A Midwest chocolate manufacturer was losing product due to overheating. The manufacturer found that the solution involved several interesting changes, including new valves. This article is about providing the best purchaser decision options for chocolate manufacturing, starting with the understanding of each process.

By Bob McIlvaine, President & Founder – The McIlvaine Company

Making Chocolate

Chocolate is made everywhere. From South Africa and the South of France to Taiwan and rural Costa Rica, it comes from the seeds of a tropical fruit tree called Theobroma cacao. The process of chocolate making from the tree into an edible bar takes roughly a week and can be broken down into seven basic steps: harvest, fermentation, drying, roasting, winnowing, refining, and tempering.

The U.S. chocolate industry revenue has grown at a compound annual growth rate (CAGR) of 0.6% over the past five years, reaching an estimated USD $19.9bn in 2023.

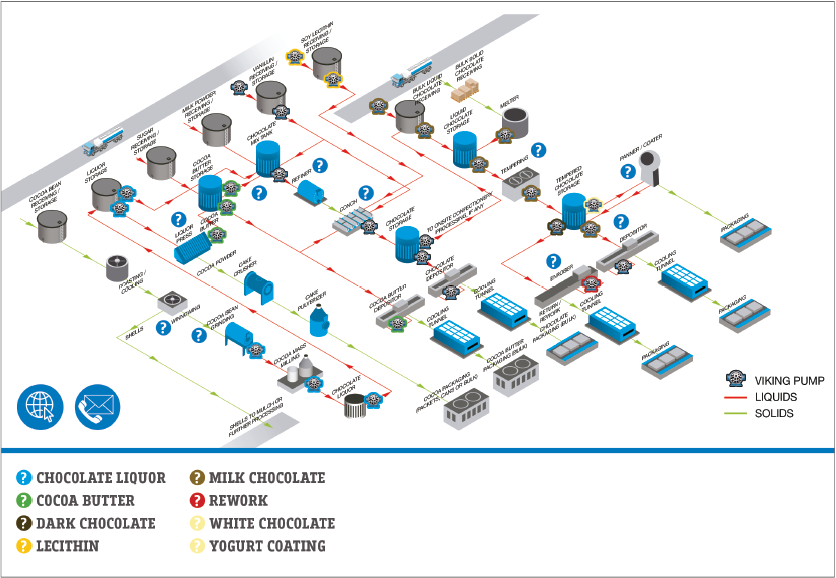

To provide the best purchaser decision for chocolate manufacturing, one must start by understanding each process. For example, Viking Pump has specialists in each niche who have a thorough knowledge of each process. Joel Fenton and Tom Ertz specialize in understanding and addressing customer needs with regard to chocolate making, including which valves to use for which applications in the process.

Valve Selection

There are two major application categories for chocolate production. One is for liquids and the other is for dry granular solids.

Liquids and Slurries

The types of valves used in liquids and slurry applications include control, isolation, and pressure relief valves. Due to the widespread use of internal gear pumps for viscous chocolate slurries, external pressure relief valves are essential.

Some gear pumps include a built-in pressure relief valve which provides the same critical pressure relief but only for very short time periods. This is because built-in pressure relief valves are internal to the gear pump and simply recirculate the liquid inside the gear pump itself. Tom Ertz warns against this option when processing chocolate. When in by-pass mode, the heat generated by the RV will caramelize the chocolate very quickly and will generally lead to the pump locking up.

External relief valves are therefore essential because the following variables change the resulting pressure:

- Pipes and fittings may corrode or build up with solids, closing off the opening size.

- Downstream filters may clog, or meters fail.

- Operators may inadvertently close or forget to open downstream valves before turning the pump on.

In each of these scenarios, the downstream pressure will increase. As a result, overpressure protection must be used. Relief valves are the most used form of overpressure protection for rotary positive displacement pumps.

A Closer Look at Relief Valves

The most common pump relief valve utilizes a spring and moving poppet. Under normal pressure, the spring holds the poppet against a machined seat, preventing liquid from bypassing. As pressure builds, eventually overcoming the spring force, the valve opens to bypass a portion of the flow.

Eventually, pressure may build to the point of opening the valve completely to bypass 100% of the pump’s flow. This point is called complete bypass pressure (or full bypass pressure). As pressure returns to normal, the spring closes the poppet, and pump outflow returns to normal. An adjusting screw allows for adjustments to the compression of the spring to change the valve pressure setting.

Dry Applications

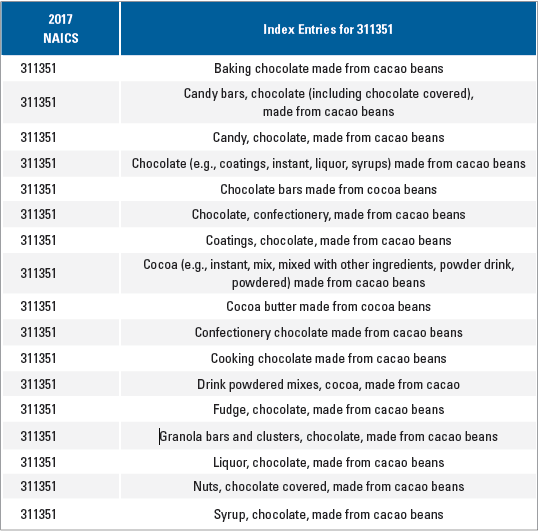

In chocolate manufacturing, as shown in Figure 3, there is a lot of powder consumed.

To close silos, hoppers, or bins containing powder or granules, Butterfly Valves range among the most widely used equipment worldwide. What used to be custom-built for specific applications, WAM has turned into a mass-produced, industrial product with features that allow extremely versatile use.

VFS Butterfly Valves, for example, are used in all types of powder and granular material processing plants where interception of gravity-fed or pneumatically conveyed dry materials is required. They are fitted beneath hoppers, bins, silos, screws, or other types of conveyors, to intercept pneumatic conveying ducts. Due to their special design and the use of engineering materials, it represents a particularly cost-effective and efficient solution.

Since maintaining temperature is critical in chocolate manufacturing, jacket valves are also necessary.

Final Words

Valves play a critical role in isolating chocolate manufacturing equipment for cleaning or shutdown. Control valves maintain the right mix of ingredients. Safety relief valves play a critical role as well.