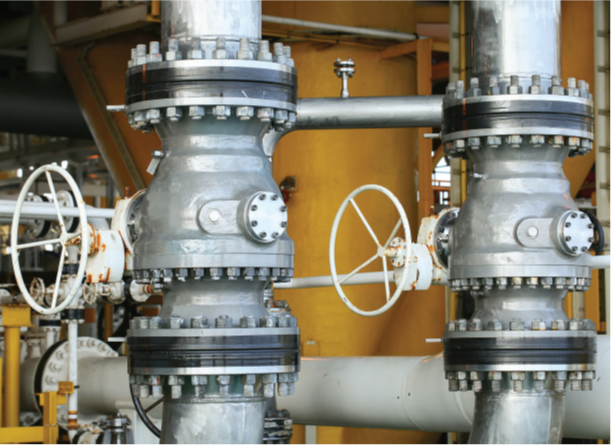

Valves play a vital role in any piping system in the chemical, oil, and gas industries. Stainless steel, with its properties of strength, ductility, corrosion and heat resistance, low maintenance, and unlimited lifecycle, has become an obvious choice due to its low cost. By adding alloys like chromium (Cr), nickel (Ni), molybdenum (Mo), manganese (Mn), and silicon (Si), stainless steel can attain higher degrees of corrosion resistance, durability, high temperature and pressure tolerance, and versatility.

Stainless steel is ideally suited for aggressive environments, which in industrial applications include pharmaceutical and food and drink manufacturing processes that take their toll on processing equipment. In such demanding applications, stainless steel is a good material for valves because of its favorable lifecycle cost.