The chemicals industry is so vast – ranging from petrochemicals to pharmaceuticals, fertilizers and numerous other areas – that generalizations are difficult. However, the sector as a whole appears to be in good shape, with most indicators pointing to strong and upward growth. In March of 2017 the American Chemistry Council published figures showing 5.5 percent production growth over one year, with growth of 0.5 percent in March alone). Breaking it down into regions and countries, we see a varied picture, with Belgium growing by a staggering 12 percent and Sweden lagging with -10 percent.

Overall, Europe posted healthy growth, especially in the eastern and central regions. North America had a sluggish year, while Latin and South America suffered negative growth. In Asia, growth is strong, with China playing a dominant role and South Korea and Japan especially dynamic. The industry is also undergoing a shake-up, with a surge in mergers and acquisitions approaching.

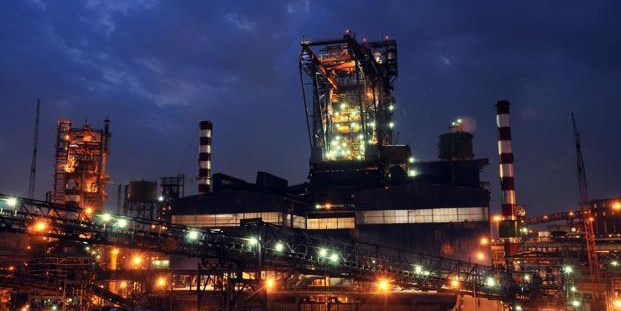

China Remains Dominant

Despite slower growth, China’s dominant role remains unchallenged. There are over 140 chemical parks, and the government is focusing on seven of them; several major petrochemical projects are planned. The BASF/Markor partnership started up a new plant in July last year, and BASF is building a plastic additives plant in Shanghai. SABIC has agreed to build a coal-based petrochemical complex. Rongsheng is planning a plastic bottle factory for 2018, Sinopec is boosting capacity at its fine chemicals plant at Maoming, and a hydrocracking plant for Gazprom was recently announced. September 2016 saw the launch of the Far-Eastern Petrochemical Company (FEPCO), a joint venture between Rosneft and ChemChina. The rest of Asia is also bristling with activity. BASF opened its first plant in Sri Lanka to produce construction chemicals and is expanding production capacity for specialty plastics in South Korea. In December of 2016 the German chemicals giant announced plans to build its first plant in Myanmar. India saw the opening of an additional plant for automotive emissions catalysts, while KBR is revamping its ammonia plant at Panambur, Mangalore. In Malaysia, Petronas is planning a refinery and petrochemicals complex, while Thailand’s IRPC announced it will expand its petrochemical capacity.

BASF’s Acetylene Plant

In Europe, one of the biggest projects is BASF’s acetylene project at Ludwig- shafen. The plant will start up at the end of 2019 and replace the existing plant. It will serve around 20 production sites at the Ludwigshafen facilities. The company is also teaming up with Avantium to produce furandicarboxylic acid (FDCA), a bio-based chemical. In the UK, Swedish plastics engineer Trelleborg has opened an applied technologies facility in Retford, Nottinghamshire, to grow its polyurethane manufacturing capabilities. In Russia, Lukoil opened its largest vacuum gasoil hydrocracking unit in Volgograd. In North America, the shale oil and gas industry has resulted in several methanol and ethylene projects. Up to six ethane projects are expected to come online in 2017, and another ten are being considered. Several new facilities are planned. For example on the Gulf Coast, Exxonmobil will spend 20 billion USD over ten years on refineries, chemical and LNG projects and is planning a multi-billion dollar petrochemical complex in partnership with SABIC.

Saudi Arabia Opening Up

In the Middle East activity is mainly focused in Saudi Arabia, where SABIC, which has just started up a rubber factory, is considering a petrochemicals project with Saudi Aramco that would convert crude oil directly into chemicals without manufacturing naphtha. The Saudi kingdom is also opening up to foreign companies: the first to acquire a trading license was Dow, which is exploring opportunities across a range of industries. Also expected to flourish is Iran–though this depends on whether the lifting of sanctions is definitive. In October 2016 Shell signed an MOU with the country’s National Petrochemical to work on joint projects. Indeed, the country is seeking foreign investment to build 25 petrochemical plants. Algeria announced tenders for four petrochemical plants and had received 49 offers from international firms by February 2018.

IKEA’s Focus on Renewables

Breakthroughs in chemical technology have the potential to transform the way we generate energy and make things. Among the most interesting recent developments are (1) bio-based chemicals, (2) energy reduction in chemical processing and (3) breakthroughs in catalysis technology.

Bio-based chemicals use organic material, rather than crude oil or oil derivatives, as feedstock. For example, the BASF Avantium partnership produces furandicarboxylic acid (FDCA) from fructose; from it is derived a new polymer, polyethylenefuranoate (PEF), used in bottles and home care products. The University of Bath is investigating biochemicals such as pinene, a waste product from papermaking derived from pine trees, which could replace caprolactone; and limonene, from citrus fruit, which could replace petrochemicals to make plastics or pharmaceuticals.

Bio-based chemicals are getting a big boost from the likes of Lego and IKEA, which wants to manufacture all its plastic products–including carrier bags, toys and storage boxes – from renewable and/or recycled materials by 2020.

Less Energy-Intensive Production

If the development of bio-based chemicals is being driven by the idea of sustainability, the same holds true for efforts to harness chemical processes to reduce energy and water consumption. Wastewater management is one area receiving a lot of attention.

GE is running a project with Canada’s Southern Ontario Water Consortium to use biological hydrolysis technology to enhance anaerobic digestion to produce not only clean water but also renewable energy and fertilizer. Scientists are on the look-out for ways of producing reactions at room temperature rather than at the very high temperatures and pressures that consume lots of energy.

The University of Utah, USA, has developed a process that could replace the energy-intensive Haber-Bosch process used in ammonia production. This is an enzyme-driven fuel cell process, which can generate ammonia at room temperature and produce a small electric current. Another holy grail is an inexpensive way of splitting water to produce hydrogen. Researchers from Cambridge have found a way to extract pure hydrogen from biomass using only alkaline water, sunlight and nanocatalysts. The process takes place at room temperature and is therefore less energy-intensive than traditional ways of converting biomass into hydrogen.

More Efficient Catalysts

This brings us to catalysis, an area, which is currently receiving lots of attention, as scientists vie to find quicker, more efficient catalysts using less rare and expensive metals. The pace of innovation is so fast that scientists can hardly keep up. A major challenge is to find alternatives to the more expensive metals such as palladium, platinum, ruthenium and iridium.

Instead, scientists are looking to the likes of iron, nickel or copper, or are trying to dispense with metals altogether. Nickel is especially sought after as it has similar properties to palladium and platinum. In 2016 scientists at Missouri University of Science and Technology demonstrated a new nickel selenide catalyst for more efficient water splitting. At the Federal Institute of Technology in Lausanne, scientists are working on a complex based on a nickel ion. One such catalyst is already available and others are being developed. More recently, a nickel catalyst was developed that converts the tough lignin from the grass Miscanthus into phenolic compounds that can be used in flavor or fragrance chemistry.

However, these developments do not mean that traditional metals are on the way out. Scientists at Yale have developed a technology for reducing the amount of palladium required in a process, and a way has been found to use platinum catalysts to produce hydrogen. In short, there are more than enough technological challenges for the chemical industry to produce more energy efficient and with higher conversion rates.

MATERIALS

Chemical processes are notoriously corrosive because of the acidic conditions. Especially when these are allied with high temperatures and pressures, material selection for equipment (piping, pumps, valves et cetera) can be a challenge. Alloys of nickel, zirconium and cobalt are the core materials used in the severest conditions. Nickel alloys are required in environments that contain aluminium hydroxide, chlorine, ethylene, hydrochloric or sulphuric acid or sodium hydroxide. Hastelloy, Inconel, and Monel are all groups of CRAs used in chemical service.

A relative newcomer is Hastelloy HYBRIDBC1, a Ni-Cr-Mo alloy with enhanced resistance to hydrochloric and sulphuric acids, without the drawbacks of the Ni-Mo and Zr materials.

Bio-based chemical processing is a process involving fermentation. It is a relatively new field for which material specification has not yet become standardized. Organic acids are the main corrosion challenge, along with aqueous carbonic acids, chlorides etc., depending on feedstocks.