The industrial valve industry is on the verge of a significant transformation as artificial intelligence (AI) technologies, such as ChatGPT, become increasingly integrated into various aspects of the world. This article explores the ways in which AI technology will revolutionize and disrupt the industrial valve industry, focusing on sales, manufacturing, and quality. We will break down both the advantages and disadvantages of this technological shift, reviewing some areas of where and how AI can streamline processes, improve efficiency, and potentially impact the workforce and overall responsibility and duties of people currently working today.

By Luke Chou, Consultant – ValveHax

Revolutionizing Customer Experience and Efficiency

Automatic Pricing and Costing Structures

A crucial aspect of the sales process is keeping track of raw material costs and updating pricing accordingly. AI technology can automatically manage these tasks, creating costing structures based on historical and estimated valve data and changing index pricing will reviewing market sentiment. This not only re- duces human error but also increases efficiency by allowing sales personnel to focus on more critical tasks, such as reviewing quotes for customers or ad- dressing other customer needs.

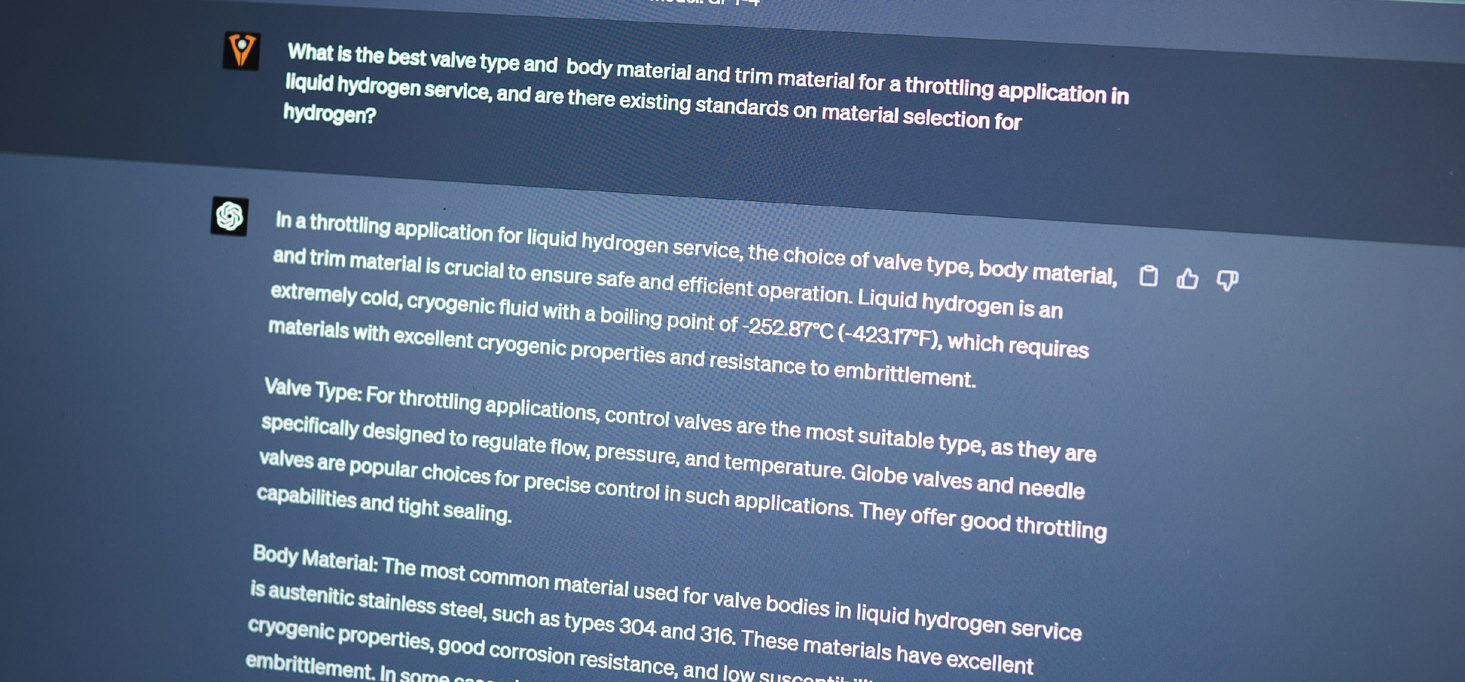

Customer Specification Analysis and Valve Selection

AI technology can automatically digest and review customer specifications, comparing them against internal standards. By leveraging expert systems trained by subject matter experts (SMEs) from various backgrounds in the valve industry, including sub-suppliers, manufacturers, contractors, and users, AI can provide valuable assistance in selecting the right valve and features for specific applications. This ensures customers receive well-informed recommendations tailored to their requirements and deviations have proper justifications.

AI-Powered Customer Support

The use of AI bots in customer support can streamline the process of obtaining relevant information and connecting customers with the right company representatives. This eliminates reliance on new or inexperienced employees, ensuring that customers receive accurate and timely assistance. AI-powered customer support can significantly improve customer satisfaction, leading to stronger long-term relationships between the company and its clients.

Streamlining Sales Documentation

By utilizing a properly trained AI, sales teams can generate essential documents, such as general assembly drawings, bills of material, suggested repair lists, and inspection and test plans (ITPs), faster and more accurately. This capability expedites project completion and enhances customer satisfaction, ensuring that projects are delivered on time and within budget. With AI handling these time-consuming tasks, sales teams can devote more attention to building relationships with customers and providing personalized support.

Enhanced Communication and Collaboration

Something often overlooked, AI can facilitate and speed up communication between sales teams and other departments within an organization by automating information sharing. This allows sales teams to stay informed about product developments, inventory levels, and other critical updates, improving their ability to manage customer expectations and negotiate contracts. Better communication also fosters a more collaborative environment, promoting synergy between departments and improving overall efficiency. For example, sentiment analysis of an email or cancellation of PO, can be set up to notify production and engineering for better planning. A sales employee who is on vacation can choose to turn their auto AI escalate to overdrive to better ensure information transfer within the company.

Streamlining Production and Identifying Improvements

Automated Production Reporting and Evaluation

AI technology can automatically summarize production data for reporting and evaluation, allowing manufacturers to gain valuable insights into their operations. By streamlining this process, AI enables companies to make data-driven decisions and implement improvements more efficiently. The use of machine learning algorithms allows AI systems to analyze large volumes of data, identifying patterns and trends that can help optimize production processes.

Continuous Process Improvement

AI systems can auto-detect potential improvements to current manufacturing processes by monitoring technological advancements, industry news, and internal process documentation. By comparing this information against existing processes, AI can suggest changes that could enhance efficiency, reduce waste, or improve product quality. This continuous process improvement helps manufacturers stay ahead of the competition and adapt to the ever-evolving demands of the market.

Optimized Production Schedules and Resource Allocation

Machine learning algorithms can be employed to optimize production schedules and resource allocation, ensuring that manufacturing processes run smoothly and efficiently. By analyzing historical data and current demand, AI systems can predict the optimal sequence of operations and allocate resources accordingly. This results in reduced waste, minimized downtime, and improved overall efficiency. As a consequence, companies can deliver products faster and at a lower cost, strengthening their position in the market.

Predictive Maintenance for Minimized Downtime

One of the most promising applications of AI in the manufacturing process is predictive maintenance. By analyzing data from sensors and equipment logs, AI can identify equipment that may require servicing or replacement before a failure occurs. This proactive approach helps manufacturers prevent unexpected equipment breakdowns and minimize disruptions to production.

Predictive maintenance also enables companies to schedule maintenance tasks more effectively, reducing the schedules. This not only saves costs as likelihood of conflicts with production associated with unplanned downtime but also extends the life of equipment, further improving the return on investment.

Quality: Standards Compliance and Inspection Efficiency

Procedure Generation and QMS Compliance

AI technology can be leveraged to develop ISO 9001 compliant procedures, ensuring that quality management systems adhere to recognized standards. By utilizing natural language processing (NLP) and machine learning algorithms, AI can analyze existing procedures, identify gaps or inconsistencies, and suggest improvements in line with ISO 9001 requirements. Furthermore, AI can streamline the process of creating new procedures by generating templates based on industry best practices and specific organizational needs. The quality team can just input what the company does in simple language and request AI to generate a procedure compliant to the industry procedure, and a fully procedure can be generated in fraction of standard time.

Streamlining ITP Management and Compliance

AI can be used to compare internal standard ITPs with customer requirements, quickly generating new ITPs as needed and estimating the cost and production impacts of these changes. By cross-checking all written procedures against global standards, AI can prevent duplicate or conflicting requirements and simplify the review process when standards are published and updated. This streamlined approach to ITP management and compliance can save time and resources, ultimately improving overall quality control.

Continuous Data Storage, Monitoring, and Analysis

It can also continuously monitor internal data to pinpoint areas of concern, such as potential product defects or process inefficiencies. By transforming different formats of datasheets and material test reports (MTRs) into a central system, AI can reduce errors and increase data retrieval speed. This enhanced data analysis capability allows companies to identify and resolve issues more quickly, ultimately improving product quality and customer satisfaction.

Sentiment Analysis for Improved Customer Support

AI can be employed to perform sentiment analysis on customer emails, automatically escalating issues based on the urgency and severity of the problem. This proactive approach ensures that critical issues are addressed promptly, improving customer support and fostering stronger relationships with clients. By addressing potential problems early on, companies can maintain a high level of product quality and minimize the risk of customer dissatisfaction.

Targeted Inspections: Shifting from Random Sampling to Probable Issue Inspection

AI technology can change the quality control process by shifting from random sampling of QC to probable issue inspection, focusing on areas more likely to have problems. This targeted approach helps companies identify and resolve issues more quickly, minimizing the likelihood of product defects reaching the end customer. By using AI to analyze historical data and production trends, companies can prioritize inspections based on the probability of defects, ultimately improving product quality and reducing the time and resources spent on inspections.

AI-Powered Computer Vision Systems for Enhanced Inspection

Integrating AI-powered computer vision systems into quality control processes can improve the inspection of valves and their components. These systems can identify defects that may be difficult for human inspectors to detect, ensuring a higher level of accuracy and consistency in the inspection process. By automating visual inspections, companies can reduce the reliance on manual labor, minimize human error, and accelerate the overall inspection process, especially for a mature and developed product.

Regulatory Concerns and Responsibility Issues

The lack of comprehensive regulations surrounding AI is a significant concern in the industrial valve industry. As AI-powered systems become more prevalent, there is an increasing need to establish guidelines and standards to ensure the safe and responsible use of this technology. One critical issue that needs to be addressed is the assignment of responsibility when AI recommendations lead to adverse outcomes, such as valve failure, plant shutdowns, or loss of life or property.

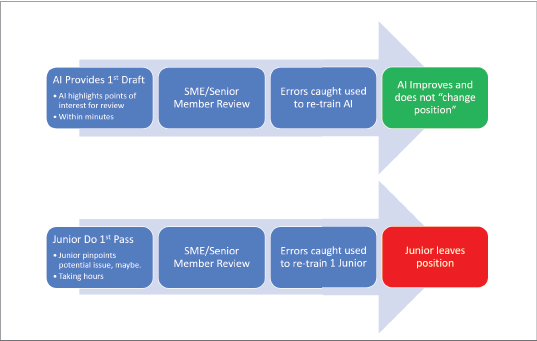

Determining who should bear responsibility in these situations is a complex matter, as it may involve multiple parties, including the AI developer, the valve manufacturer, and the end-user. Developing a regulatory framework that clearly defines the roles and responsibilities of each party is essential to ensure accountability and maintain trust in AI technology. The simplified method will be by having experience personnel fully reviewing and signing off on key AI produced information, removing AI developers from the ownership of the generated information.

Impact on Workforce Dynamics

The widespread adoption of AI technology in the industrial valve industry may have unintended consequences on workforce dynamics. As AI systems become more capable of performing tasks traditionally carried out by humans, there is a risk of job losses, particularly for less experienced personnel. This phenomenon could exacerbate the existing brain drain in the industry, as the older generation of experts leaves the workforce, and AI prevents the training of a new generation of professionals.

To mitigate this potential issue, companies must adopt a balanced approach to AI integration, focusing not only on the automation of tasks but also on the development of a skilled workforce that can effectively leverage AI technology. This may involve investing in reskilling and upskilling initiatives, as well as fostering a culture of lifelong learning within the organization.

Additionally, it is essential to recognize that AI systems can complement rather than replace human expertise, particularly in areas where human intuition, creativity, and problem-solving skills are crucial. By encouraging collaboration between AI and human experts, companies can harness the full potential of this technology while preserving the unique knowledge and skills of their workforce.

Conclusion

AI technologies like ChatGPT have the potential to revolutionize the industrial valve industry by enhancing efficiency, streamlining processes, and improving customer experiences. However, it is crucial to address potential drawbacks, such as the lack of regulation, potential brain drain in the industry, and the danger of hallucination and incorrectly generated information.