Honeywell company, UOP LLC has been chosen to provide technology for propylene production by the Dow Chemical Company at a Texas production site. A new propane dehydrogenation unit will use Honeywell UOP(3) Oleflex technology to turn shale gas propane into propylene. 750,000 metric tons of polymer-grade propylene will be produced by the site annually, a product used in making adhesives, coatings, cleaners and packaging. The first of its kind in the United States and North America’s largest single-train propane dehydrogenation plant, the site is planned to start up in 2015.

Honeywell company, UOP LLC has been chosen to provide technology for propylene production by the Dow Chemical Company at a Texas production site. A new propane dehydrogenation unit will use Honeywell UOP(3) Oleflex technology to turn shale gas propane into propylene. 750,000 metric tons of polymer-grade propylene will be produced by the site annually, a product used in making adhesives, coatings, cleaners and packaging. The first of its kind in the United States and North America’s largest single-train propane dehydrogenation plant, the site is planned to start up in 2015. “There is a unique opportunity in today’s market where shale gas development is driving lower prices and greater availability of propane as a feedstock for petrochemicals,” said senior vice president for Process Technology and Equipment at Honeywell’s UOP, Pete Piotrowski.

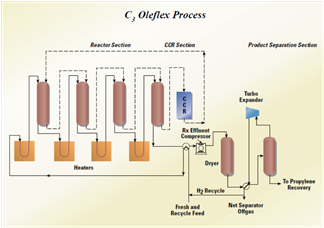

Oleflex technology offers the lowest production cost and highest investment return in comparison to alternative processes. The process uses UOP CCR continuous catalyst regeneration technology to dehydrogenate over a platinum catalyst and requires low capital and operating costs, minimum plot area requirements, high propylene yield, high operating flexibility and premium scalability. Honeywell’s UOP has consigned nine C(3) Oleflex units since the technology went commercial in 1990. A 10th unit is set to start up in Russia in 2012.