However, it is important to understand the testing standards’ limitations before applying them to your specific application. The rising question that we will try to answer in this article is, would a certified fugitive emission valve truly meet the Low E needs with existing technology limitations?

By Asmaa Kassab, Ph.D., R&D Engineer Supervisor & David Ashwill, Engineering Technology Manager – MOGAS Industries Inc. Posted by Sarah Bradley.

Temperature Limitations in Fugitive Emission Standards

There are several standards that influence the design and performance of certified fugitive emission valves such as API 641 “Type testing of Quarter-turn valves for Fugitive Emissions” and ISO 15848-1 and 2 “Measurement, test and qualification procedures for fugitive emissions,” “Part 1: Classification systems and qualification procedures for type testing of valves” and “Part 2: Production acceptance test of valves,” however, none of these standards addresses high temperature applications above 752°F/400°C such as Delayed Coker, Fluid Catalytic Cracking, Hydrotreating, and Hydrocracking applications.

API 641 standard was designed to address approximately 80% of the refining and petrochemical applications. Although the latest edition of API 608 (January 2020) requires all metal ball valves to be fugitive emissions qualified to API 641, this standard was never intended to address all applications and certainly not high temperature applications.

Quarter-turn valves such as ball valves and butterfly valves qualified to API 641 are required to use API 622 ‘Valve Packing for Fugitive Emissions’ qualified packing. API 622 standard indicates that the packing maximum testing temperature is 500°F/260°C but their qualification goes up to twice the testing temperature or 1,000°F/538°C. Similar to API 622, API 641 standard test the valves to a maximum temperature of 500°F/260°C and does not extend a “qualification temperature,” just lists the test temperature.

ISO 15848-1 is another common standard that is more applicable for high temperature severe service valves, as it offers several classes of temperature qualification and includes testing for higher temperatures up to 752°F/400°C and does not extend the qualification above the test temperature. It is worth mentioning that ISO measures the test temperature at the center of mass for the valve body but records the temperature in the area around the packing box for information.

Table 1 shows the comparison between ISO 15848-1 and 2 and API 622 and 641 standards. In terms of testing, ISO 15848-1 is more stringent than API 622 and 641 since the maximum testing temperature is 752°F/400°C, compared to 500°F/260°C for the API standards. Currently, testing temperatures above 752°F/400°C are not considered in any fugitive emission standard.

End users are starting to realize this inconsistency and standard committees are having discussions to add an optional test to the API standard with a high temperature test for valve and packing as well as changes to the scope of the API 622 test standard to limit the qualification range up to 800°F/427°C to align more closely with the ISO standard qualification.

[1] ISO 15848-1 has several different classification criteria for classes for the allowable leakage rates, number of mechanical test cycles and test temperatures.

[2] There is a proposal for higher temperature testing.

[3] Acceptance criteria is based on the tightness class the design was tested to per ISO 15848-1.

[4] Valve must be the same basic stem and packing design.

[5] The scope of the standard is class 150 to 1500 and valves NPS 24 and smaller.

Limitations of Fugitive Emissions Packing

Typically, the packings used for API 622 qualifications contain some volume of lubricant agent such as polytetrafluoroethylene (PTFE) which has a low coefficient of friction. Although API 622 standard refers to PTFE as a lubricant agent, in reality it serves a dual purpose as lubricant and blocking agent because it significantly increases the sealing performance of the packing. Moreover, it is proven that packings without PTFE content are highly unlikely to successfully pass FE qualification testing especially when testing with helium (smaller molecule size than methane) or at high pressures and temperatures since there is a direct correlation between the sealing performance and the PTFE content of the packing. The earliest version of the API 622 standard limited the PTFE content to a maximum of about 15% by volume. However, there is no PTFE content limit in the latest edition of this standard, which now requires only that it be reported.

Even though the PTFE is widely used as a lubricant and blocking agent in packings for fugitive emissions purposes, PTFE melting temperature is 599-642°F/315-339°C and it is proven that at 750°F/400°C the PTFE gases off (sublimes) leaving no residue. Studies shows that for temperatures above 750°F/400°C, packings with PTFE content will lose between 2% and 17% in volume due to PTFE sublimation and this weight loss in the packings creates a leak path and potentially increase emission to the environment.

As a result, the qualification to fugitive emissions standards does not guarantee low emission performance valves at temperatures over 752°F/400°C because of the temperature limitations of both API and ISO standards and due to the sublimation of PTFE, present in fugitive emissions packings, at elevated temperatures.

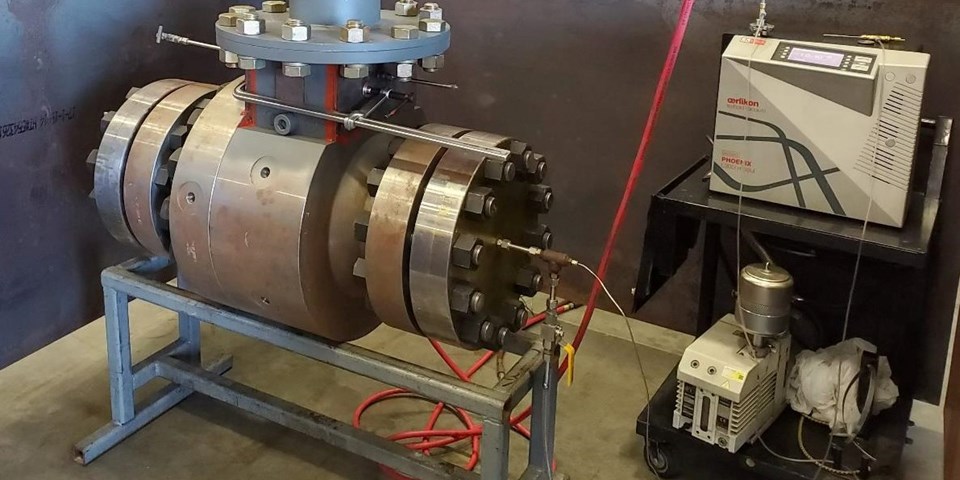

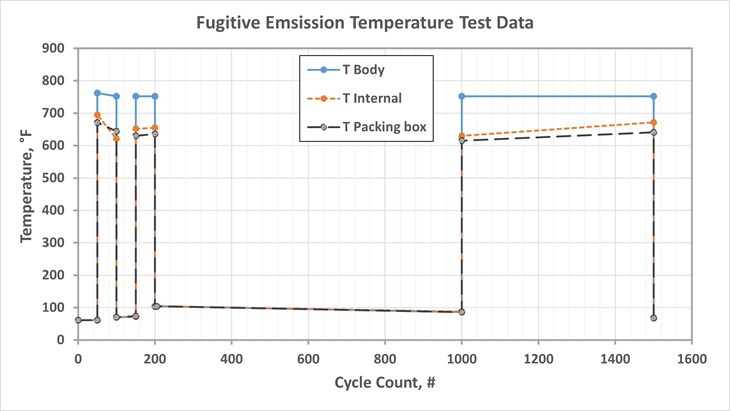

One common question end users ask is what is the temperature difference between the media and the packing? We have observed, in FE testing as shown in Figure 1, that the packing box temperature typically lags the body by a differential of approximately 100°F or 56°C as shown in Figure 2. However, in steady state conditions, the packing on some insulated heavy oils and delayed coking valves will operate at a much similar temperature than the media, which is considerably higher than the testing standards, in the range of 850°F/454°C and or above.

Valve Designs Considerations for Fugitive Emissions Service

Complying with API 641 and ISO 15848-1 standards additionally impacts valve design and performance. FE qualified valves will not be standard valves, as additional changes are required:

Higher packing compression is needed at assembly as recommended by FE packing manufacturers, this increases operating torque and potentially increases actuator size on smaller valves. In order to adequately compress the packing, more or larger gland fasteners, or higher strength bolts may be required as well as heavy gland flanges to accommodate the increased loads. This could change the design of the top works, resulting in a larger valve body to accommodate larger fasteners.

In general fugitive emission packing requires approximately twice the gland load to compress the packing to the level necessary to achieve low emissions performance (Figure 3). In order to achieve this load, a higher-than-normal gland stud torque is required below:

F=π/4 (Dpacking2 – Dstem2)*ðp

Bolt Torque, T= K*Dstud*F/N

where N is the numbers of studs

Where:

Dpacking: Packing Box Outer Diameter

Dstem: Stem Sealing Diameter

F : Target bolt/gland force

K: Friction Factor

ðp: Target Packing Stress

T: Bolt Torque

Dstud : Minor thread diameter of fastener

Recommended Solution for Low Emissions Valves in High Temperature Applications

Considering the testing temperature limitations of API 622, 641 and ISO 15848-1 FE standards and the sublimation of PTFE commonly present in FE packing, we recognize the need to develop technologies for high temperature applications that will help end users to lower the emissions at industrial sites.

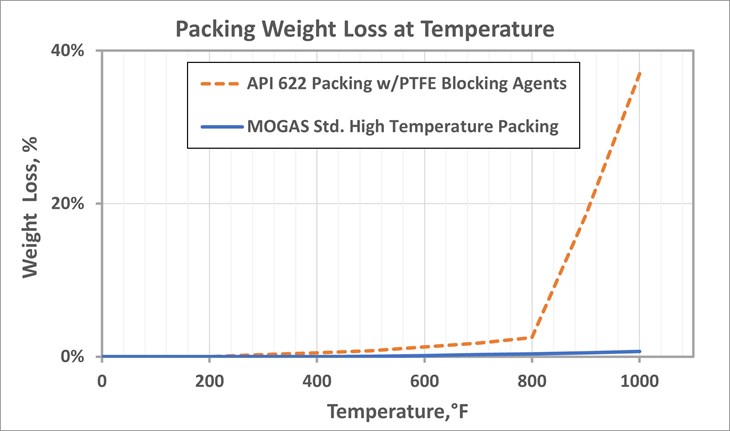

To achieve low emissions in high temperature applications, a packing with no PTFE content should be considered. Figure 4 illustrates the degradation of API 622 Fugitive Emission packing at various temperatures as compared to standard high temperature packing with no PTFE content.

As clearly shown in Figure 4, the weight loss of the API 622 Packing increases exponentially over 800oF/427oC, while the standard high temperature packing weight loss remains linear and is much lower at the actual operating temperatures of heavy oils applications since it does not contain any PTFE blocking agents. What the graph cannot illustrate is the effect of the initial packing box pressure (internal packing stress) which is required to be typically twice as high for the API 622 packing.

MOGAS can provide valves qualified to API 641 and ISO 15848-1, when required per limited scope mentioned above. However, qualification to these standards does not guarantee low emission performance at temperatures over 752°F/400°C because of the limitations of both API 641 and ISO 15848 standards. Due to the sublimation of PTFE (present in fugitive emissions packings) at elevated temperatures, API 622 packings are more likely than the standard packing to lose volume and impact the performance of the packing in higher temperature services.

Reiterating, qualification to these standards does not guarantee emission performance for valves exposed to temperatures higher than the test temperatures:

• API 641; 500°F/260°C.

• ISO 15848-1; 752°F/400°C.

In addition, class 2500 valves cannot be certified to API 641 as they are outside the scope of that standard.

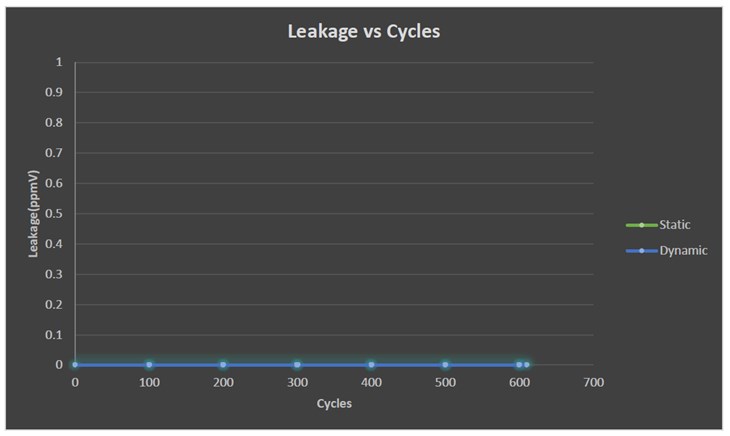

Even though MOGAS has achieved the highest API and ISO fugitive emission standards requirements (Figure 5), as a severe service manufacturer we strongly advise our customers only to use FE packing with PTFE at or below temperatures specified in the test standards.

Conclusion and Recommendations

It is important for the end users to understand their needs for low emission and recognize the limitations of existing technology. Educating customers on existing FE packing limitations is imperative. The topic of FE compliance is a complicated one and it is a topic that some manufacturers are counting on the customer not fully understanding within the complete application’s ramifications. It is important for the end users to understand their specific needs for low emission and recognize the limitations of existing technology.

It is critical to understand the difference between FE test qualifications and low emissions. The FE test qualifications are pressure and temperature limited, and it is well proven that the existing packing will degrade significantly at temperatures higher than 500°F/260°C causing even higher emission. In such instance, the requirements of FE represent a case where meeting the specification will likely result in excessive emissions from the valves that fail to meet performance expectations.

Packing manufacturers are aware of this limitation and working on the next generation fugitive emission packings not containing any PTFE, but until then it is critical to understand the limitation of existing technology.

References

- API STD 641 – Type Testing of Quarter-turn Valves for Fugitive Emissions. 1st Edition October 2016

- ISO 15848-1 – Industrial valves – Measurement, Test and Qualification Procedures for Fugitive Emissions (Part 1: Classification system and qualification procedures for type testing of valves). 2nd Edition June 2015

- ISO 15848-2 – Industrial valves – Measurement, Test and Qualification Procedures for Fugitive Emissions (Part 2: Production acceptance test of valves) 2nd Edition June 2015

- API STD 622 – Type Testing of Process Valve Packing for Fugitive Emission. 3rd Edition October 2018

About the Authors

Asmaa Kassab, Ph.D. is the R&D Engineer Supervisor at MOGAS Industries Inc. She started her career 9 years ago in control valves with MOGAS after she obtained her doctorate degrees in thermal fluid science from Texas A&M University. She leads the MOGAS Research and Development team in new and enhanced severe service products and serves as MOGAS’ subject matter expert in flow analysis, advanced testing, and the control valve product line.

A ball valve industry professional for 40 years, David has engineered API 6D, API 6A, and light industrial ball valves and actuators. Now with MOGAS for over a decade, he manages a collection of industry subject matter experts, application engineers and designers for direct technical support of MOGAS sales and service efforts worldwide. David serves as the vice-chair for MSS’ (Manufacturer’s Standardization Society for the Valves and Fittings Industry) Committee 410 Severe and Special Services Valves, as well as a member of the coordination committee for MSS.