In the intricate world of industrial piping and pressurized systems, one component silently but signifi cantly dictates the integrity and safety of operations: the gasket. Proper gasket installation is a procedure that has been historically challenging, subject to inconsistencies, inaccuracies, and prone to human errors. It is in this context that Digital Gasket Training (DGT) emerges as an innovative software solution, transforming the gasket assembly process into a captivating interactive experience.

By Leonardo Roca, Applications Engineer – Teadit Brazil

Conceived as an interactive software, DGT is a new approach to gasket assembly training. It brings the real-time elastic interactions between bolts to a vivid virtual environment, mirroring complex aspects of actual gasket assemblies. DGT not only serves as a robust educational tool but also as a compelling simulation that captures the nuances of real-world mechanics.

The software includes a built-in certificate generator that offers tangible proof of a user’s successful completion of a standardized gasket assembly method. Upon accurately calculating and performing the correct tightening steps, the software generates a personalized certificate. This serves as evidence of the user’s proficiency and incentivizes adherence to recommended gasket assembly methods.

The American Society of Mechanical Engineers (ASME) PCC-1 guideline has transitioned to a standard, which amplifies the need for consistent and standardized training. DGT fulfills this gap, serving as a much-needed platform at a time when incorrect gasket installation reigns as the leading cause of leakage in industrial settings

About Digital Gasket Training

DGT offers a software format that ensures easy accessibility across geographies while maintaining the fidelity of training equivalent to an actual bolted flange device. Adding to this versatility is the option to integrate a torque transducer device for an even more enriched user experience.

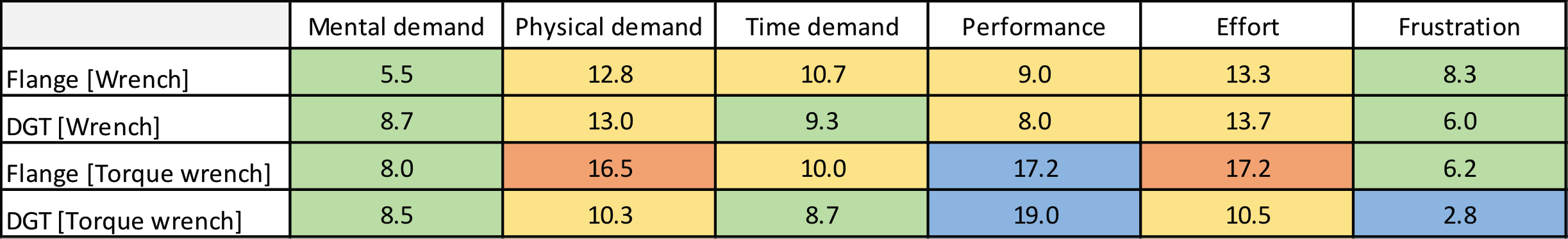

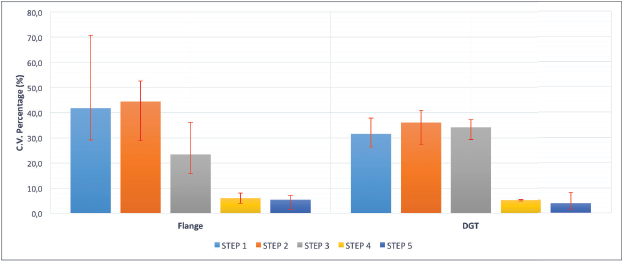

In a recent study that involved both qualitative and quantitative analyses, six participants performed gasket assemblies under varying conditions. The NASA Task Load Index (TLX) was used to assess various workload factors, such as mental and physical demand.

The study showed that the DGT was comparable to traditional training methods in terms of physical demand, even though it was somewhat more mentally demanding. This could be attributed to the interactive features of the simulator’s interface, which require users to engage more actively with the system. Overall, the DGT software was validated as an effective, accessible, and practical training tool for learning standardized gasket assembly techniques. Notably, its virtual nature brings significant advantages in terms of affordability and ease of deployment, positioning it as a compelling alternative to traditional, instrumented flange devices for educational use. Figures 2 and 3 display the qualitative and quantitative results, respectively.

The DGT’s effectiveness in mimicking real-world gasket assemblies relies on a meticulously crafted mathematical model. While finite element analysis (FEA) serves as a reference point, the actual computational underpinnings of the software are based on a simplified model. This simplified model captures the elastic interactions between bolts in real time, providing a robust framework for assembly training.

Perhaps one of the most captivating features of DGT is its ability to visualize gasket internal stresses. This aids in understanding potential leakage points, making the learning process not just theoretical but profoundly intuitive. This level of understanding has profound implications for better industrial safety and efficiency.

Final Thoughts

Digital Gasket Training has revolutionized how one approaches, understands, and executes gasket assembly procedures. It is a stunning fusion of technology with practical engineering, designed to improve safety and performance in an industry where even the smallest mistake can lead to catastrophic results. DGT stands as a testament to what is achievable when innovation meets application, and it offers an inspiring vision for the future of industrial training and standardization.