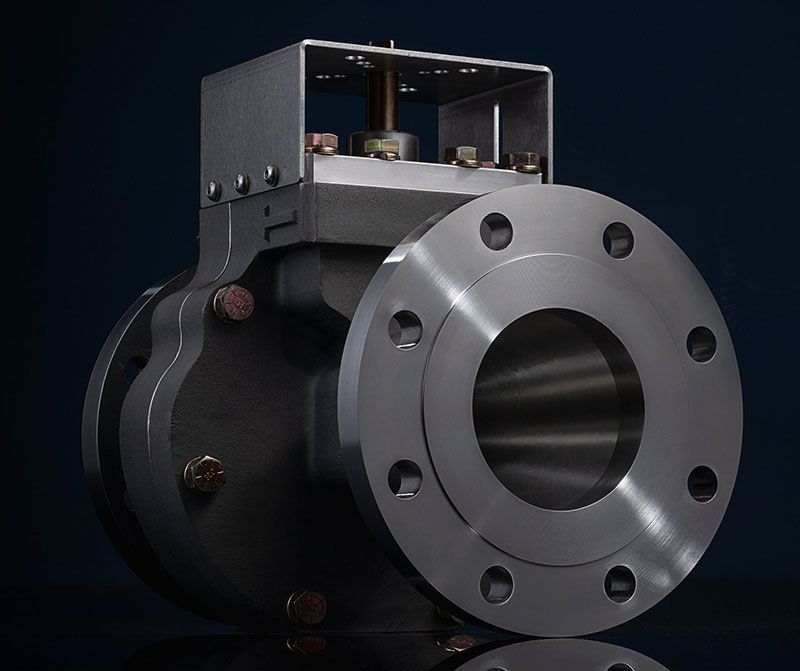

The Dilating Disk™ Valve from Clarke Valve features a unique, patented design, which provides precise flow control through the use of a three-petal mechanism. The globe valve replacement holds many key certificates and conforms to industry-required control valve specifications, including, ANSI/FCI 70-2 leakage specifications, PED 2014/68/EU, CRN, SIL 3, ISA 75.05.01, IEC 60534-1.

This control valve type also features ultra-low seat and operational torque, resulting in a significant reduction in actuator size, which leads to an easy transition to electric automation.

Clarke Valve was founded in 2011 by Kyle Daniels, who developed the technology behind the Dilating Disk™ Valve during his career as an aerospace engineer. The novel mechanism was designed as a solution for critical operational issues commonly found in aircraft valves. The last two decades have seen hundreds of design improvements, through millions of hours of testing and field experience, which have transformed it into an efficient and compact valve.

Due to its best-in-class sealing system, the Dilating Disk™ Valve is the first and only control valve to be both API 641 and ISO 15848-1:2015 certified to reduce fugitive emissions by 98%.

Courtesy of Clarke Valve.