A robust valve technology technology program in the oil, gas and chemical industry is an important element of meeting the Process Safety Management criteria. It will deliver production reliability, process efficiency, personnel protection and will help to avoid devastating process safety incidents. However, manually operated on-off valves, also called block valves, can be easily overlooked in process safety management (PSM). The same is true for check valves, which are installed in a piping system to prevent backflow, or to only allow fluid flow in one direction. As a result, there are numerous incidents in the petroleum and chemical manufacturing industry where this oversight has had catastrophic consequences.

Part two of this article addresses valve selection considerations. It showcases real world applications and scenarios, highlighting vulnerabilities leading to process safety incidents if it is done incorrectly.

By Daniel DeVine, Vice President, Design Engineering – Midland Engineering Ltd.

Potential Improper Valve Selection

The need for strong Variance and Management of Change work processes is demonstrated by design errors that have occurred, and that have been prevented when appropriate technology reviews take place. The primary basis of valve mechanical integrity is material selection. This is established in the original design code parameters. When a valve needs to be replaced, a work process is needed to identify or specify it. If the valve is a like-for-like replacement this should satisfy mechanical integrity principles (when the age of the valve is within the normal scope of life expectancy).

If there is not an exact match available, the situation requires a technical review.

Consider what can happen if this does not occur. Examples , where mechanical integrity gaps can cause a failure, are the following:

Scenario #1

i. Overview

A carbon steel body valve has failed due to corrosion. A suggestion is made to upgrade to stainless steel because it has better corrosion resistance to the service.

ii. Design Consideration:

While this is true for the corrosion component, the strength of the different materials needs to be evaluated.

iii. Technical Review:

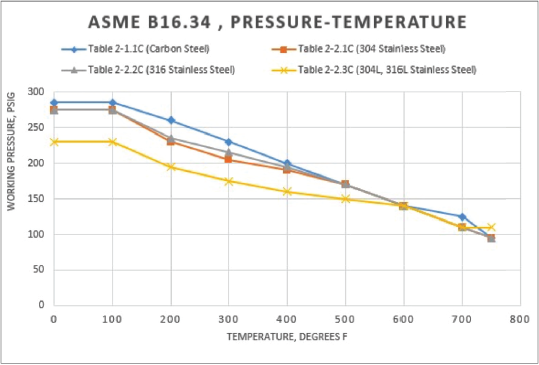

There are four material comparisons, one carbon steel, and three stainless steels, listed in Figure 5, using values from ASME B16.34. Stainless steel materials mostly have a lower pressure rating, and in the case of the L grade material, it is significantly lower.

iv. Information required/Resolution:

The suggested replacement valve can- not be put into the piping system with- out knowing the entire service conditions. Otherwise, the weaker rated valve could be placed into an overpressure situation and fail. A similar situation can occur when a material is unlisted.

Scenario #2

i. Overview:

A nickel body valve is needed in a piping system to replace a valve. This is a direct replacement. A cast nickel body valve is readily available from the valve distributor, but it is made by a different manufacturer.

ii. Design Consideration

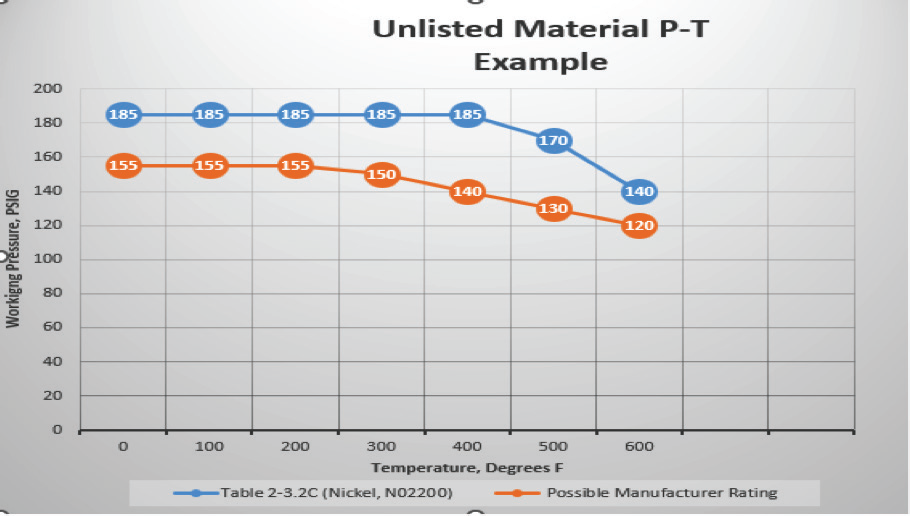

The nickel that is listed in ASME B16.34 is the wrought material B 160 Grade N02200. Cast nickel valve body material is A494 CZ100, UNS N02100, and is not listed in ASME B16.34.

iii. Technical Review:

Unlisted material indicates there is no pressure-temperature rating requirement to which a manufacturer must design their valve body. Some manufacturers may choose to meet the rating in ASME B16.34 Table 2-3.2C. Others do not meet it; they may have their own pressure-temperature rating to which their valve is designed, see Figure 6.

iv. Information required/Resolution

This request must be evaluated for each manufacturer rating and not the valve standard rating. Otherwise, the valve can be placed into a piping system for which it is not rated, experience over-pressure, and lead to failure. This also demonstrates the benefits of having an Approved Manufacturer List for valves, as these evaluations can be done in advance for each manufacturer.

Scenario #3

i. Overview:

A valve with a Hastelloy C body has failed, and a replacement is needed immediately. A valve with a Hastelloy B body is available, and it matches the size and face-to-face dimension of the Hastelloy C body valve.

ii. Design Considerations:

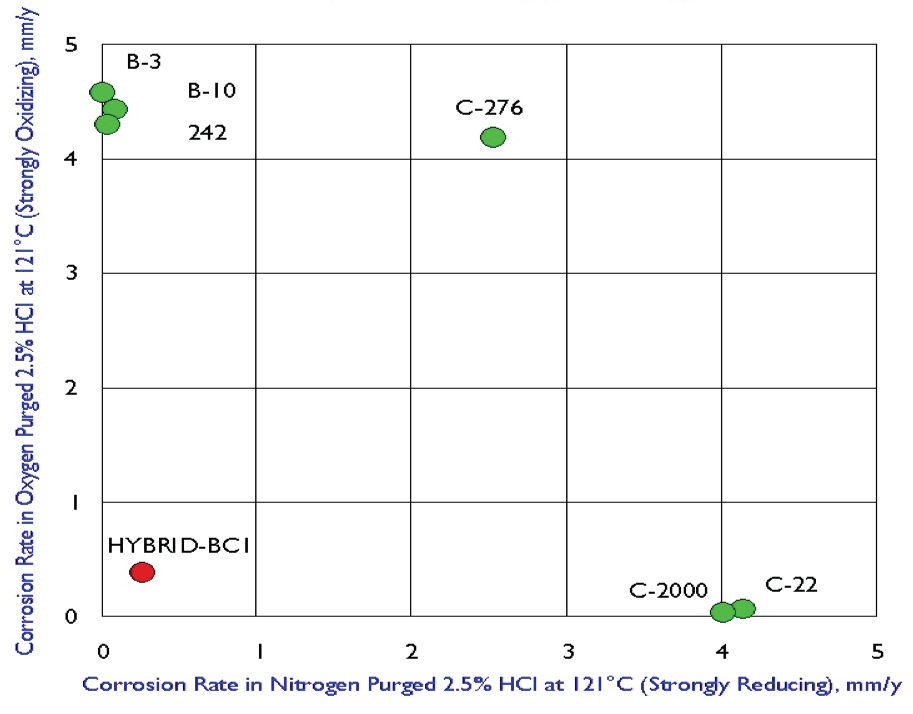

Both materials are listed on the same Table (2-3.15C) in ASME B16.34, this means they have the same pressure-temperature rating, and will meet that service condition. However, the composition of these two materials is very different, which means they have very different corrosion resistance properties.

iii. Technical Review:

A materials engineer or metallurgist needs to be involved in the design review to determine the compatibility of the Hastelloy B material and the process fluid. Certain Hastelloy grades perform well in reducing services, while others perform well in oxidizing services. This needs to be evaluated based on the chemical environment into which it will be placed.

iv. Information required/Resolution:

If a material of construction design review does not take place, an alloy valve may be placed into service with a process fluid that is incompatible and it can be attacked. This review must take place and be documented with a Variance and/or MOC form. Another important step to take for ensuring mechanical integrity with these valves is to use Positive Material Identification (PMI). The Hastelloy materials look similar and the alloy designation on the valve body might not be understood. The use of a PMI analyzer will stop an accidental mix- up of the two materials. This also provides a quality check on the valve manufacturer. See Figure 7 for corrosion-resistant properties of different Hastelloy grades.4

Scenario #4

i. Overview

Maintenance is replacing worn-out valves in a piping system. The valves that are available have a different valve specification/designation code, but it is a minor change. It is the bolting material holding the body of the valve together, that is different. This replacement valve is not listed in the pipe specification.

ii. Design Considerations:

Non-wetted parts must also be evaluated, in this case, the alternate bolting material. If the valve design specifies the bolting material to match the metallurgy of the valve, it could result in the use of stainless steel bolting, ASTM A193 Grade B8. This bolting material can be preferentially attacked if it is in an environment that has a high content of chlorides in the air, for example on the Gulf Coast in the U.S. An alternate bolting material needs to be used in these cases.

The same may be true for split-body ball valves, and plastic-lined ball valves. If there are ambient conditions, escaping fugitive emissions or the plastic-lined body joint does maintain integrity, the process fluid can be released into the atmosphere and attack the bolting.

iii. Technical Review

The ambient and process service needs to be evaluated for failure modes. Different bolting materials could have different allowable stresses and temperature limits. Coated bolts can have a lower temperature limit than non-coated bolts. All these conditions should be considered before proceeding.

iv. Information required/Resolution:

The non-wetted parts needed to be reviewed and properly considered when making a valve substitution. A materials engineer or metallurgist needs to be involved in this design review to determine the material compatibility and likelihood of a potential failure.

Common Themes in Valve Failures

- Lack of understanding of the technology and the potential consequences of a failure,

- Lack of adequate review process, or no work process is followed at all,

- Disregard for the value of this engineered component. ‘A valve is a valve’ mindset.

Conclusions and Recommendations

Valve technology and process safety performance is tied together. A successful and safely operated refinery or chemical plant cannot have one without the other. These highly engineered products need to be understood for the critical function they perform.

Starting with the fundamentals of having valves listed in a pipe specification, which will provide a reliable and documented installed basis, to the important aspects of proper maintenance and valve replacement needs, manufacturers must have a detailed and comprehensive program to address this challenge and inherent complexity. They must have knowledgeable technical staff to assist the production plants when deviations are requested and guide them to the correct decision. The potential consequences of misapplications need to be communicated to everyone involved in their design, installation, and operation. The information must be available for easy access to those who need to look at valve code descriptions, make new project purchases, or replace valves in existing piping systems.

Compliance with the PSM Mechanical Integrity element requires block and check valve technology to be applied correctly. An effective Management of Change and Variance work process will ensure proper implementation and can be key to safe valve operations and utilization.

References:

- Chemical Safety Board, “Chemical Safety Board Investigation No. 2016-02-I-LA,” U.S. Chemical Safety and Hazard Investigation Board | CSB. Accessed 15 February 2023.

- Center for Chemical Process Safety (CCPS), Process Safety Beacon, April 2010 – Fire Protection – Long Bolt Flangeless Valves. Accessed 15 February 2023. http:// www.aiche.org/CCPS/Publications/Beacon/index.aspx.

- ASME B16.34 -2020, Valves—Flanged, Threaded, and Welding End. The American Society of Mechanical Engineers – ASME. Source: TechStreet LLC.

- Crook et al., NACE CORROSION Conference 2008, paper # 08190