Hybrid CNC Parts has expanded its advanced manufacturing capabilities with the purchase of two additional Phillips Additive Hybrid Laser-Wire systems.

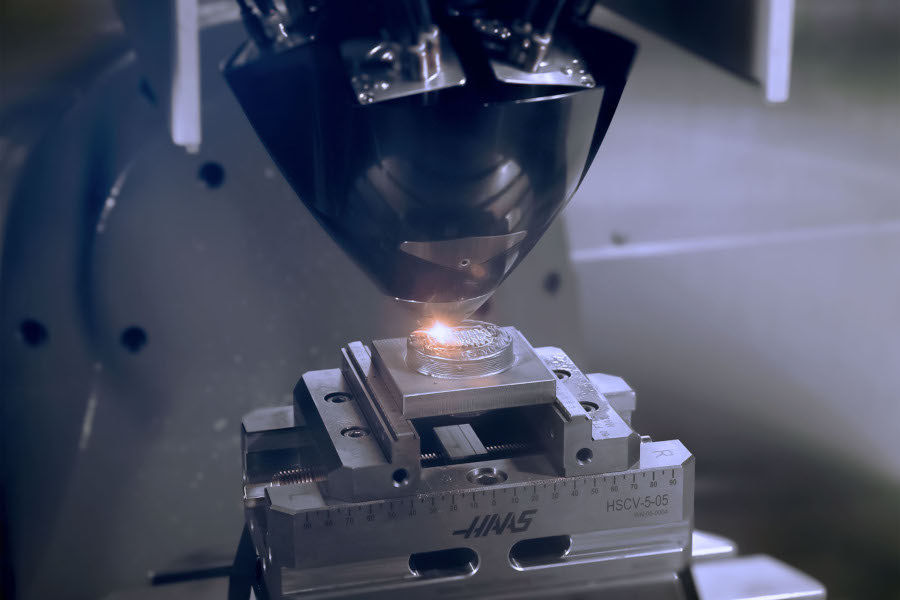

Powered by Haas and Meltio, the investment triples the company’s Hybrid capacity. As a result, the systems will enable greater flexibility, redundancy, and throughput for its customers. It will also provide increased precision during metal additive and subtractive manufacturing in a single location.

The new machines strengthen Hybrid CNC Parts’ ability to serve industries such as aerospace, defense, and advanced R&D. These are sectors that increasingly require rapid prototyping, repair, and small-batch production of complex metal components.

Hybrid CNC Parts is a Hybrid job shop and design-for-hybrid engineering firm, bridging the gap between digital design and production. Its engineers specialize in optimizing parts for hybrid manufacturing — balancing additive and subtractive processes to achieve superior performance and cost efficiency.

Courtesy of Hybrid CNC Parts.