The novel use of plastics in shock — utilizing a low tensile yield strength polymer in valve seats under high impact load.

By Jill Lawton – Senior Engineer – Flowserve

As global uncertainties rise and armed conflicts evermore in the news, a recent project by Flowserve for maritime defence isolation valve applications put them in a key position to support Operators meeting increasingly arduous requirements.

Flowserve’s Worcester floating ball valve products can be custom engineered to suit specific technical, and reliability demands of surface ships and submarines.

So, when a long serving defence customer brought a complex design requirement to be solved in a tight timescale, the Worcester Ball Valve Engineering team based in Haywards Heath, United Kingdom, were ready to take on the challenging project.

Following the Operators’ revised risk profile, the OEM needed to make a legacy platform withstand a higher shock load than its original design (where shock is very sudden and significant acceleration that can cause extensive damage).

In scope was a broad range of actuated Worcester isolation valves.

In collaboration with the customer, complete actuated legacy valve assemblies were shock tested at the enhanced shock level, which resulted in valve failures due to through-seat leakage. The root cause of this leakage was permanent deformation of the PTFE seats during the shock event.

This failure mechanism had to be designed out to protect the essential performance served by the Worcester isolation valves. Since this applied to legacy platforms, spatial envelope constraints mandated actuators no larger than those used on the legacy assemblies, and the solution had to be retrofittable and cost effective.

To guarantee the first batch of enhanced valves would be onsite for the maintenance window, the upgrade had to be designed, analyzed, tested, and customer verified within nine months. The engineering team brainstormed various concepts to eliminate post shock leakage. Considering the cost, retrofit, and timescale constraints, enhancement of the valve seats was the Prime Candidate.

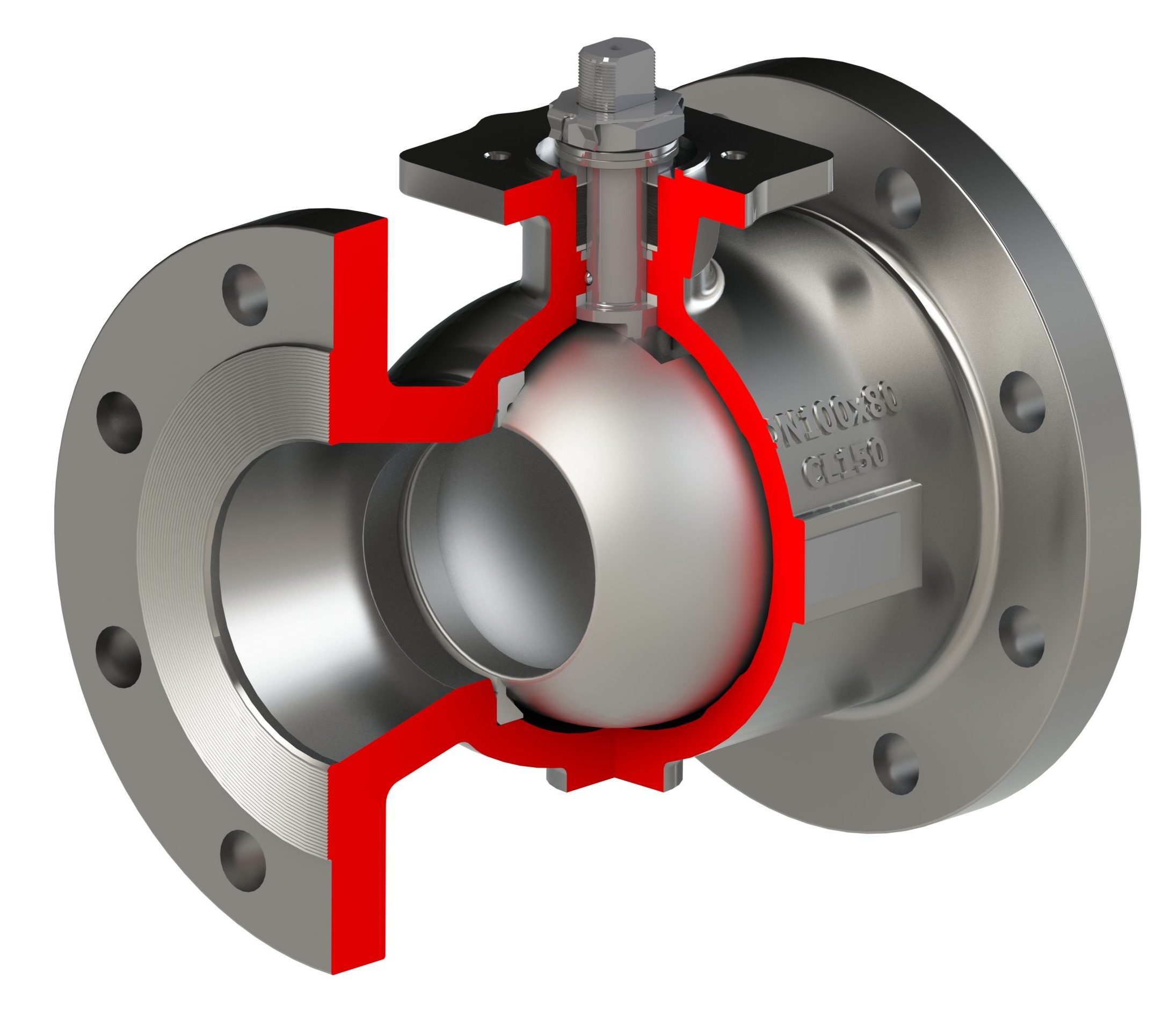

Floating ball valve seats are typically one-piece polymer designs, where material selection is influenced by numerous variables, including line media compatibility, operating temperature, and operating torque expectations. For this application, it was crucial for the ball to be in contact with a PTFE-based polymer to meet the original operating torque throughout normal conditions.

This would facilitate the use of the originally supplied actuators. The objective by the Worcester team was to house the PTFE element within a resilient polymer housing, carefully engineered to absorb energy and protect it during shock loading conditions (see figure 2).

Figure 2: One piece PTFE seat photo and cross section showing the ball, seat, and valve body.

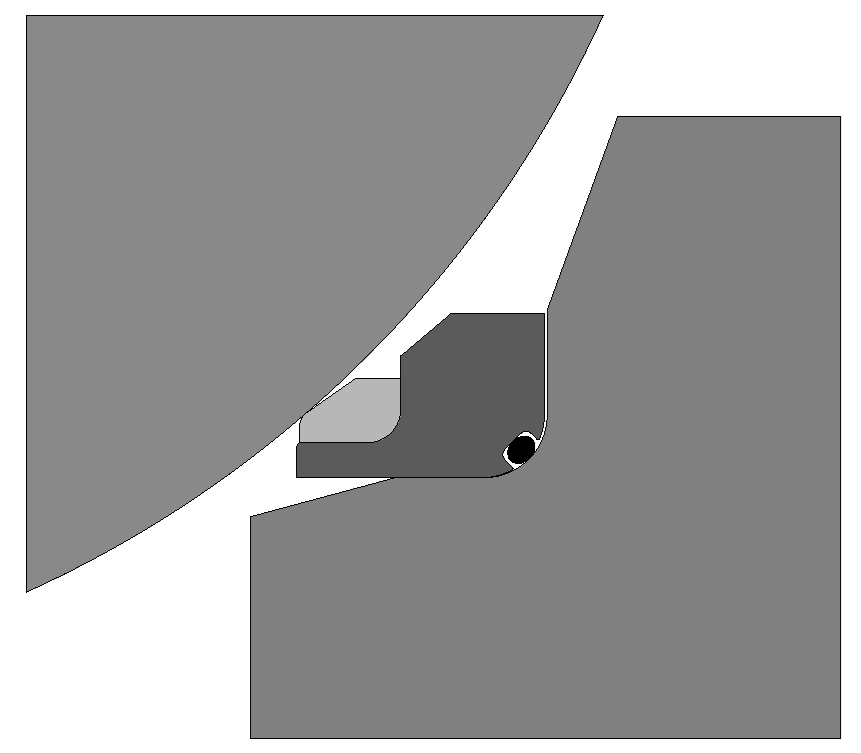

During normal operation, a floating ball valve is reliant on elastic deformation of the seat to provide the bubble- tight seal to the ball. Low pressure sealing depends on the compressive force applied during assembly to the ball and seat ‘stack.’ This is achieved by building the components into a cavity shorter than their combined height (see figure 3).

At higher operating pressures, it is the line pressure itself that causes the valve to seal. Since the pressure differential increases, the ball ‘floats’ and is forced into the downstream seat forming the seal.

To enable the ball ‘float,’ it is restrained only by the seats, which is not a concern during normal operation. However, in a shock event, the seats will absorb all the inertial energy from the valve ball acceleration resulting in unwanted permanent deformation.

It is the preservation of this floating mechanism in normal operation and protection from shock impact that must be achieved by the resilient polymer housing.

Figure 3: Two-piece or hybrid seat photo and cross-section showing the ball, hybrid seat, and valve body.

The defence industry is very attuned to safety critical applications and actively seeks tried and tested solutions to mitigate risk to assets and personnel. With history of supply into defence applications, Flowserve engineers assessed multiple polymers used throughout similar applications to test for a resilient housing. Material testing was commissioned for the shortlisted polymers to enable comparison, along with PTFE to act as a baseline.

Design of the housing was completed by the engineering team. It was further refined using Finite Element Analysis (FEA), improved via the use of the material test results to provide accurate mechanical and physical property data within the FEA software.

When the FEA results indicated the design and material combination could withstand the highest shock, physical testing of the seat prototypes could begin.

The project roadmap had highlighted the requirement for physical testing. Given the tight timeframe, shock testing a full valve assembly for each seat design iteration would not be feasible. Whilst the material selection and seat design was in progress, a parallel design task for the engineering team was set in motion for a bespoke test rig to simulate the seat shock in the worst case orientation.

The test rig only required new prototype seats for each test run and concept seat designs could be manufactured and tested with the results analyzed by the design team — all within the same day.

Outcomes of the physical testing corroborated the results acquired from the FEA, validating the approach and enabling greater refinement of the geometry and understanding of the mechanisms at play.

Having settled on the optimal hybrid seat design, which was proven to seal post shock using internal testing methods, a full assembly was prepared with the new seats and shock tested at the customer’s facility. Flowserve Engineers and the OEM were delighted to find that the valve operated at the original torque level and maintained the bubble-tight seal post shock, all achieved within the nine-month timeframe.

These test outcomes coupled with the OEM and Operators’ familiarity with seat replacement during routine maintenance, meant that Flowserve was able to proceed to design seats across the full valve size range in scope, for implementation throughout the legacy platform.

The investigation and solution delivered by the Worcester Engineering team enabled the customer to extend their platform beyond the original specification and for Flowserve to expand their knowledge and in-house test capabilities. As the owner of the hybrid seat design, Flowserve was granted a patent for the innovation and can offer the solution to all customers with demanding shock requirements.