A few valve companies are achieving EBITDA (Earnings Before Interest, Taxes, Depreciation, and Amortization) of thirty percent. However, the average is less than fifteen percent. Profits are steady and predictable. Over the next ten years the industry will be transformed in ways which we can only predict.

By Robert McIlvaine, Founder and CEO – The McIlvaine Company

This transformation will occur due to the following:

- Major impact of artificial intelligence

- Double digit growth in AROM (Automation, Remote Operation and Maintenance)

- The weaponization of the ‘Industrial Internet of Wisdom (IIOW)’

- Competition between valve, automation, and system suppliers

AI experts are telling us that the technology will profoundly change our lives in the next ten years. The valve industry will be impacted more than most because high efficiency pattern recognition is well suited to control flow. We are moving towards a time when owners will rely on third parties to operate and maintain their process systems, and these systems will be producing better and safer products. They will prove fertile ground for developments in AROM. This creates an enticing opportunity for third parties.

Presently, valve companies generate a third of their revenues from products and services other than valves and parts; these can be lumped together and called ‘support’. It includes smart valve systems, service, remote advice, valve performance monitors, and various automation components such as actuators and positioners. The Industrial Internet of Wisdom results from adding valve expertise to IIOT. The greater the extent that artificial intelligence is used in automation systems, the greater the need for niche personal experts.

For example, a valve performance monitor provides tremendous amounts of information that AI can utilize in guidance. But how that guidance specifically applies to a niche situation is best determined by a niche expert. The more robust the AI system, the more need for expertise in smaller and smaller niches.

Over the next ten years we are predicting that support revenues will grow at double digit rates. The valve support revenues captured by valve companies will be only a fraction of valve support revenues in total, the remainder will be captured in competition between the automation and process system companies. The pitfall of IIOW will determine the market share for the valve companies versus the automation and system suppliers.

Information, such as that generated by performance monitors, will be critical to demonstrating lower total cost of ownership. This means the companies controlling IIOW have a better chance of success than the opposition. The data is not only used to prove the product is superior but to uncover problems or changes that can make the product better. IIOW will be utilized to impact margins for valves and parts. If an automation company has more information than the supplier on how a valve is operating, it can dictate product changes and seek lower prices from the supplier.

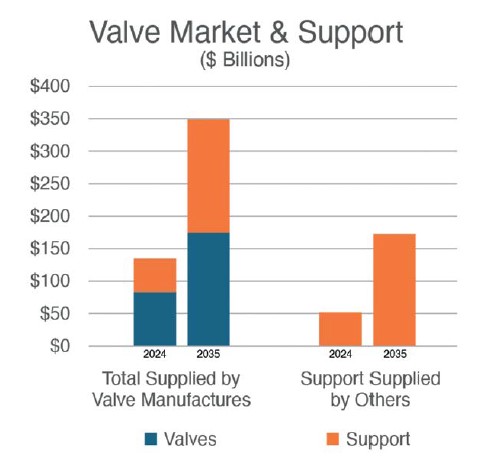

Valve focused profit centers will generate revenues of $132 billion this year. Valves and parts will be $82 billion and support $50 billion. These companies will capture one hundred percent of the valve and part revenue but only fifty percent of the valve AROM support revenues. The high profit-high risk nature of the valve industry is shown in the example below:

In 2035 the total support revenue will be $345 billion, of which valve focused companies are slated to capture fifty percent. The high profit and high risk are obvious when you consider that the support revenue in just ten years will be two times the total revenue for valve focused companies today. How likely is it that the valve companies capture fifty percent of the support market? What if the automation and system companies capture seventy-five percent of the market? Also, relative to valve competition, this changed environment will lead to changing market shares.

The weaponization of IIOW will be a deciding factor; valve companies are well situated to lead due to their extensive technical expertise. For example, consider the present initiatives to reduce fugitive emissions of refinery valves. Rising stem ball valves are being replaced by diaphragm valves, with the new designs greatly reducing the emission risks. This valve improvement can lead to regulatory changes.

Presently, California requires perimeter monitoring continuously for multiple pollutants. This is expensive and many times the cost of the valves. If valve companies can stop the leaks and employ performance monitoring to ensure continuous compliance, the refineries can then seek relief from this very expensive perimeter monitoring. This is a good example of the pitfalls of IIOW.

In this new world, there will be various partnerships and collaborations. The valve company is clearly in the best position to develop the performance monitor. It can be tailored to the specific valve. The automation company can argue that, while its performance monitor may not be quite as good as one specific valve type, what is in fact important is the seamless integration. Thus, they would say it is better to use the performance monitor of the automation company.

A hybrid solution may be the answer. The valve company performance monitor is slightly revised to be integrated into the supplier automation system. Arrangements are made for the valve company to be paid for service expertise in addition to a yearly license for the monitor. Collaboration with systems suppliers is very promising, promising to combine process and valve expertise. The market is thus now high risk and profit.

We are in an environment where there will be new market leaders. There are big downside risks, but the one good bet is that the IIOW will be weaponized more fervently by those who have the greatest success.

REFERENCE

McIlvaine Valve Focused Profit Center Market Guide