By Robert McIlvaine, President & Founder — The McIlvaine Company

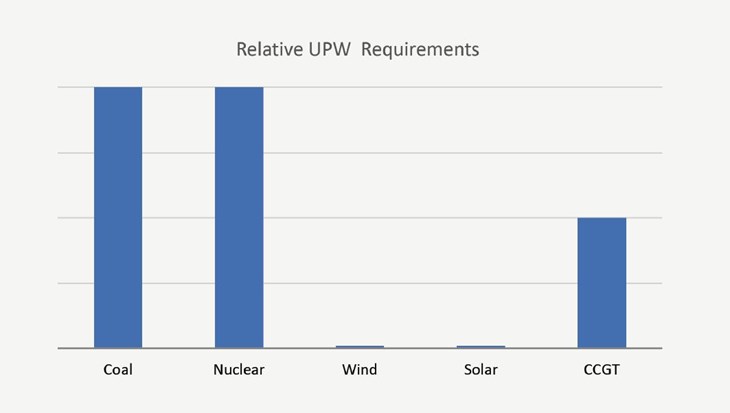

Today the U.S. coal power generation has shrunk by 40%. Nuclear generation is also falling. These two applications require far more ultrapure water than other fuels. Gas turbine combined cycle plants require only 50% as much UPW as coal plants. However deionized water can be injected into the turbine inlet to increase the mass.

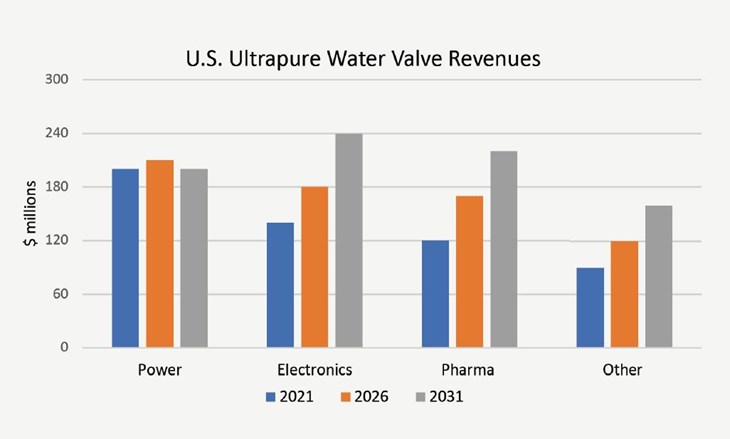

Over the next 10 years the power market in the U.S. will at first rise slightly and then fall back to 2021 levels by 2031.1

The pharmaceutical UPW valve market will grow at greater than 5% per year over the next 10 years and by 2031 will exceed USD $230 million in the U.S.

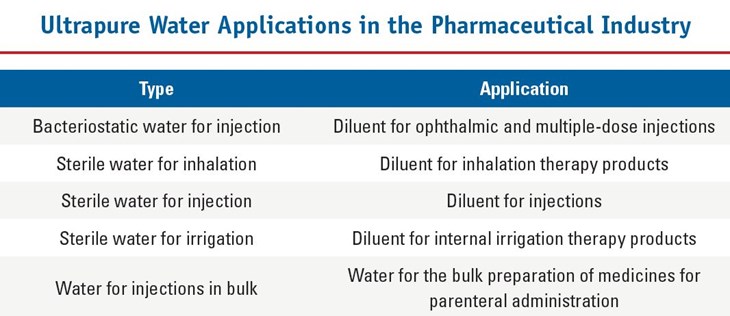

Applications in the pharmaceutical industry include water for injection plus clean steam.

The semiconductor industry has been designing the chips in the U.S. but using foundries in Asia to produce them. Due to the present chip shortage and direct impact on the U.S. auto industry there is a government led program to expand chip capacity in the U.S. Other U.S. electronics manufacturers will be expanding UPW use over the next decade.

As a result the electronics sector will be the largest purchaser of UPW valves with purchases rising to USD $240 million by 2031.

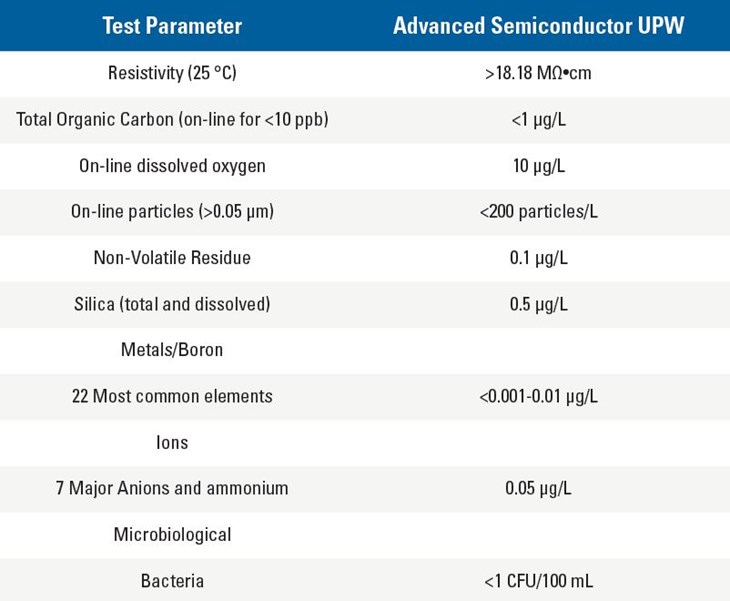

Ultrapure water is used extensively in the semiconductor industry; this industry requires the highest grade of UPW quality. The consumption of electronic-grade or molecular-grade water by the semiconductor industry can be compared to the water consumption of a small city.

A single factory can utilize ultrapure water (UPW) at a rate of 2 MGD, or ~5500 m3/day. The use of UPW varies; it may be used to rinse the wafer after application of chemicals, to dilute the chemicals themselves, in optics systems for immersion photolithography, or as make-up to cooling fluid in some critical applications. UPW is even sometimes used as a humidification source for the cleanroom environment.

The primary, and most critical, application of UPW is in front-end cleaning tools, when the foundation (transistors) of the integrated circuit is created. For use as a cleaning and etching agent, impurities which can cause product contamination or impact process efficiency (e.g. etch rate) must be removed from the water.

UPW is used in other types of electronics manufacturing, such as flat panel displays, discrete components (such as LEDs), hard disk drive platters (HDD) & solid-state drive NAND flash (SSD), image sensors & image processors/wafer-level optics (WLO), and crystalline silicon photovoltaics.

The cleanliness requirements in the semiconductor industry for advanced chips are currently the most stringent.

Because the U.S. is the leading supplier of pharmaceuticals and because of a rejuvenation in the semiconductor industry, the market will be strong for the next decade.

REFERENCE

(1) Industrial Valves: World Markets published by the McIlvaine Company

ABOUT THE AUTHOR

Robert McIlvaine is the CEO of the McIlvaine Company which publishes Industrial Valves: World Markets. He was a pollution control company executive prior to 1974 when he founded the present company. He oversees a staff of 30 people in the U.S. and China. http://www.mcilvainecompany.com