Molten salt is a promising clean energy technology that has the potential to revolutionize the energy sector. It refers to a type of high-temperature liquid that is used in various industrial processes, including as a heat transfer fluid in solar thermal power plants and as a coolant in nuclear reactors. In solar thermal power plants, molten salt is used to store energy captured from the sun, allowing the power plant to generate electricity even when the sun is not shining. This makes it possible to deliver consistent and reliable electricity from renewable sources.

By Narayan Vasudevan, Global Engineering Leader, and Shridhar Patil, Engineering Specialist – Flowserve

A Look at Molten Salts

Molten salts are a phase change material that is commonly used for thermal energy storage. The material is solid at standard temperatures and pressures and enters a liquid phase at elevated temperatures. The most common molten salts are generally a eutectic blend of 60% sodium nitrate and 40% potassium nitrate; this becomes a liquid between 265-565°C.

Molten salts have a variety of uses. They can be used as heat transfer fluids as well as for thermal storage. They are easy to prepare, and their chemical and physical properties make them serious contenders to conventional organic liquid solvents. Some of their physical properties include thermal and chemical stability especially toward moisture, negligible pressure vapors, non-flammability, stability at high potential, and high conductivity.

Molten salts are often used with concentrated solar power (CSP) plants to store thermal energy with minimal energy loss for electricity generation. They are also used as a heat transfer fluid to generate power through the turbines.

Properties of Molten Salt

Molten salts are extensively studied in view of their unique physical and chemical properties; high chemical and thermal stability, broad electrochemical window, negligibly low vapor pressure, and ability to dissolve various solutes.

Molten salt technology is a catch-all phrase that includes some very diverse technologies: electro-chemistry, heat transfer, chemical oxidation/reduction baths, and nuclear reactors. All these technologies are linked by the general characteristics of molten salts:

- Can function as solvents,

- Have good heat transfer characteristics (heat capacity),

- Functions like a fluid (like water),

- Can attain very high temperatures, and

- Can conduct electricity.

Operating Temperature

Many different salt blends can be formed to achieve certain operating temperatures.

- Cold salt – 400°C (Stored in the salt storage tank and heated to maintain the salt above solidification temperature).

- Hot salt – 600° C (Stored in the outlet tank and used for power generation whenever required

The molten salts are formed in two ways: binary and ternary eutectic mixture of the different salts.

- The binary mixture of sodium nitrate/ potassium nitrate salt is generally used from 509° to 1,049°F (265° to 565°C) to provide enough safety factor above the freezing point. This salt will begin to experience degradation when it reaches temperatures above 1,049°F (565°C). Above that point, it will slowly degrade into nitrogen and nitrogen oxides.

- The ternary mixture of lithium nitrate/ sodium nitrate/potassium nitrate mixture is another option, with the eutectic melting temperature occurring at 266°F (130°C). The disadvantage of this mixture – compared to the binary mixture – is that it can only be used to a maximum temperature near 932°F (500°C). Above 932°F, the lithium nitrate begins to degrade. Also, substances are expensive compared to sodium or potassium salt.

When using molten salt, it is recommended that the fluid temperature be at least 36° to 54°F (20° to 30°C) above the melting point. This reduces the risk of freeze-ups where there may be cold spots. Also, it is recommended to keep the maximum operating temperature of the salt at least 36°F (20°C) below the degradation temperature.

Design Specifications for Molten Salt Valves

Molten salts are considered more challenging to use due to their melting and freezing points. With these concerns in mind, if the system is designed with proper heat trace, molten salts will provide excellent heat transfer, and minimal degradation throughout the lifetime of the system.

The fundamental process technical challenges regarding the valve used with Molten Salts are the following:

- Molten salt lines are working at high temperatures (nearly 600°C/1,115°F),

- Corrosive fluids (depending on the type of salts: Chloride, fluoride, sodium nitrate NaNO3, potassium nitrate KNO3 ),

- High flow velocity,

- High reliability & long life / no down-time required,

- Perfect tightness (inline and process/ atmosphere).

Valve Design

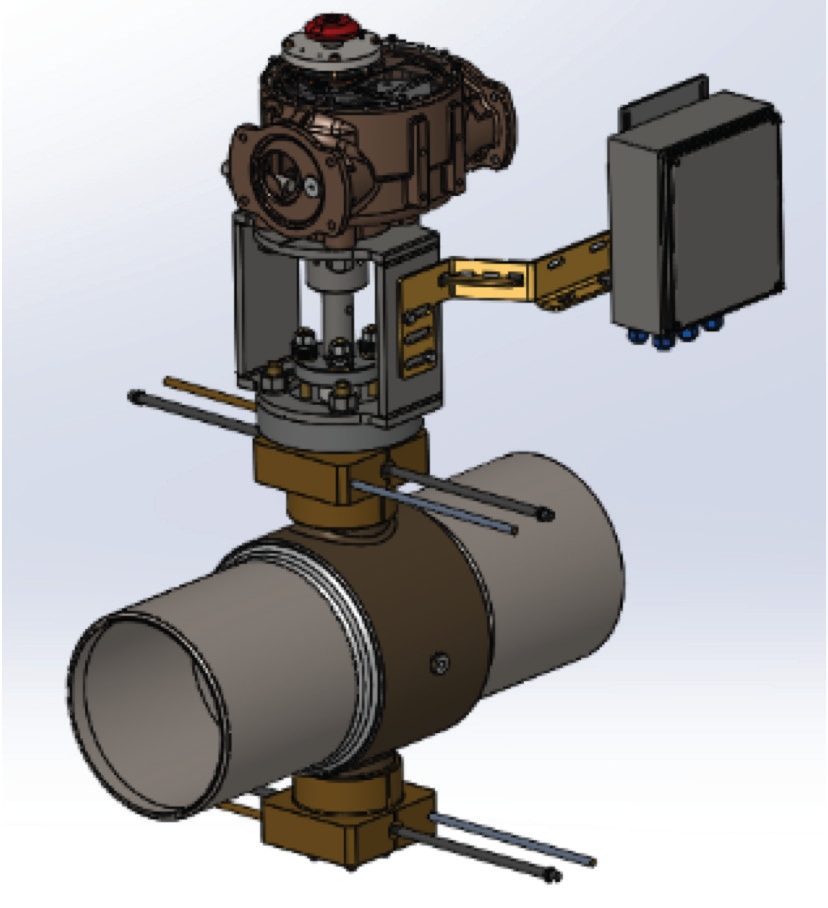

The basic and fundamental consideration regarding the valves is to maintain the temperature of the valve body wetted parts, sealing parts, and moving parts above the freezing point. This is to avoid crystallization of the molten salt while in service or operation. If the molten salt comes into contact with the valve it can result in damage to the valve internals and may cause valve seizure. Valves shall be designed for an intermittent service with about 20,000 cycles as a minimum for the required life of 25 years.

The Valve body shall be designed by considering the important factors that affect the performance of the valve:

- Butt weld end design shall be preferred to avoid the potential leak path between the flanges.

- Optimum neck height to be designed based on thermal FEA analysis and calculations.

- Body neck/guide to be designed to accommodate efficient EHT systems to keep the temperature above the salt solidification temperature, especially for cold salt application.

- The body shall have provisions to install temperature sensors to monitor critical temperatures in the packing, flow path, and bottom guide regions.

- Body joints shall be efficiently designed to avoid loosening due to vibrations and temperature fluctuations during operation.

- The stem shall be properly guided such that no lateral loads act on the stem due to misalignment that may lead to wear and galling of shaft and bearing.

- The valve shall be designed to accommodate the insulation thickness around the valve body, top neck, and bottom guide region.

Packing and Gasket Design

Molten salt is not compatible with the standard graphite-based packings, as graphite tends to oxidize and disintegrate at high temperatures. So, for molten salt application, graphite-based packing gaskets are replaced with Thermicullite packings and gaskets that are proven to withstand salt temperatures up to 1,000°C and offer good sealing at very high pressures. These packings are specially designed on a case-to-case basis and take into consideration the process and design parameters. Packing thickness and the quantity of packing are dependent on the salt pressure, temperature, and stem diameters.

Electrical Heat Tracing (EHT) and Insulation

Electrical Heat Tracing (EHT) is an important consideration in the design of Molten Salt valves. The main objective is to keep the valve hot to ensure the Salt stays in its molten state during the operation of the valve.

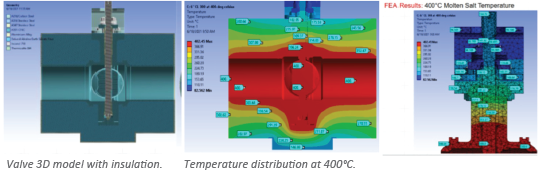

It is important to plot the temperature at various parts of the valve to determine the need for heat tracing requirements. This requirement may vary for each valve depending on the application where it is installed. For example, for a valve installed in cold salt application, the normal operating temperature is 400°C. EHT is therefore installed on 2 main regions of the valve: valve body and top neck.

The center part of the valve body is heated to ensure the temperature stays above the melting point. It is also necessary to monitor the temperature at the valve neck and the bottom closures, and provide auxiliary heating provisions, if necessary, to avoid salt freezing in these regions.

Thermal sensors need to be installed in the critical region where the temperature must be monitored.

The critical region here is the body neck which is usually extended to take the stuffing box. Any drop in temperature stuffing box which houses the packing would result in freezing of salt and would make the operation of the valve difficult and at times also may result in valve seizures.

Thermal FEA

Thermal FEA is a critical part of the de- sign process, which helps to understand thermal stress (Fig 5) at high temperatures and the temperature distribution (Fig 6) across the packing and bottom guide region. The outcome of this analysis will help to place the packing strategically such that the temperature across the packing is above salt solidification temperature. By using transient thermal analysis, we can simulate thermal shocks and study the unprecedented stresses developed on the valve body and bolting region due to rapid cooling rate during fast defocusing.

Evaluation of Valve in Molten Salt Test Loop

It is essential that each valve design undergoes validation with the associated set of packings and that the gaskets selected are tested in the molten salt loop to ensure that the valve performance is not compromised while used in the field.

The following are the objectives for testing in the molten salt loop:

- Verification of valve design regarding thermal losses, so that temperature profile over the entire valve is mapped.

- Thermal simulation through appropriate software and comparing the thermal results with the temperature map determined out of physical testing. This will enable scaling of the design to the other valve sizes.

- Determine the procedure for the sizing of the heat tracing system.

- Testing of the sealing elements to make proper selection.

- Assess the wear and corrosion resistance of the parts.

- Review the possibility of changing the packing and gaskets online for easy maintenance.

Case Study

A 6” CL300 valve was selected for evaluation in the salt loop at cold working conditions (400°C). Cold salt conditions were selected as this is considered a worst-case scenario for evaluation.

A Few key takeaways are as below depicted:

The valve successfully performed more than 9,000 thermal cycles with zero design issues.

- Thermicullite and high-temperature graphite style packings were evaluated during the test, both the packings have performed well without any failures.

- Thermicullite gaskets were installed in the disc and bottom flange regions, both have exceeded design specifications without any failures.

- Temperature was measured on the valve body, packing, and bottom guide regions, during the test. The temperatures closely match the thermal FEA results.

Final Thoughts

To use Molten Salts to deliver consistent and reliable electricity from renewable sources, it is important to consider the parameters of the valves to be used in the application. If designed and implemented accurately, the valves can ensure that the system functions well that renewable energy is provided.