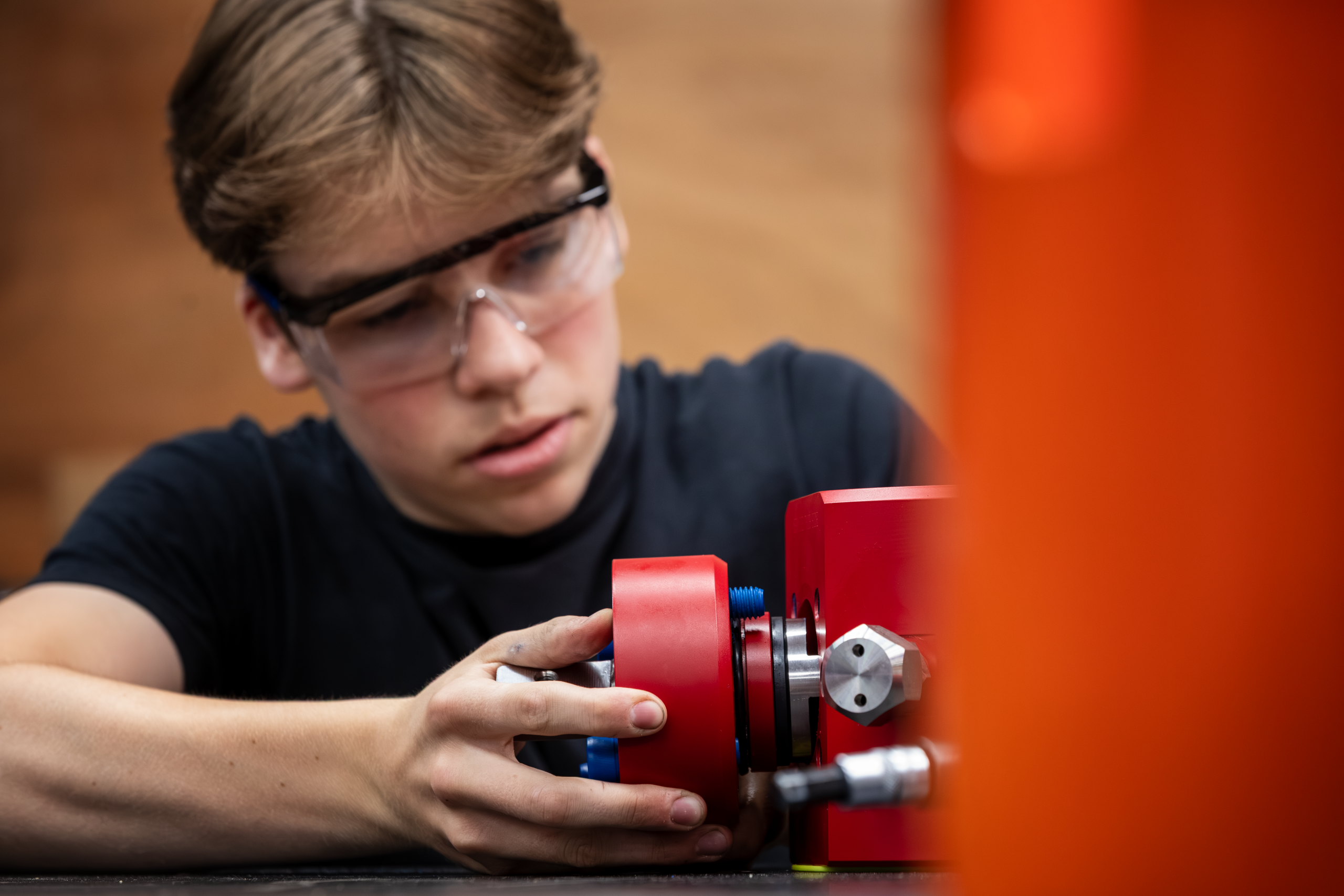

To ensure efficiency, safety, and reliability for its valves, new test benches have been ordered for Combet’s manufacturing facility in Houten. Smit has also been in discussions with one of its US distributors to oversee local testing activities, providing an additional level of service to customers.

Given its test benches are made specifically for Combet compact valves, customers can be further assured of optimal performance and integrity of the valves prior to being utilized offshore and for their intended application.

Meeting Current Industry Standards and Achieving SIL 3 Certification

Combet recently reported they have earned the stringent fire safe testing for API 6FA 5th Edition, which is the most current and active API standard for the testing of ball and check valves for the oil & gas sector.

“This testing standard originated many years ago and has had many revisions,” said Terrebonne. “However, most manufacturers that have had their valves tested are to the older standard and haven’t updated their testing. Our valves are to the current API 6FA Edition 5.”

In mid-October, the company shared that they achieved the Safety Integrity Level (SIL 3) certification for its ball valves. A globally recognized IEC 61508 standard, the certification ensures its product meets stringent safety requirements, represents a high level of risk reduction, and that the valves are fully qualified for use in safety instrumented systems (SIS) across different industries.

It requires a comprehensive, third-party validation process of design, engineering, and testing. Earning SIL 3 has further demonstrated that Combet ball valves meet stringent safety standards and demonstrate a very low probability of failure in safety-critical systems.

“Many of our customers require SIL 3 Certification,” says Terrebonne. “This was a strenuous exercise but it’s also an important certification to achieve, especially for use with actuated valves. We must establish safety integrity for long term use as we sell a lot of actuated valves in our onshore applications in West Texas.”

With its existing ISO 9001:2015 quality management systems certification from DNV, the SIL 3 certificate reinforces the qualification of its ball valves and product reliability. As a result, it significantly enhances Combet’s competitiveness and market access in the flow control industry.

Advantages of Being Active in the U.S. Market

With its efforts to expand in the U.S valve industry, Smit recognizes the challenges presented by the current US tariffs and trade regulations. However, he explains that the company’s current manufacturing model has key advantages.

Since its valves are manufactured in the Netherlands within proximity to a large network of automated machine shops, they are afforded quick access to capacity and flexibility. This also enables Combet to deliver valves at competitive prices with precision and quality.

As compared to managing operations in the U.S. — where distances are greater and machining facilities are more dispersed — valve companies often face increased logistical costs and longer lead times.

“Most of the raw materials for valves that are approved for use in the U.S. generally come from Western Europe,” Smit added. “So, if a company is domiciled in the U.S., they are likely still buying Western European material. This affords us an advantage in that we are only paying for our transportation and shipping once.”

High Stocking Levels and Optimal Efficiency

While Combet is currently making efforts to establish onshore distributors in the U.S. including popular territories such as North Dakota, Colorado, Pennsylvania, and Ohio, valve production at its facility in Houten is running strong. The company’s investments in automated design processes can accelerate the delivery of project documents, which provides significant cost savings and the ability to deliver project documentation quickly. The automated process removes a considerable amount of human error to ensure that clients receive orders on time and on budget.

Combet currently has USD $6,000,000 stock available at their European manufacturing location and over USD $500,000 worth of stock available at any given time in the U.S. and its increasing. This reduces lead times, and its customers are provided with valves essentially when they require them.

“Right now, Combet is the only non- U.S. manufacturer who’s making these valves in the country,” said Smit. “We are strong in Asia and Europe, and as the U.S. market is very large, we are now continuing to be a part of that. Companies who like to sell our products are always welcome to contact us.”