By Kyle Daniels – Clarke Valve

As the United States and many other countries fight to crack down on their environmental footprints to reach Net Zero 2050, many new regulations could be put into place. True climate progress will require all sectors to play a role, and although industries worldwide will be impacted while navigating these new policies, the Oil & Gas industry is one of the major sectors that could be very heavily obstructed by future regulations and rules.

Chemical Contributions to Climate Crisis

Typically called “volatile organic compounds” or VOC’s, common greenhouse gases like methane (CH4) and other compounds have become an increasingly real threat when licensed to operate. With industries worldwide trying to maneuver new guidelines to meet the goal of net zero by 2050, it is more important than ever to utilize our data, experience, and technology modernization to reach climate progress.

An estimated 64% of man-made global warming is caused by CO2, while methane, found to be as much as 26 times as potent, is responsible for 17%. Due to pandemic shutdowns, emissions recorded in the U.S. dropped by about 10% in the past year. To achieve true progress in the years ahead, similar cuts in emissions will need to be made without the same unprecedented circumstances that we saw in the last year.

The concentration of CO2 in the atmosphere has climbed from 280 PPM to 409 PPM since the industrial revolution. With methane being 26 times more powerful than CO2 as a greenhouse gas, 100 PPM of methane is equal to 2600 PPM of CO2 equivalent. The U.S. Environmental Protection Agency (EPA) states that 60% of all fugitive emissions derive from valves, and up to 80% of this leakage is found in the stem-seal interface. The best option available for a low emissions globe valve currently measures leakage at 100 PPM, allowing the valve to continue contributing to the already growing concentration of CO2 in the atmosphere.

Since the passing of the Clean Air Act Amendment (CAAA) in 1990, designed by the EPA to curb major environmental threats like toxic air emissions, many worldwide endeavors have been made to lower industrial fugitive emissions. Despite these efforts, reducing fugitive emissions remains one of the most challenging hurdles that the valve industry faces today.

Lack of Affordable and Accessible Green Technology

During CERAWEEK in March of 2021, philanthropist and investor Bill Gates spoke about energy transition and the cost of switching to cleaner technologies that emit fewer greenhouse gases. Though there are several clean technologies available for implementation, they are not always easily accessible or affordable, and many facilities cannot afford the downtime of this transition on top of the technology costs. This “Green Premium”, or additional cost that is found on clean technology, is one of the major bottlenecks that industries like Oil and Gas encounter on the path to climate change.

An analysis by the International Energy Agency demonstrates that as much as half of the emissions reductions needed to reach net zero by 2050 will likely need to come from technologies that have yet to reach the market. We will not be able to obtain this goal without taking the next steps to improve and implement cost-effective, clean technologies, and make them accessible to the industries that are being pressed to apply them. Many countries including the U.S. have begun creating stronger emissions regulations to push climate progress, but net-zero emissions cannot be achieved without every global industry’s efforts to be a part of the solution.

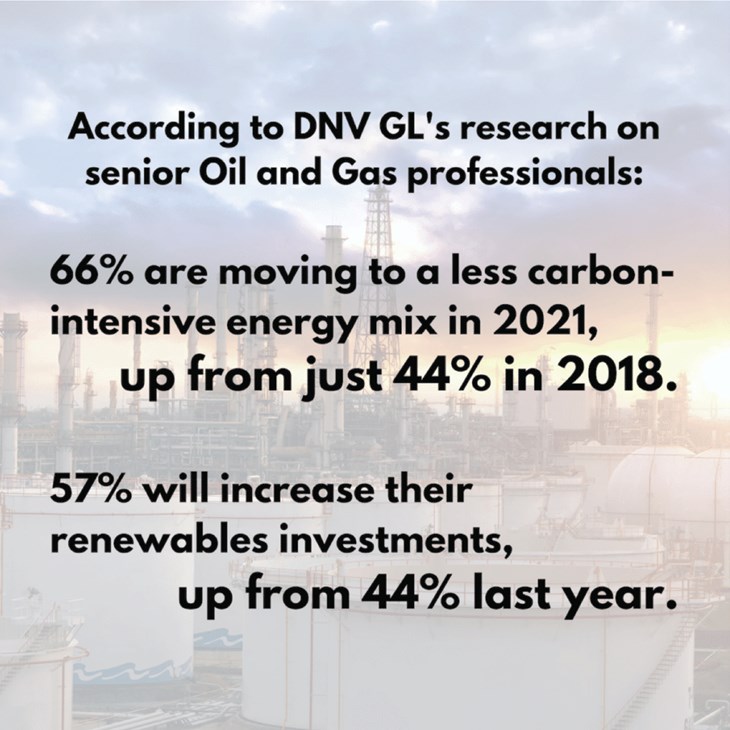

According to research by DNV GL, the Oil and Gas sector is expected to boost future energy system investments this year, as many of the key players seek to make a sustainable transformation for the coming years. While Oil and Gas is largely criticized for greenhouse gas emissions, many of the current technology options to lower the economic impact of the industry are very costly. To lower these premiums and make clean technology available across the Oil and Gas sector by 2050, current technology is in need of innovation.

Innovation often comes with an added risk or cost, but these costs are often short-term, especially when long-term benefits are generated. Companies and investors who take these risks are fulfilling their duties in the effort to make climate progress, because eliminating the Green Premium is essential to the adoption of environmentally friendly technology.

Fighting Fugitive Emissions with Control Valve Technology

Globally, public concern over the climate has never been higher. The fastest route to curtailing the global climate crisis would be to dramatically cut CO2 and methane emissions from the energy and oil & gas sectors, with simple and cost-effective technology. This is why many companies within the industrial sector, continue to deploy and test new, clean technologies. By continuing to adapt and maneuver upcoming regulations and guidelines for our climate, each industry can play a crucial role in reaching net zero by 2050.

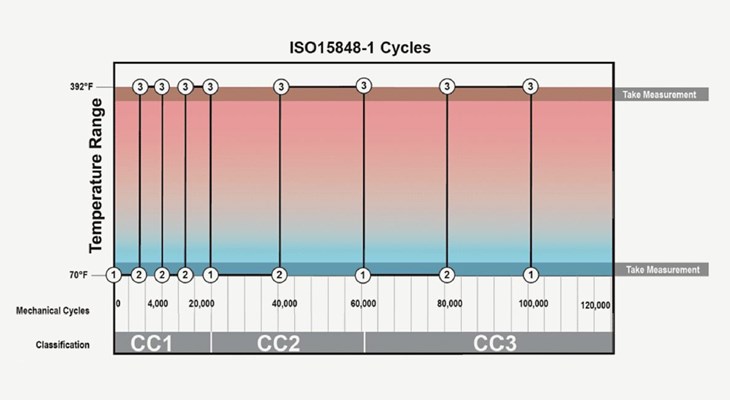

Clarke Valve’s Shutter Valve records a methane leakage rate of only 2 parts-per-million (PPM) under the ISO 15848-1 standard, compared to around 500ppm recorded in conventional globe valves. In addition to virtually eliminating fugitive emissions, the valve requires less torque to open and close, making it more energy efficient when running, and allowing the valves to be powered by off-grid renewables in some cases.

Reducing Environmental Footprints

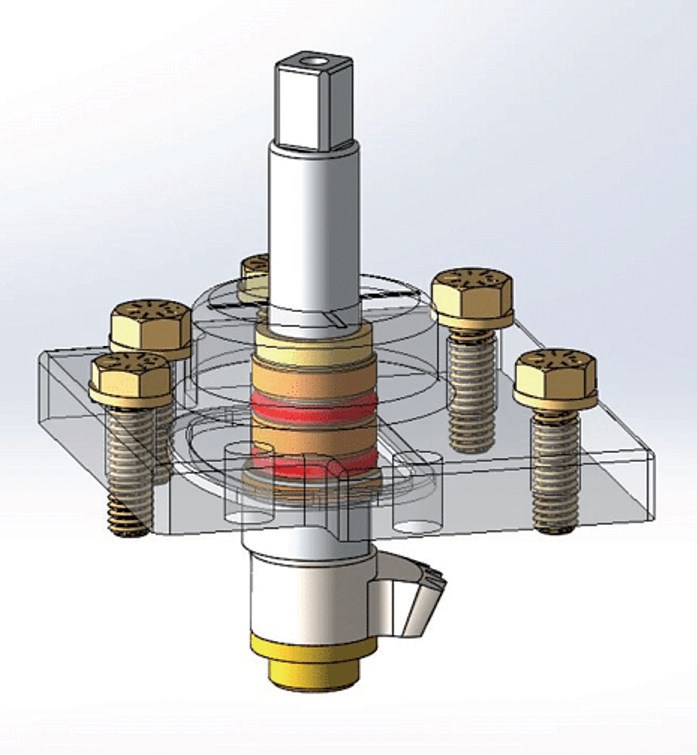

To better serve partners and customers in the Oil and Gas industry while fulfilling the company’s goals to play a role in climate progress, the Shutter Valve™ was engineered to reduce emissions in the stem-seal interface with a patented series of stem seals.

Previously, near-zero leakage in an operating valve has only ever been achievable with a bellows seal, which can be very costly and complex to maneuver when maintenance is required. The unique and patented stem-seal technology has made zero-leakage possible within a simplified and affordable system.

Though it may not currently be possible to eliminate the Green Premium across all sectors, providing green, cost-effective technology to the Oil and Gas sector is a key step on the journey to a more sustainable and clean industry.

ABOUT THE AUTHOR

Kyle Daniels, President & CEO of Clarke Valve, is an aerospace engineer and the inventor, chief engineer and head of product design of the Shutter Valve. He holds several patents on the Shutter Valve and is an expert in the fi eld of industrial valves. Mr. Daniels spent his career in the aerospace industry working at General Electric, Pratt & Whitney, and Embraer Aircraft. He is a graduate of The Ohio State University’s prestigious Aeronautical and Astronautical Engineering program, and also received a master’s degree (magna cum laude) from Brown University’s Program in Innovation Management and Entrepreneurship. Mr. Daniels is from Miami, FL and has resided in Ohio, Connecticut, Rhode Island and Paris, France.