Siemens, a global leader in technology for additive manufacturing (AM) is expanding focus on AM initiatives in the United States to help accelerate the transformation of the US AM industry through serial additive manufacturing.

Siemens is focused on supporting the domestic AM machine builder community, so is bringing its world-class motion control, automation hardware, digitalization software and technology capabilities to assist machine builders. From its Charlotte Advanced Technology Collaboration Hub (CATCH), located in Charlotte, North Carolina, Siemens will act as an ecosystem platform for machine builders, machine users and additive design engineers alike.

Siemens can assist AM job shops as well as Tier One production facilities with end-to-end solutions, including product design software, digital twin machine simulation and virtual execution of manufacturing methods, with full data feedback into the design protocol for necessary adjustments, prior to any machine building.

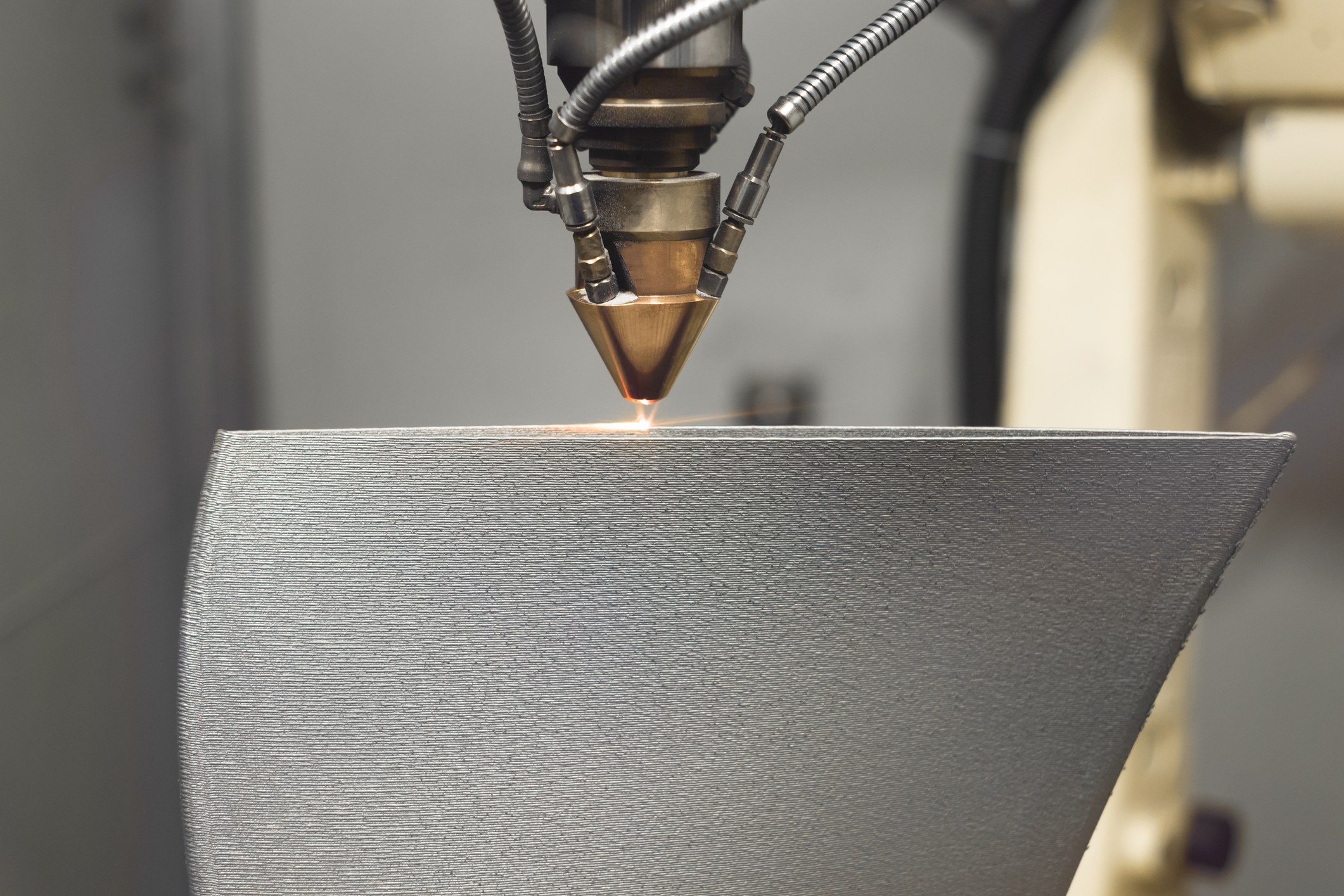

Siemens is adding technology to CATCH to incorporate metal binder jet technology through the purchase and installation of an ExOne/Desktop Metal Production System and Meltio Robotic System with the Siemens SINUMERIK RunMyRobot application onboard. SINUMERIK RunMyRobot controls the kinematic path of an industrial robot as it integrates with the CNC machine.

Siemens is also establishing an Additive Manufacturing Advisory Board of renowned industry leaders in AM, drawn from various industries and technical disciplines, to provide the company guidance, as it seeks to support the fast-growing needs of the AM market.

Courtesy of Siemens.