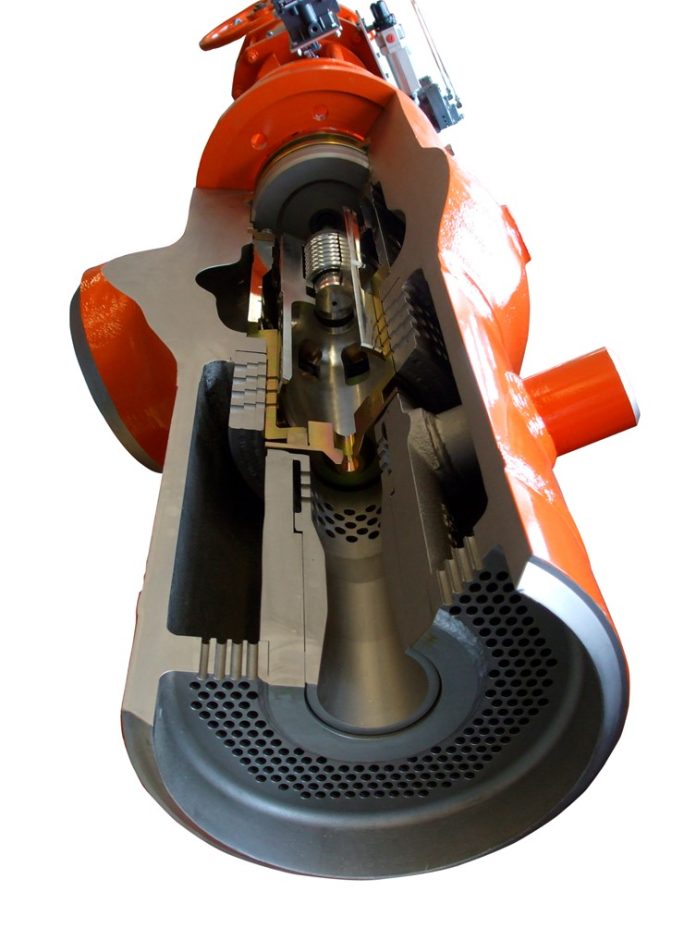

The Direct Steam Conditioning Valve – Steam Atomization (DSCV-SA) from the Copes-Vulcan brand of Celeros Flow Technology is specifically designed to meet the rigors of modern power generation using superheated steam. Already relied on in conventional power generation, refineries, and paper mills, the DSCV-SA is also finding new applications in renewables, including waste-to-energy plants.

Importantly, the DSCV-SA is not a high maintenance valve. It features a ‘Quick-Change’ style trim with no welded-in components or large internal threaded parts. The whole trim assembly is held in compression and simply removing the compression ring or bonnet allows the whole trim to slide out. Therefore in-situ maintenance, if required, is quick and simple with no need for specialized tooling or training.

Robustly designed, the DSCV-SA has a standard body-to-bonnet joint, up to ANSI 900#, which is bolted and incorporates a fully enclosed spiral wound gasket made from 300 stainless steel with graphite filler. For pressure ratings above ANSI 900# a pressure seal bonnet closure is employed, which utilizes a graphite sealing ring. The DSCV-SA is available in an almost infinite range of sizes, materials and pressure ratings as each valve is tailored to suit individual customer requirements.

The DSCV-SA can be fully rated or split rated and is available in standard, special or intermediate classes. Standard classes are available up to and including ANSI 4500# and intermediate and special class designs can be accommodated where required.

Courtesy of Celeros Flow Technology.